In an ever-growing world of custom apparel printing, UV DTF printing is rapidly gaining recognition as a game-changing technology. This innovative method offers vibrant and durable prints on a wide array of materials, setting a new standard for digital printing technology. Businesses and consumers alike are drawn to UV DTF printing not only for its striking results but also for its commitment to sustainable printing solutions. By harnessing the advantages of UV printing, companies can provide personalized clothing that stands out while minimizing environmental impact. As we delve deeper into the realm of UV DTF printing, we will uncover its remarkable benefits and transformative potential in the apparel industry.

The realm of Direct to Film printing, specifically via ultraviolet processes, is increasingly becoming a pivotal element in the domain of apparel customization. Often referred to interchangeably with UV printing advantages, this technique stands out due to its ability to produce high-quality and long-lasting designs on various substrates. In an age where sustainable alternatives are paramount, digital printing technology like this represents a significant leap toward eco-friendly production methods. Furthermore, the demand for unique and personalized clothing options has never been higher, making methods such as UV DTF essential for businesses looking to thrive in a competitive market. This exploration will reveal the intricacies and advantages of this cutting-edge printing solution.

The Evolution of Custom Apparel Printing

Custom apparel printing has dramatically evolved over the years, transitioning from traditional screen printing to more sophisticated digital technologies. Today, methods like UV DTF printing are leading the charge in this evolution. This innovative technology harnesses the power of ultraviolet light to cure printed inks instantly, paving the way for vibrant colors and precise details that surpass older printing techniques. As demand for personalized clothing and unique designs surges, advanced technologies are becoming essential for providing consumers with exceptional quality.

The move towards digital printing solutions in the apparel industry allows for greater customization and quick turnarounds on orders. In this competitive landscape, businesses that adopt UV DTF printing will likely outpace their competitors by offering high-quality goods with unmatched clarity and color retention, particularly when it comes to intricate graphics and logos. As technology continues to evolve, the custom apparel market is becoming an exciting arena for both consumers and brands eager to express individual style and creativity.

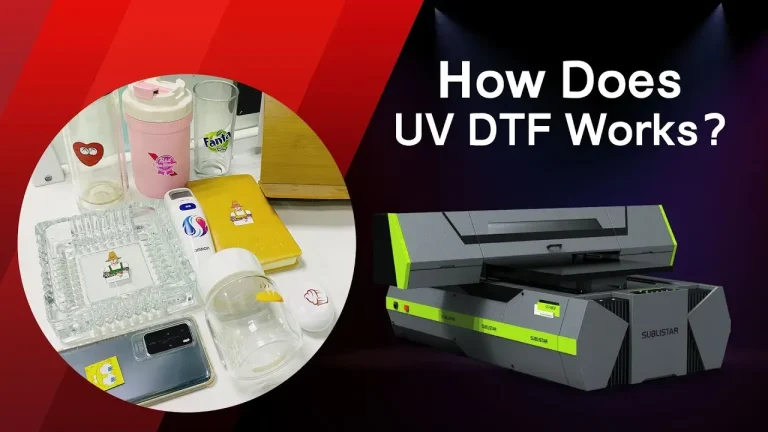

How UV DTF Printing Works

UV DTF printing utilizes a specialized printing process that combines digital printing technology with ultraviolet light curing. When inks are printed onto a film, they are exposed to UV light, which immediately solidifies the ink, resulting in a durable and vibrant print. This process not only speeds up production but also eliminates the need for lengthy drying times associated with traditional printing methods. Moreover, the precision of UV DTF technology allows for fine details and gradients to be reproduced flawlessly on a wide range of substrates.

Furthermore, UV DTF printing showcases its versatility by effectively printing on various surfaces beyond fabrics, including plastics, metals, and even wood. This flexibility opens new avenues for businesses to explore innovative product offerings, capitalizing on the growing trend for custom products. As more companies embrace this efficient and modern printing method, the ability to create personalized clothing and accessories becomes significantly enhanced, allowing for tailored experiences that resonate with diverse consumer preferences.

Environmental Benefits of UV DTF Printing

In an era where sustainability is paramount, UV DTF printing stands out for its environmentally friendly characteristics. This printing technology often employs eco-conscious inks that release fewer volatile organic compounds (VOCs) compared to traditional printing methods. By minimizing waste and energy consumption, UV DTF not only supports businesses in reducing their environmental footprint but also appeals to a growing base of eco-aware consumers seeking sustainable options in their apparel purchases.

As customers grow increasingly mindful of their choices, businesses that prioritize sustainable printing solutions like UV DTF will likely gain a competitive edge. This alignment with consumer values enhances brand loyalty and satisfaction, as customers actively seek out companies that demonstrate responsible environmental practices. By adopting UV DTF printing technology, brands are not only investing in advanced capabilities but also reinforcing their commitment to a healthier planet.

