UV DTF printing, or UV Direct-to-Film printing, is revolutionizing the textile industry by merging cutting-edge technology with eco-friendly practices. This innovative technique utilizes ultraviolet light to cure inks onto film, creating vibrant prints that can be transferred onto various fabrics, from cotton to synthetics. As the demand for sustainable textiles and custom apparel printing rises, UV DTF printing is quickly becoming the preferred solution for designers seeking both quality and efficiency. Utilizing this remarkable textile printing technology not only enhances design possibilities but also aligns with the growing accessibility of digital fabric printing solutions that minimize environmental impact. In this blog post, we will explore the transformative effects of UV DTF printing on the textile landscape, focusing on its advantages, applications, and why it’s capturing the industry’s attention.

Also known as ultraviolet Direct-to-Film printing, this advanced method has emerged as a game-changer for the textile sector, meeting the increasing demand for both customization and sustainability. With its state-of-the-art curing process, this printing technique ensures high-quality images and robust durability that traditional methods often struggle to achieve. As a significant player in the realm of digital fabric printing, UV DTF printing not only promotes vibrant colors but also reflects the values that consumers are looking for in eco-friendly printing solutions. By embracing this innovative approach, brands are not only enhancing their product offerings but also contributing to the development of sustainable textiles in a competitive market. This exploration of ultraviolet DTF printing will highlight the myriad ways it’s reshaping the fashion and textile industries.

The Emergence of UV DTF Printing Technology

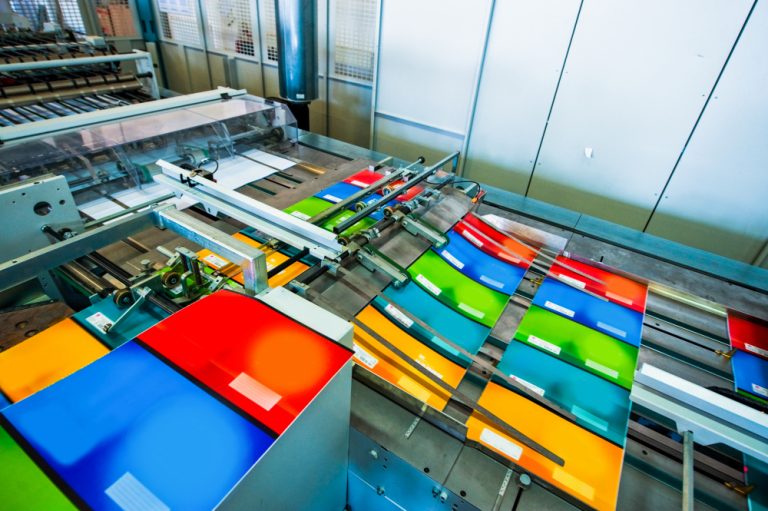

UV Direct-to-Film (DTF) printing has emerged as a revolutionary technology within the textile printing sector, showcasing its capacity to effectively combine quality with innovation. The method employs UV light to cure inks onto a specially designed film, allowing for vivid colors and intricate designs to be transferred seamlessly to a variety of fabrics. This flexibility is drawing attention from both established textile manufacturers and budding designers alike, as they seek modern solutions to cater to the increasingly discerning consumer market.

Beyond its captivating aesthetics, UV DTF printing is also pioneering a wave of efficiency that challenges traditional methods. By allowing for faster curing times and minimal material waste, it offers an appealing alternative for brands aiming to increase productivity while reducing their ecological footprint. This commitment to sustainability is vital in today’s market, where eco-conscious consumerism is on the rise, propelling innovations like UV DTF printing into the forefront of textile technology.

Benefits of Eco-Friendly Printing Solutions

In a world increasingly focused on sustainability, the textile industry has been under significant pressure to adopt more eco-friendly practices. UV DTF printing stands out in this arena, utilizing environmentally responsible inks that significantly reduce harmful emissions compared to conventional printing methods. As consumers grow more environmentally conscious, solutions like UV DTF printing not only fulfill aesthetic needs but also align with a broader commitment to sustainable textiles.

Moreover, the ability of UV DTF printing to reduce fabric waste through better efficiency means that companies investing in this technology can significantly lessen their environmental impact. The shift toward eco-friendly printing solutions not only helps companies comply with emerging regulations but also resonates deeply with customers who prioritize brands with sustainable practices, creating a win-win scenario for both businesses and the planet.

Digital Fabric Printing: How It Shakes Up the Industry

Digital fabric printing methods like UV DTF are transforming traditional textile production paradigms. Unlike traditional printing techniques that can be cumbersome and lengthy, UV DTF allows for short runs without sacrificing quality or increasing costs. This adaptability encourages a creative renaissance among designers as they leverage digital printing’s capabilities to experiment with more intricate designs and vibrant patterns that appeal to modern consumers.

The benefits extend well beyond just creative potential; digital fabric printing also ensures that orders can be customized to meet specific client needs without the extensive setup times associated with traditional methods. This agility aligns perfectly with consumer expectations in a fast-paced market, further establishing UV DTF printing as a preferred solution for custom apparel printing, promotional materials, and a variety of fashion applications.

