UV DTF Technology is revolutionizing the world of custom apparel printing by integrating cutting-edge innovations with high-quality output. This advanced technique harnesses ultraviolet light to cure inks for vibrant, durable prints on a variety of fabrics, making it a game-changer in the apparel printing technology landscape. With the ability to produce mesmerizing designs rapidly, UV DTF is at the forefront of DTF printing innovations that cater to the demand for personalized clothing. As brands and individual creators tap into this technology, we are witnessing exciting fashion printing trends that prioritize unique expression and creativity. Explore how UV DTF Technology is not just changing how we print but also reshaping the entire fashion industry.

The emergence of UV DTF technology marks a significant chapter in the evolution of garment printing methods, particularly for businesses looking to enhance their product offerings. By utilizing direct-to-film printing techniques, this technology allows for producing striking and resilient designs that meet the needs of an increasingly discerning consumer base. As the fashion landscape shifts towards more personalized experiences, various printing advancements are unlocking new possibilities for unique and customized clothing solutions. This approach not only fulfills the demand for apparel printing technology that prioritizes quality but also aligns with the growing trend of consumer engagement in fashion. Discover how these innovations pave the way for a more vibrant and personalized approach to clothing in today’s market.

Understanding UV DTF Technology

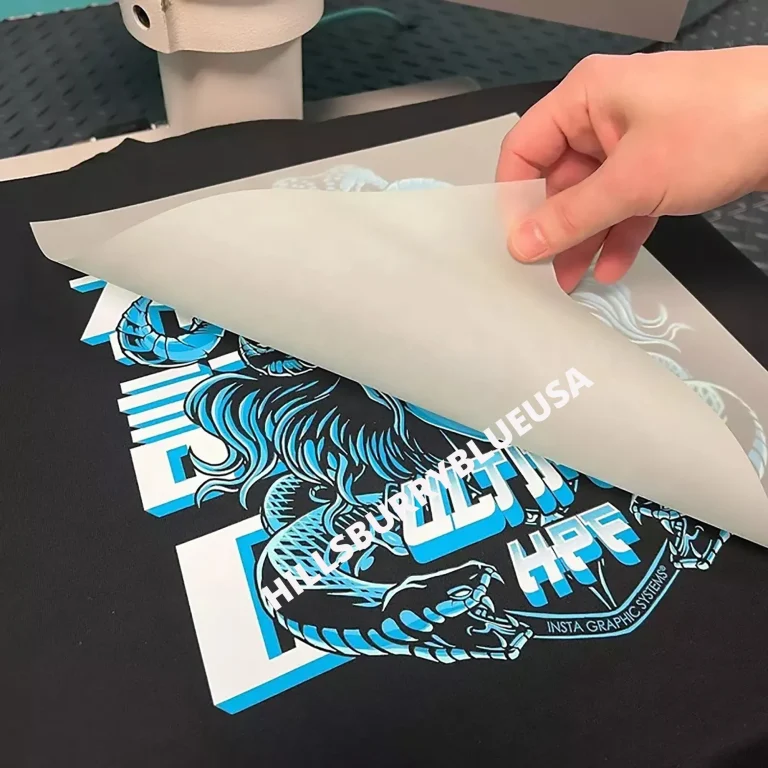

UV DTF (Direct to Film) technology is an avant-garde approach to printing where ultraviolet light cures the ink as it is transferred onto various surfaces, including fabrics. This means that the finished prints are not only vibrant and sharp, but also have a remarkable durability that stands up to the rigors of everyday wear. Unlike conventional custom apparel printing methods, UV DTF leverages the unique properties of UV light to instantly cure inks, enabling designers to produce intricate and colorful designs efficiently. This innovative printing method opens the door to a wider array of printing materials, allowing for robust applications in the fashion industry.

The adoption of UV DTF technology is not merely a trend; it represents a paradigm shift in the realm of apparel printing. The flexibility and speed of this printing technique cater to the evolving demands of consumers who seek personalized clothing options. By reducing the time required for design transitions and offering exceptional print quality, businesses can quickly adapt to the fast-paced fashion world. Moreover, as the technology matures, we can expect to see even more creative possibilities emerge, solidifying UV DTF as a cornerstone of contemporary apparel printing.

The Advantages of UV DTF in Custom Apparel Printing

One of the standout features of UV DTF technology is its ability to deliver superior print quality. The curing process allows inks to lock in vibrant colors, producing striking images that resonate with consumers seeking personalized clothing. The inks used in this technique adhere strongly to the substrate, which enhances color vibrancy and detail. Whether it’s detailed graphics for sports jerseys or intricate designs for fashion apparel, UV DTF ensures that prints maintain their integrity over time, even after numerous washes.

Additionally, UV DTF technology significantly reduces the production time compared to traditional printing methods, making it a boon for businesses that require quick turnarounds. This efficiency means that custom apparel can be produced rapidly, meeting customer demands without sacrificing quality. The scalability of this technology also allows companies to manage larger orders with ease, supporting trends in fashion printing that prioritize speed and responsiveness in meeting market needs.

Recent Innovations in DTF Printing Technology

Innovations in DTF printing technology are reshaping the landscape of custom apparel. Companies like Eazydtf and DTFPrinter are at the forefront of these advancements, expanding their capabilities to cater to diverse consumer needs. For instance, Eazydtf’s recent investment in new large-format printers demonstrates a commitment to enhancing service offerings, ensuring that businesses can fulfill customer requests efficiently and with high-quality output. Such investments signal a growing recognition of the potential of DTF technology to meet fast-paced market demands.

