UV Direct-to-Film (UV DTF) printing is at the forefront of transforming the custom apparel industry, showcasing the latest advancements in digital printing technology. This innovative method leverages UV-curable inks to create vivid and durable designs on various substrates, from t-shirts to tote bags, making it an essential tool for modern apparel businesses. As the demand for high-quality products surges, UV DTF offers unparalleled printing advantages that cater to both aesthetic appeal and lasting wear. Additionally, UV DTF stands out as an eco-friendly printing method, reducing harmful VOC emissions commonly associated with traditional printing processes. This blend of customization, efficiency, and sustainability positions UV DTF as a pivotal player in meeting the evolving needs of consumers.

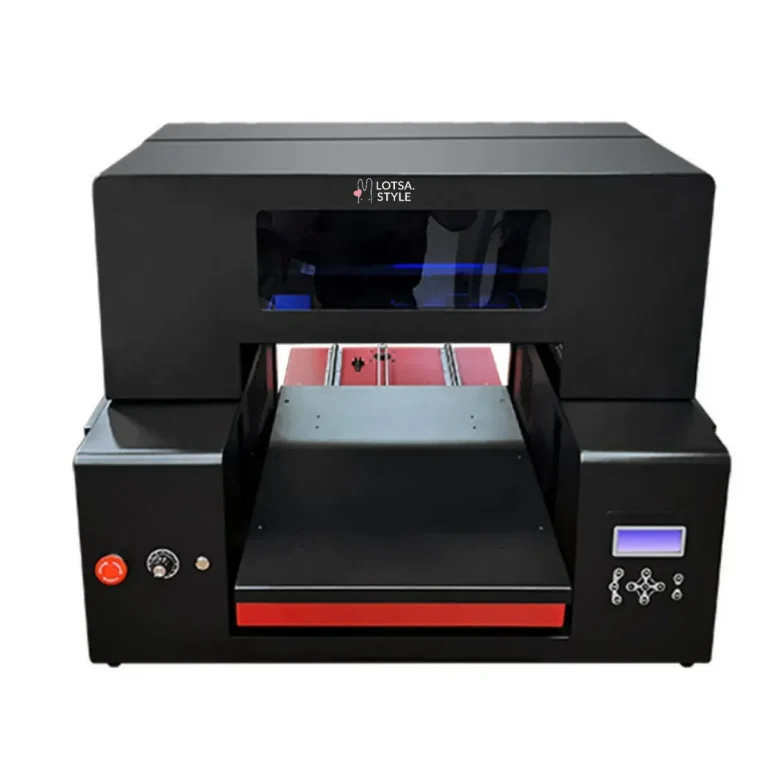

Known as UV Direct-to-Film technology, this method revolutionizes garment decoration by employing UV inks that cure instantly under ultraviolet light. Its ability to print on a diverse array of materials, combined with exceptional durability, underscores why more businesses are adopting this state-of-the-art custom apparel technology. The growing popularity of eco-friendly printing methods also highlights UV DTF’s contribution to sustainable manufacturing practices, ensuring high-quality prints that are both vibrant and long-lasting. With the trend toward immediate customization becoming increasingly prevalent, the flexibility of UV DTF allows brands to efficiently respond to consumer demands. Consequently, this cutting-edge technology not only enhances the quality of products but also redefines the prospects for future innovations in the apparel sector.

The Evolution of Printing: Introducing UV DTF Technology

The custom apparel industry has undergone significant transformation owing to innovations like UV Direct-to-Film (UV DTF) technology, which represents a significant leap forward in printing techniques. This method employs UV-curable inks that solidify instantly upon exposure to UV light. The result is a vibrant, long-lasting image that adheres well across a variety of materials. Some of the most common substrates for UV DTF include cotton, polyester, and even non-fabric surfaces like leather and acrylic, making it a multifaceted solution for modern businesses aiming to produce high-quality custom apparel.

In comparison to traditional printing methods, UV DTF offers impressive adaptability, enabling manufacturers to effortlessly switch between different endeavors without compromising quality. This versatility not only enhances production capabilities but also serves to attract customers seeking unique personalized items. As the market becomes increasingly competitive, adopting such advanced technologies is crucial to meeting and exceeding consumer expectations for quality and variety.

Key Advantages of UV DTF Printing in Custom Apparel

UV DTF technology stands out due to its remarkable advantages over traditional printing methods. One of the primary benefits is the heightened quality and durability of the prints themselves. With UV DTF, garments are adorned with colors that retain their vibrancy despite repeated wash cycles. This longevity makes it particularly appealing for custom apparel, where customers often expect their clothing to withstand time and use without losing its visual appeal.

Moreover, the resilience of UV DTF prints translates to cost-effective solutions for businesses. By minimizing issues such as fading or cracking, companies can significantly reduce returns or customer complaints — ultimately protecting their bottom line. Thus, for entrepreneurs in the custom apparel space, utilizing UV Direct-to-Film printing represents not just a commitment to quality, but also a smart investment in sustainable practices and profitability.

Exploring the Eco-Friendly Aspects of UV DTF Technology

As the global community shifts towards more sustainable practices, UV DTF printing technology emerges as a leader in eco-friendly custom apparel solutions. Unlike solvent-based inks, UV inks used in the DTF process emit fewer volatile organic compounds (VOCs). This significantly lowers environmental impact, demonstrating a commitment to cleaner production methods that benefit both manufacturers and their communities.

Furthermore, the reduction of material waste associated with UV DTF printing supports eco-conscious consumer behavior. Businesses that adopt such printing technologies can promote their adherence to sustainable practices, appealing to environmentally aware customers. This not only aligns with market trends but also positions brands as responsible leaders in an increasingly eco-sensitive marketplace.

