UV DTF technology is revolutionizing the custom apparel industry by combining innovative techniques in printing with a commitment to sustainability. This advanced method of Direct to Film printing utilizes UV light to cure inks instantly, producing vibrant, high-quality graphics that are both durable and versatile. As consumers increasingly seek fashion customization options, UV DTF printing offers a fast, efficient solution that meets their demands for unique and personalized designs. Notably, this sustainable printing technology reduces waste and energy usage, making it an environmentally friendly alternative compared to traditional methods like screen printing. In this evolving landscape, UV DTF is not just a passing trend; it represents the future of custom apparel, merging artistry with ecological responsibility.

Also known as ultraviolet Direct to Film printing, UV DTF technology stands at the intersection of innovation and sustainability in the world of custom fashion. This modern approach streamlines the printing process while allowing for stunning designs that cater to individual tastes and preferences. As brands adapt to the growing demand for personalized apparel, the efficiency and quality offered by UV printing techniques come to the forefront. This trend toward eco-friendly printing practices emphasizes how consumers are now prioritizing sustainable options, reshaping the future of the apparel industry. Ultimately, the emergence of UV DTF positions itself as a key player in the drive toward a more customizable and environmentally conscious fashion landscape.

Understanding the Mechanics of UV DTF Printing

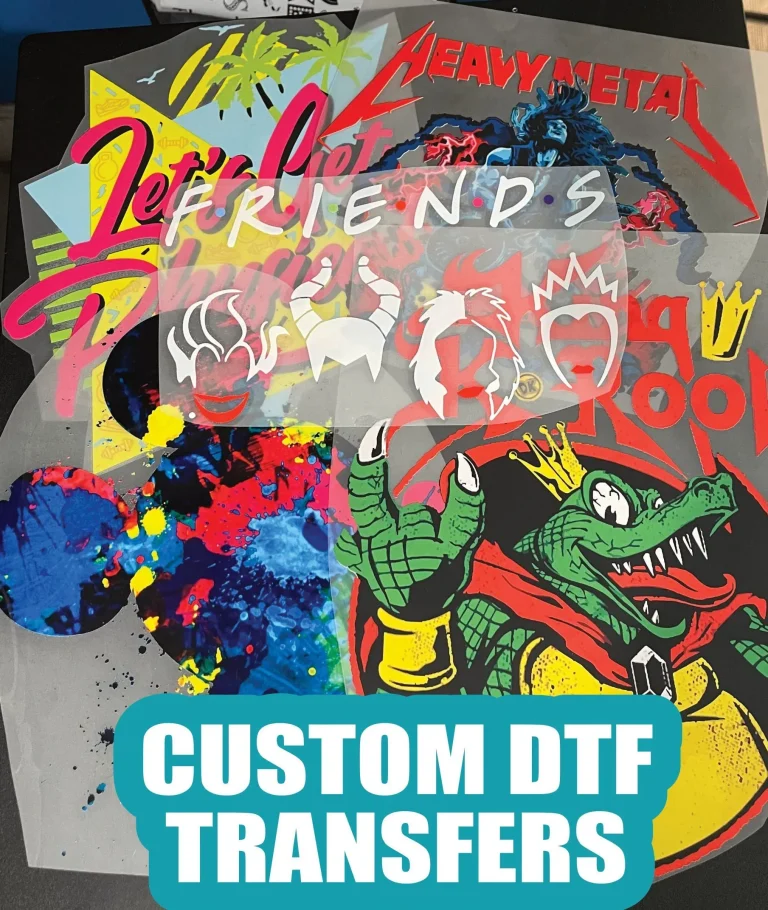

UV DTF printing, or Direct to Film printing, employs advanced technology to create vibrant and long-lasting designs on fabrics. The process begins with the digital printing of high-quality images onto a specialized film, which is then coated with UV-reactive inks. Once the artwork is printed, UV light is used to cure the inks, effectively bonding the design to the film and making it ready for transfer onto fabric. This technique not only enhances color accuracy but also ensures durability, allowing prints to withstand multiple washes without fading.

One of the standout features of UV DTF printing is its ability to produce fine details and intricate designs that are often challenging to achieve with traditional methods. This capability unlocks a new realm of customization for apparel brands, enabling them to cater to consumer preferences for personalized designs. Furthermore, the variety of substrates that UV DTF can print on—including cotton, polyester, and blends—encourages creativity and flexibility in design, ultimately leading to a richer end product.

Sustainable Printing Technology: The Eco-Friendly Edge of UV DTF

As the fashion industry moves towards adopting more sustainable practices, UV DTF printing offers a compelling alternative to conventional methods. This technology utilizes fewer chemicals and generates less waste throughout the printing process compared to traditional screen printing. By minimizing environmental impact, brands that leverage UV DTF can appeal to the growing demographic of environmentally conscious consumers. This commitment to sustainability not only enhances brand image but also helps navigate the complexities of green certifications that consumers increasingly look for.

Additionally, the energy efficiency of UV DTF technology contributes to its sustainability credentials. The immediate curing of inks with UV light significantly reduces energy consumption during production. With facilities striving to lower their carbon footprint, adopting UV DTF technology enables businesses to be part of the solution in combating climate change while still meeting the demands of a competitive market.

Embracing Fashion Customization Through UV DTF

Fashion customization has taken the industry by storm as consumers seek unique, personalized items that reflect their individuality. UV DTF technology enhances this trend, allowing brands to produce one-off designs quickly and affordably. The rapid turnaround time associated with UV DTF means that businesses can respond swiftly to consumer demands and trends, providing the tailored experience that modern shoppers crave. This capability ensures that brands remain competitive while deepening customer loyalty through customized offerings.