Custom Apparel Printing: Revolutionizing Fashion

Custom apparel printing has become an integral part of today’s fashion landscape, and UV DTF printing is leading this transformation. The technology allows businesses to create unique garment designs tailored to individual consumer preferences, something that is increasingly in demand in a world of fast fashion. Designers can push the boundaries of their creativity, showcasing art that resonates with specific target demographics.

By offering high-quality customization options, UV DTF printing helps brands differentiate themselves in a crowded market. The ability to produce small batches or even one-of-a-kind pieces without sacrificing print quality or durability means that businesses can cater to niche markets with ease, build customer loyalty, and ultimately drive sales. This shift not only enables designers to express themselves more freely but also creates an avenue for consumers to engage with fashion on a personal level.

Versatility and Applications of UV DTF Printing

UV DTF printing’s versatility makes it suitable for a variety of applications across different sectors. From fashion and apparel to promotional items and interior design, the technology adapts seamlessly to various substrates and materials. This broad applicability enables companies to broaden their offerings, integrating custom designs into multiple product lines—from T-shirts and bags to home textiles like curtains and cushions.

Moreover, this capability encourages collaboration between artists and brands, as UV DTF printing empowers its users to bring intricate designs to life on diverse textiles. As the demand for personalized products continues to grow, this technology captures the essence of modern consumer preferences, allowing for creativity without limits. The future of UV DTF printing holds exciting prospects for industries seeking to redefine traditional boundaries.

The Future of Sustainable Textiles with UV DTF Printing

With consumers becoming more conscious of their environmental impact, the future of textiles will likely be shaped by innovations like UV DTF printing that prioritize sustainability. The technology not only reduces waste during production but also utilizes eco-friendly inks that eliminate toxic substances and harmful emissions, thus mitigating pollution. As awareness around sustainable textiles continues to rise, consumers are likely to favor brands that are making strides in ethical production.

Looking ahead, UV DTF printing stands to play a significant role in the evolution of environmentally responsible textile manufacturing. By integrating advanced technology with sustainable practices, manufacturers can meet the growing consumer appetite for guilt-free consumption in fashion. This future, focused on sustainability, embodies a collective commitment to changing how we create, consume, and appreciate textiles on a global scale.

Frequently Asked Questions

What is the process of UV DTF Printing in textile applications?

UV DTF Printing, or Direct-to-Film printing, involves printing UV-curable inks onto a special film, which is then cured using UV light. This rapid curing allows the inks to bond effectively with a variety of textiles, including cotton and polyester, providing vibrant and durable prints suitable for custom apparel printing.

How does UV DTF Printing support eco-friendly printing solutions?

UV DTF Printing supports eco-friendly printing solutions by using inks that are less harmful to the environment compared to traditional screen printing methods. This technology reduces waste and allows for more efficient fabric utilization, aligning with the industry’s shift towards sustainable textiles.

What are the advantages of using UV DTF Printing for custom apparel printing?

The advantages of UV DTF Printing for custom apparel printing include vibrant color reproduction, intricate design capabilities, and high durability. The fast curing process enhances efficiency, making it ideal for both high-volume and bespoke orders in the textile industry.

Can UV DTF Printing be used on various types of textiles?

Yes, UV DTF Printing can be used on a wide range of textiles including cotton, polyester, and blended fabrics. This versatility allows designers to create custom prints for different applications, from fashion apparel to promotional materials.

Why is UV DTF Printing considered a game-changer for digital fabric printing?

UV DTF Printing is considered a game-changer for digital fabric printing due to its ability to produce high-quality prints with exceptional detail and color vibrancy. The technology also offers faster turnaround times and reduced fabric waste, making it a preferred choice for modern textile production.

What trends are driving the adoption of UV DTF Printing in the textile industry?

Trends driving the adoption of UV DTF Printing include the consumer demand for customized products and sustainable practices in manufacturing. As businesses seek to innovate and remain competitive, integrating UV DTF Printing into their processes has become increasingly essential for meeting these demands.

| Key Points | Description |

|---|---|

| What is UV DTF Printing? | UR Direct-to-Film printing is a modern method that uses UV light to cure inks on a special film for printing on various textiles. |

| Advantages | Vibrant colors, eco-friendly, speed, versatility, quality, cost-effectiveness, and industry adoption are key benefits. |

| Applications | Applicable to T-shirts, promotional materials, and various fabrics, enhancing creative possibilities. |

| Sustainability Impact | Aligns with sustainable practices, reduces waste compared to traditional methods and harmful inks. |

| Future Trends | As consumer demand shifts towards customization and eco-friendliness, UV DTF printing’s relevance in the industry grows. |

Summary

UV DTF Printing is a groundbreaking technology that is reshaping the landscape of textile manufacturing. This innovative method combines speed, vibrancy, and eco-friendliness, offering an alternative to traditional printing techniques. Users benefit from high-quality prints that are both durable and visually striking, making it ideal for fashionable apparel and promotional textiles. As sustainability becomes increasingly important in consumer decisions, UV DTF Printing stands out as a leading solution that balances creative expression with environmental responsibility. The textile industry is on the brink of a transformation, with UV DTF printing paving the way for a future brimming with creative possibilities.