UV DTF technology is revolutionizing the printing industry by blending innovation with quality, making it a game-changer for businesses seeking a competitive edge. This advanced form of UV Direct-to-Film printing utilizes cutting-edge techniques that allow for stunning color vibrancy and enhanced resolution, appealing to the growing demand for customization in printing. With eco-friendly inks emerging as a major trend within this technology, businesses can now align their operations with sustainability goals while providing superior print quality. As we approach 2025, keeping abreast of direct-to-film trends will be essential for companies aiming to meet market expectations and attract eco-conscious consumers. In this article, we will delve into the key aspects of UV DTF technology that are paving the way for the future of printing.

The landscape of modern printing is witnessing a significant transformation with the advent of UV Direct-to-Film processes. This innovative approach to printing not only emphasizes high-quality outputs but also reflects a growing awareness of environmental sustainability. As industries increasingly adopt direct-to-film methodologies, the use of green inks and efficient production techniques are stepping into the spotlight. Moreover, the versatility of this technology allows for printing on a range of surfaces, catering to the rising demand for tailored products. In this discussion, we will explore these emerging dynamics that are shaping the future trajectory of DTF printing.

Understanding UV DTF Technology

UV Direct-to-Film (DTF) technology represents the latest evolution in the printing sector, characterized by its ability to produce high-quality prints on various substrates. This technique employs ultraviolet light to cure inks as they are printed, which drastically improves adhesion and durability across a range of materials, including textiles, plastics, and metals. The growing popularity of UV DTF technology highlights a shift towards methods that not only enhance print quality but also allow for a greater degree of creativity and customization in printing.

By harnessing advanced digital printing strategies, UV DTF technology ensures vibrant colors and intricate designs that meet consumer expectations for quality and detail. Businesses implementing this technology benefit from reduced set-up times and a streamlined production process, making it a compelling choice for companies aspiring to stand out in competitive markets. The ability to print on varied substrates further broadens the scope of product offerings, creating new opportunities for customization and personalized printing.

Trends in Print Quality Enhancements

The trend towards enhanced print quality in UV DTF printing is undeniable, with focuses on achieving exceptional resolution and vivid color reproduction. With the continuous innovation in printer technology and ink formulations, businesses are now able to produce prints that boast striking detail, surpassing the capabilities of traditional printing methods. New formulations of eco-friendly inks designed for improved adhesion not only contribute to print longevity but also maintain the vibrancy of colors, which is vital for businesses prioritizing high-quality aesthetics.

Moreover, as consumers become more discerning about the products they purchase, companies must elevate their print quality to keep pace with evolving expectations. This demand for quality has led to advancements such as improved color matching systems and the integration of precision engineering in print heads, enabling printers to create outputs that are not only visually appealing but also technically superior, addressing all aspects of quality in UV DTF technology.

Adoption of Eco-Friendly Inks

Eco-friendly inks are at the forefront of UV DTF printing, establishing a trend that targets sustainability in production while maintaining high print quality. These inks, characterized by low volatile organic compound (VOC) formulations, significantly reduce the environmental impact of printing operations. As market regulations tighten around environmental practices, embracing eco-friendly inks has become a strategic advantage for businesses seeking to enhance their reputation in sustainability while attracting the growing demographic of eco-conscious consumers.

The shift towards eco-friendly inks not only aligns with corporate social responsibility goals but also meets the rising consumer demand for sustainable products. By utilizing these inks, companies can demonstrate their commitment to environmentally responsible practices. This trend fosters a sense of trust and loyalty among consumers who value sustainability, providing businesses with a significant competitive edge in an ever-evolving marketplace that increasingly prioritizes green solutions.

Increasing Speed and Efficiency in Production

In the realm of UV DTF technology, the urgent need for speed and efficiency is transforming production lines, allowing businesses to meet rising consumer demands without compromising print quality. Recent developments in printing technology have led to systems capable of generating outputs at unprecedented speeds while maintaining strict quality controls. Automated processes associated with UV DTF printing enhance throughput, reducing production times and increasing the amount of output per hour.

This significant improvement in operational efficiency allows printing companies to adapt swiftly to market changes. By implementing advanced digital workflows and state-of-the-art printing hardware, businesses can ultimately satisfy growing order volumes while cutting operational costs. In this way, the push for speed and efficiency within UV DTF technology not only aligns with the demands of modern print service providers but also underpins profitable business growth.