Durability and Longevity: The Future of Custom Apparel Prints

When discussing the longevity of garment printing, one cannot overlook the durability offered by UV DTF technology. The infusion of UV-cured inks ensures prints are not only resistant to wear and tear but also maintain their vividness over time. Unlike traditional methods where wear can lead to fading and peeling, UV DTF prints remain robust — an essential aspect for businesses looking to ensure customer satisfaction over the lifespan of the apparel.

This durability is particularly beneficial in a market that demands high-quality custom apparel, especially for promotional products or limited-edition runs where longevity is a crucial selling point. Brands utilizing UV DTF can assure customers of their investment, leading to increased trust and repeat business. The result? A dynamic marketplace where customers know they are obtaining apparel that is built to last.

Market Trends: Adoption and Growth of UV DTF Technologies

The adoption of UV DTF technology in the custom apparel industry mirrors broader market trends towards personalization and high-quality products. As businesses increasingly recognize the advantages of UV DTF printing, adoption rates have surged, particularly within small to medium-sized enterprises. The technology’s affordability and ease of integration into existing production lines make it an attractive option for those looking to differentiate their offerings in a competitive landscape.

Experts predict that this growth trajectory will continue, propelled by the demand for innovative and sustainable printing solutions. The work of companies using UV DTF reflects a growing interest in creating unique, high-quality garments that resonate with consumers, highlighting the fact that such technology is no longer just an optional tool but a necessity for businesses aspiring to thrive in the evolving apparel market.

Case Studies: Success Stories in Implementing UV DTF Printing

The impact of UV DTF technology on the custom apparel industry can be prominently highlighted through various success stories of businesses that chose to adopt this innovative approach. For instance, XYZ Apparel, a small custom T-shirt company switched from traditional screen printing to UV DTF. This move allowed them to drastically cut their production times by 50%, leading to owner satisfaction as they could fulfill larger orders efficiently, demonstrating how this technology can drastically improve operational efficiencies.

Similarly, Fashion Forward Co. embraced UV DTF technology to bring uniqueness to their offerings while appealing to the eco-conscious consumer market. By utilizing UV DTF, they successfully captivated a diverse clientele looking for sustainable yet stylish apparel. The result was a significant rise in both sales and customer satisfaction, reinforcing the narrative that technology can be a key differentiator in the custom apparel industry.

Frequently Asked Questions

What is UV DTF and how does it benefit custom apparel printing?

UV Direct-to-Film (UV DTF) is a cutting-edge printing technology that uses UV-curable inks to create high-quality prints on various fabrics. This method enhances custom apparel printing by providing vibrant colors, long-lasting durability, and the ability to print on multiple substrates, making it a versatile choice for apparel businesses.

What are the main advantages of using UV Direct-to-Film technology for garment printing?

The main advantages of UV Direct-to-Film (UV DTF) technology include superior durability, vibrant color quality, versatility across different materials, eco-friendly ink options with reduced VOC emissions, and cost efficiency through precise ink usage. These benefits make UV DTF an ideal choice for manufacturers in the custom apparel industry.

Why is UV DTF considered an eco-friendly printing method?

UV DTF is regarded as an eco-friendly printing method because it utilizes UV inks that emit fewer volatile organic compounds (VOCs) than traditional solvent-based inks. This reduction in harmful emissions contributes to a safer environment, aligning with growing sustainability trends in the custom apparel industry.

How does UV DTF technology improve the customization process for apparel businesses?

UV Direct-to-Film (UV DTF) technology enhances the customization process by allowing on-demand printing without extensive setup times. This flexibility enables apparel businesses to respond quickly to customer requests and produce personalized items efficiently, catering to the rising trend of fast fashion and individual consumer preferences.

In what ways does UV DTF printing differ from traditional garment printing methods?

UV DTF printing differs from traditional methods by utilizing UV-curable inks that are instantly cured with UV light, resulting in faster production speeds and more durable prints. Unlike traditional methods, which may struggle with color fidelity and wash durability, UV DTF offers superior quality and adaptability across various materials.

What industries can benefit from UV Direct-to-Film printing technology?

Various industries can benefit from UV Direct-to-Film (UV DTF) printing technology, particularly custom apparel, promotional merchandise, and fashion. Its versatility allows for printing on T-shirts, bags, and even home décor, making it an excellent choice for businesses looking to expand product offerings while ensuring high-quality, durable prints.

| Key Point | Details |

|---|---|

| Introduction | UV DTF is revolutionizing custom apparel with high-quality prints on various substrates. |

| Technology Overview | Uses UV-curable inks for fast, efficient printing on multiple materials like cotton, leather, and acrylic. |

| Key Advantages | 1. Enhanced quality and durability 2. Versatile across materials 3. Eco-friendly solutions 4. Cost-effective production 5. Real-time customization |

| Market Trends | Significant growth among small and medium enterprises adopting UV DTF for production. |

| Case Studies | 1. XYZ Apparel reduced production times by 50% with UV DTF. 2. Fashion Forward Co. boosted sales by integrating UV DTF for unique designs. |

| Conclusion | UV DTF is transforming the custom apparel industry, addressing production challenges and consumer demands. |

Summary

UV DTF is revolutionizing the custom apparel industry with its advanced printing capabilities, offering businesses the opportunity to produce high-quality, durable, and eco-friendly designs. By utilizing UV-curable inks, this innovative technology caters to a wide range of materials while promoting efficiency and cost-effectiveness. As more businesses adopt UV DTF, we are witnessing a significant shift towards personalized and sustainable fashion. The future of custom apparel looks bright as UV DTF continues to reshape industry standards and consumer expectations.