Cost Effectiveness in UV DTF Technology

Cost efficiency is a crucial aspect of the custom apparel printing industry, and UV DTF printing excels particularly in this regard. The technology’s ability to minimize ink waste through precision application and reduce production time translates to significant savings for businesses. As turnaround times diminish with UV DTF, companies can respond swiftly to consumer demands, thereby increasing their profitability without compromising on quality.

Furthermore, as companies streamline their production processes with UV DTF, they may find that their operational costs decrease over time. This cost-effectiveness allows businesses to allocate resources more strategically, whether investing in innovative designs or enhancing marketing efforts. As a result, adopting UV DTF printing technology not only offers immediate financial benefits but also ensures long-term viability in an ever-changing marketplace.

Customization Trends in Apparel Printing

Today’s consumers are increasingly driven by a desire for unique and personalized products. Customization trends have overtaken the apparel market as brands strive to provide more tailored experiences for their customers. UV DTF printing accommodates these trends remarkably well, allowing for intricate designs, vibrant colors, and personalized touches that resonate with consumer preferences.

As businesses leverage UV DTF printing to create custom apparel, they are better positioned to capitalize on this growing demand for individualized products. Supporting consumer interests in unique clothing items solidifies brand loyalty while encouraging a connection between the consumer and the brand. This technology provides the perfect platform to explore new creative avenues, ultimately driving innovation in the fashion industry.

Future Prospects of UV DTF Printing

The outlook for UV DTF printing is incredibly promising as more businesses recognize the advantages it offers. Market trends indicate a significant rise in demand for UV printing technology, especially in the custom apparel sector, where personalization is becoming a standard expectation rather than a luxury. This growth reflects a fundamental shift in consumer behavior, embracing uniqueness and tailored styles.

In the coming years, we can anticipate that advancements in digital printing technology, alongside the rising demand for sustainable printing solutions, will further enhance the capabilities of UV DTF printing. As businesses continue to innovate and invest in high-quality, efficient printing methods, those utilizing UV DTF will likely experience a competitive advantage, solidifying their place in the evolving landscape of custom apparel.

Frequently Asked Questions

What is UV DTF printing and how does it work?

UV DTF printing, or UV Direct to Film printing, utilizes ultraviolet light to cure inks immediately during the printing process. This ensures vibrant, durable prints on various substrates, making it a cutting-edge method in the custom apparel printing industry.

What are the advantages of using UV printing for custom apparel?

UV printing advantages include immediate curing of inks for high-quality, durable prints, the ability to print on multiple materials, reduced environmental impact with eco-friendly inks, and cost efficiency due to less waste and faster production times.

How does UV DTF printing support sustainable printing solutions?

UV DTF printing supports sustainable printing solutions by using eco-friendly inks with lower emissions of volatile organic compounds (VOCs). This makes it a more environmentally responsible option compared to many traditional printing methods.

Can UV DTF printing be used for personalized clothing?

Yes, UV DTF printing is ideal for personalized clothing as it allows for intricate designs and high-quality graphics. This technology meets consumer demand for unique and customized apparel, enhancing customer satisfaction.

What is the versatility of UV DTF printing in different materials?

The versatility of UV DTF printing allows it to print on a diverse range of materials, including fabrics, plastics, metals, and wood. This capability enables businesses to expand their product offerings beyond traditional fabrics.

Why is UV DTF printing considered cost-efficient for businesses?

UV DTF printing is cost-efficient because it minimizes ink waste and accelerates production times. Faster turnaround times and effective ink utilization contribute to overall savings, making it a financially viable investment for custom apparel businesses.

| Key Point | Description |

|---|---|

| Introduction | UV DTF printing is transforming custom apparel printing with vibrant, durable prints. |

| Technology | Uses UV light to quickly cure inks, enhancing quality and production speed. |

| Versatility | Can print on various materials, including plastics, metals, and wood. |

| Environmentally Friendly | Utilizes eco-friendly inks that minimize VOC emissions. |

| Cost Efficiency | Reduces waste and improves turnaround times, leading to cost savings. |

| Customization Trends | Supports intricate designs and high-quality graphics for personalized products. |

| Market Growth | Custom apparel market demand is rising, benefiting UV DTF technology. |

Summary

UV DTF printing is revolutionizing the landscape of custom apparel with its innovative technology and unmatched versatility. As it combines efficiency with eco-friendly practices, UV DTF printing provides businesses the advantage of producing high-quality, durable prints on a variety of materials while minimizing environmental impact. This advanced printing solution not only caters to the growing consumer demand for personalized products but also significantly reduces operational costs, proving to be a lucrative investment for companies in the printing sector. Embracing UV DTF technology is essential for businesses looking to thrive in a competitive market driven by customization and sustainability.