Exploring Versatile Applications across Substrates

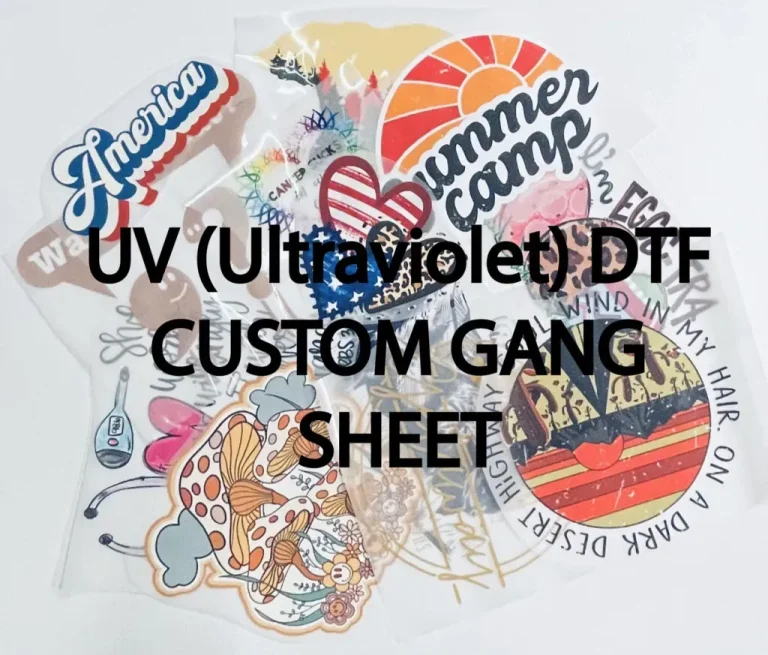

One of the marquee features of UV DTF technology is its unmatched versatility, enabling printing on a wide array of substrates that include textiles, metals, plastics, and even wood. This adaptability unlocks a myriad of applications, allowing businesses to cater to diverse markets such as industrial décor, promotional products, and signage. The capability to print on rigid surfaces significantly broadens market possibilities, positioning businesses to explore new revenue streams and niche offerings that were previously out of reach.

As companies continue to diversify their product lines, the versatility of UV DTF technology becomes a pivotal differentiator. By embracing various substrates, they can attract a wider customer base, meeting specific client needs for customization across different industries. This not only strengthens brand loyalty but also establishes a distinct market presence that resonates with both individual consumers and businesses seeking tailored solutions.

The Role of Customization in Printing

Customization is a growing trend that is reshaping UV DTF technology, permitting businesses to offer personalized products that resonate with their customers’ unique preferences. The convergence of advanced printing technology with consumer demand for individuality has ignited a creative renaissance in the printing industry. With UV DTF, companies can easily adapt designs to reflect personal branding or specific customer requests, thereby elevating consumer engagement and satisfaction.

As highlighted in recent industry analyses, the ability to provide customized solutions is pivotal for businesses looking to differentiate themselves in competitive landscapes. This trend not only caters to the desire for personalization but also allows companies to respond dynamically to shifting market demands. By leveraging UV DTF technology, businesses can maximize their market appeal, turning consumer insights into tangible product offerings that stand out in an increasingly saturated market.

Frequently Asked Questions

What is UV DTF printing technology and how does it differ from traditional printing methods?

UV Direct-to-Film (DTF) printing technology utilizes UV light to cure or dry inks as they are printed onto various substrates. Unlike traditional printing methods that rely on water-based or solvent inks, UV DTF printing employs eco-friendly inks that instantly bond and dry, resulting in higher resolution images and enhanced print quality. This method also allows for printing on diverse materials including textiles, metals, and plastics, making it more versatile than conventional printing.

How does UV DTF technology improve print quality compared to traditional printing methods?

UV DTF technology enhances print quality through advanced ink formulations that provide better adhesion, durability, and vibrancy. These inks ensure higher color accuracy and resolution, allowing businesses to achieve stunning detail and vibrance that traditional printing methods often can’t compete with. This improvement in print quality meets the demands of businesses prioritizing aesthetics and functionality in their products.

Are eco-friendly inks used in UV DTF printing sustainable and what are their benefits?

Yes, the eco-friendly inks used in UV DTF printing are designed to be low in volatile organic compounds (VOCs), minimizing environmental impact. These inks not only ensure compliance with regulatory standards but also contribute to a company’s commitment to sustainability. The benefits include improved market reputation, the attraction of environmentally-conscious consumers, and a reduced ecological footprint, aligning business practices with global sustainability goals.

How does UV DTF printing technology enhance speed and efficiency in production?

UV DTF printing technology significantly boosts speed and efficiency through innovations in hardware and software that minimize production times without compromising quality. Fast setup and reduced downtime during print runs allow businesses to produce high volumes quickly. This efficiency is crucial for meeting the increasing demand from consumers, maximizing operational output, and enhancing profitability.

What are the advantages of UV DTF technology in terms of customization and personalization?

The UV DTF technology excels in customization and personalization, facilitating cost-effective production of unique designs. Businesses can easily respond to market trends and consumer preferences by offering tailored products. This capability allows for greater differentiation in competitive markets, positioning companies to attract customers looking for personalized apparel and promotional items.

What is the future outlook for the UV DTF printing market and its significance?

The UV DTF printing market is poised for significant growth as businesses increasingly adopt this technology for its high-quality, versatile, and eco-friendly printing capabilities. This shift from traditional methods highlights the importance of adapting to technological advancements and understanding market dynamics. Companies that embrace UV DTF technology will benefit from expanded market opportunities, positioning them competitively in the evolving printing landscape.

| Key Trend | Description |

|---|---|

| Enhanced Print Quality | Recent advancements have led to better resolution, color vibrancy, and durability, meeting high consumer expectations. |

| Eco-Friendly Inks | Low-VOC inks minimize environmental impact while maintaining quality, aligning with sustainability trends. |

| Speed and Efficiency | Innovations have reduced production times and increased output, enhancing operational efficiency. |

| Increased Versatility | Ability to print on various substrates opens new market opportunities, expanding business capabilities. |

| Integration with Automation | Automation reduces labor costs and errors, streamlining production processes. |

| Customization and Personalization | Easier customization meets consumer demands for unique products, enhancing competitiveness. |

| Market Growth | The UV DTF printing market is set for significant growth as businesses adopt new technologies. |

Summary

UV DTF Technology is reshaping the future of printing with its innovative developments and trends. As companies navigate the evolving landscape, key trends highlight the importance of enhanced print quality, eco-friendly practices, efficiency, versatility, automation integration, and demand for customization. By embracing these advancements, businesses not only meet growing consumer demands but also secure a competitive edge in a market that increasingly values sustainability and quality. As we look towards 2025, it’s clear that the UV DTF technology will play a pivotal role in determining the success of printing operations around the world.