Moreover, the introduction of user-friendly services by companies like DTFPrinter is a game-changer for crafters and small businesses, promoting democratized access to high-quality printing. These services simplify the custom design process, allowing individual creators to focus more on creativity and less on technical logistics. This innovation fuels the ongoing trend of personalized clothing, where consumers are increasingly inclined towards unique garments that reflect their individual identities.

Challenges Facing UV DTF Technology Adoption

Despite its numerous advantages, the broad adoption of UV DTF technology comes with its own set of challenges. One significant hurdle is the initial investment in high-quality equipment, which can be prohibitive for small businesses and startups. Many industry players also face learning curves related to the use of new technologies and ensuring quality control throughout the printing process. As the adoption of UV DTF grows, these challenges must be addressed to unlock the full potential of this technology in the competitive landscape of custom apparel.

Furthermore, ensuring consistency in prints remains a key concern for many businesses venturing into UV DTF technology. As various substrates can affect the final output, finding the right balance of ink formulations and substrate compatibility is critical. The industry must focus on research and development to refine these processes, especially in relation to maintaining eco-friendly practices and reducing waste, factors highly sought after by today’s environmentally conscious consumers.

The Future of Personalized Clothing with UV DTF Technology

Looking ahead, UV DTF technology is poised to revolutionize the future of personalized clothing in remarkable ways. As customers increasingly demand unique fashion statements, the printing method offers the means to create distinctive designs that cater to individual tastes. By empowering consumers and businesses alike with advanced customization options, UV DTF is likely to influence fashion printing trends, leading to a more personalized shopping experience.

In addition to enhancing creativity, the future of UV DTF technology is also closely tied to sustainability practices. As global consciousness around environmental impacts grows, the apparel industry is seen shifting towards eco-friendly materials and printing processes. Innovations in UV inks that minimize harmful emissions are paving the way for sustainable solutions in custom apparel production. This alignment with consumer values not only sets the stage for long-term adoption but also reinforces the role of UV DTF technology as a key player in fostering responsible fashion practices.

Frequently Asked Questions

What are the key advantages of UV DTF technology in custom apparel printing?

UV DTF technology offers several advantages for custom apparel printing, including vibrant colors, faster production times, and the ability to print on various materials. This technology enhances the quality of prints, making them more durable and visually appealing, while also allowing businesses to meet urgent customer demands efficiently.

How does UV DTF technology compare to traditional printing methods for apparel?

Compared to traditional printing methods, UV DTF technology provides superior quality and efficiency. It uses UV light to cure inks instantly, resulting in sharper images and faster production cycles. This innovation reduces setup times and waste, making it a cost-effective solution for custom apparel businesses.

What types of materials can be used with UV DTF printing in personalized clothing?

UV DTF printing is versatile and can be used on a variety of materials, including cotton, polyester, blends, and even non-textile surfaces. This adaptability makes it an excellent choice for creating personalized clothing and promotional items.

How has the rise of UV DTF technology impacted fashion printing trends?

The rise of UV DTF technology is reshaping fashion printing trends by enabling unique and customized designs at scale. As businesses adopt this technology, there is an increasing focus on personalization and individual expression, allowing consumers to access more bespoke apparel options than ever before.

What recent innovations in UV DTF technology are shaping the custom apparel market?

Recent innovations in UV DTF technology include the launch of user-friendly printers catering to small businesses and crafters, as well as advancements that enhance print quality and efficiency. Companies like Eazydtf and DTFPrinter are leading these developments, enabling faster, high-quality production of custom apparel.

Is UV DTF technology an eco-friendly option for apparel printing?

Yes, UV DTF technology can be considered an eco-friendly option for apparel printing. Many modern UV inks are formulated to have lower levels of volatile organic compounds (VOCs), aligning with consumer preferences for sustainable practices. This focus on environmentally friendly production methods is becoming increasingly important in the fashion industry.

| Aspect | Details |

|---|---|

| What is UV DTF Technology? | A method of printing using ultraviolet light to cure ink on transfer materials, resulting in vibrant, durable designs. |

| Recent Developments | Major companies are investing in expanding their UV DTF capabilities, enhancing service offerings and accessibility for small businesses and crafters. |

| Benefits | 1. Quality and vibrancy 2. Speed and efficiency 3. Versatility 4. Cost-effectiveness 5. Eco-friendly practices |

| Market Impact | UV DTF technology enables personalization and customization at scale, allowing small businesses to thrive and consumers to express individuality through apparel. |

| Challenges | Quality control, initial investment costs, and personnel training may hinder adoption despite the technology’s advantages. |

| Future Directions | Anticipated advancements in ink formulation and eco-friendly practices will enhance the UV DTF printing experience and sustainability in the industry. |

Summary

UV DTF technology is revolutionizing the realm of custom apparel printing by providing unparalleled quality, efficiency, and customization options. This innovative printing method, characterized by its use of ultraviolet light to cure inks, ensures vibrant and long-lasting prints on a variety of materials. As businesses invest in this technology, they are not only lowering the barriers to entry for high-quality custom apparel but also meeting the evolving demands of consumers for personalized and eco-conscious designs. The implications of UV DTF technology extend into various markets, empowering small creators and companies alike to enhance their offerings with unique and expressive apparel. As we look toward the future, the continued development of UV DTF technology promises to reshape the fashion industry, making it an indispensable resource for both creators and customers striving for individuality in their clothing choices.