Moreover, the ease of modifying designs and colors without the constraints of traditional printing set-ups allows for an unparalleled level of creativity. Brands can test new ideas, cater to niche markets, or personalize items on-demand, all with the same UV DTF setup. This flexibility opens up opportunities for collaborative projects with artists and designers, driving innovation and keeping the brand relevant in a fast-paced industry.

Technological Innovations Driving UV DTF Forward

The evolution of UV DTF technology is closely linked to ongoing innovations within the printing sector. Improvements in ink formulations have dramatically enhanced durability, allowing printed designs to withstand frequent washing and wear without sacrificing color vibrancy. Manufacturers are actively investing in research and development to create inks that adhere better to various fabrics, providing consistent quality across different substrates. Upgrades in machinery also contribute to faster printing speeds and improved detail for finer designs.

These technological developments not only empower existing players in the custom apparel space but also pave the way for new entrants. As UV DTF printing becomes more accessible, a diverse range of businesses—from small boutiques to large fashion houses—can harness its capabilities to bring fresh ideas to life. This democratization of technology fuels creativity within the apparel industry and encourages a culture of innovation that aligns with modern consumer demands.

Market Trends Shaping the Future of Custom Apparel

The custom apparel market is witnessing a profound transformation, with UV DTF printing at the forefront of this evolution. As personalization becomes increasingly prioritized by consumers, brands are compelled to adopt technologies that facilitate rapid and diverse production capabilities. Analysts predict substantial growth in the adoption of UV DTF, driven by the demand for unique designs that meet the specific needs of customers—ranging from individual consumers seeking personalized gifts to brands wanting to engage with their local communities through tailored merchandise.

Furthermore, the rise of digital marketing and e-commerce has amplified the need for quick turnaround times. Consumers now expect fast delivery of customized products, and businesses must adapt to these expectations to stay competitive. Embracing UV DTF technology positions companies to not only meet these demands but also to capitalize on the growing trend of limited edition or seasonal collections that drive urgency and exclusivity in purchasing.

Navigating Challenges in Adopting UV DTF Technology

While the advantages of UV DTF technology are significant, transitioning to this innovative printing method is not without its challenges. One of the primary hurdles is the initial investment required for both equipment and training, which may deter some businesses, especially smaller operations. However, the long-term benefits—including reduced labor and material costs—can offset these initial expenses as companies begin to navigate the learning curve and optimize their processes.

Additionally, creating market awareness around new technologies like UV DTF can be a time-consuming endeavor. Brands must invest in marketing strategies that highlight the unique selling propositions of their prints, such as durability, customization, and sustainability. Establishing a strong brand narrative that educates consumers on the benefits of UV DTF technology can enhance market acceptance and drive consumer demand, ultimately strengthening a brand’s position in the competitive custom apparel landscape.

Frequently Asked Questions

What is UV DTF technology in custom apparel printing?

UV DTF technology, or UV Direct to Film printing, is an advanced printing method that combines ultraviolet (UV) printing techniques with direct-to-film transfer. This technology allows manufacturers to create vibrant, durable prints on various fabrics like cotton and polyester, ensuring high-quality visuals for custom apparel.

How does UV DTF technology contribute to sustainable printing?

UV DTF technology is recognized as a sustainable printing option because it uses fewer chemicals and reduces waste and energy during the printing process. This eco-friendly approach makes it an appealing choice for consumers increasingly seeking sustainable fashion solutions.

What advantages does UV DTF offer for fashion customization?

UV DTF offers several advantages for fashion customization, including high-quality prints with rich colors, speed of production, flexibility in design alterations, and the ability to print on multiple fabric types. This technology enables brands to deliver unique, personalized apparel quickly and efficiently.

How does UV printing enhance the quality of custom apparel?

UV printing, used in UV DTF technology, enhances the quality of custom apparel by providing superior color richness and durability. The UV light instantly cures the ink, preventing fading and wear, which is essential for maintaining the aesthetic appeal of personalized fashion items.

Can UV DTF technology be used for small print runs in custom apparel?

Yes, UV DTF technology is particularly beneficial for small print runs or one-off designs due to its quick production times and reduced setup requirements. This characteristic allows brands to respond to niche markets and changing consumer demands effectively.

What challenges might brands face when adopting UV DTF technology?

Brands transitioning to UV DTF technology may encounter challenges such as high initial investment costs for equipment and training, market awareness and acceptance of the technology, and the need to balance production with fluctuating consumer demands. Addressing these challenges is crucial for successful implementation.

| Aspect | Description |

|---|---|

| Overview | A cutting-edge process combining UV printing and film transfer, producing vibrant and durable graphics. |

| Quality and Versatility | Prints on various fabrics, delivering superior quality and longevity. |

| Speed and Efficiency | Streamlined production for rapid turnaround, ideal for small orders. |

| Sustainability | Eco-friendly alternative that reduces chemicals, waste, and energy consumption. |

| Technological Innovations | Continuous improvement in ink and machinery technologies for better durability. |

| Benefits | Reduced waste, cost-effective, enhanced flexibility for design adjustments. |

| Challenges | Initial investment costs, market awareness, and supply-demand balance. |

Summary

UV DTF technology is revolutionizing the world of custom apparel by merging quality, speed, and sustainability into one innovative solution. As fashion evolves, brands are increasingly drawn towards customization options, and UV DTF captures this trend by allowing for high-quality prints on a diverse range of fabrics. This technology’s ability to facilitate rapid production and minimize environmental impact positions it as a game-changer in the apparel industry, catering to the growing consumer demand for personalization and eco-conscious practices. Moving forward, UV DTF technology will continue to shape the landscape of custom apparel, enabling manufacturers to remain competitive in an ever-evolving market.