In the realm of modern printing solutions, UV DTF printing has emerged as a game-changing technology that offers high-quality prints with exceptional versatility. This innovative method combines the robustness of UV printing technology with the benefits of Direct to Film (DTF) techniques, resulting in vibrant and durable prints that can meet diverse consumer needs. Whether it’s textiles, metals, or rigid plastics, UV DTF can produce stunning visuals that captivate audiences. As businesses strive to elevate their product offerings, utilizing UV DTF ensures that they remain competitive in a saturated market. In this exploration of UV DTF printing, we will delve into its advantages, applications, and the latest industry trends impacting the world of high-quality product prints.

Often referred to as Direct to Film UV printing, this advanced printing technique stands out due to its ability to deliver exceptional results across a broad range of materials. By utilizing ultraviolet curing inks, this versatile printing method ensures that designs maintain their crispness and vibrancy, setting a higher standard for product prints. With the capability to produce durable prints that withstand various environmental challenges, businesses can leverage this technology to enhance their offerings. As the landscape of printing continues to evolve, alternative methods like DTF printing are also gaining traction, yet none quite match the durability and quality provided by UV DTF technology.

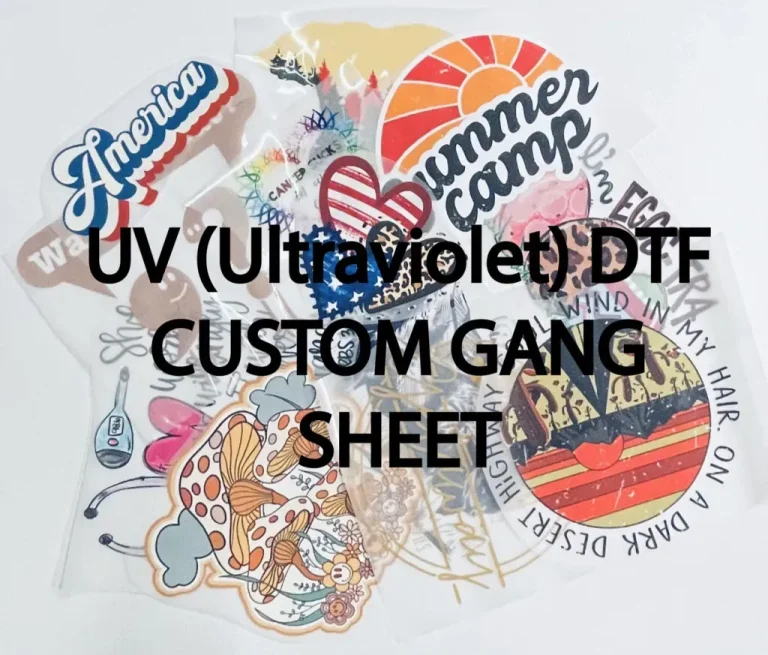

Understanding UV DTF Printing Technology

UV DTF printing, abbreviated as Ultraviolet Direct to Film printing, is revolutionizing the way businesses approach high-quality prints. This innovative technique leverages the principles of UV printing technology, which employs ultraviolet light to cure the inks as they are applied to the substrate, resulting in rich and vibrant colors. Unlike traditional printing methods, UV DTF can print on a vast range of materials, including textiles, metals, glass, and even unconventional surfaces such as wood or ceramics. This characteristic makes UV DTF an invaluable asset for companies looking to diversify their product offerings.

The rapid advancements in UV DTF technology have positioned it as a versatile printing method that caters to a plethora of industries. Whether it’s for promotional items, apparel, or unique home decor, the ability to produce detailed designs with striking color contrast sets UV DTF apart from other traditional methods. The prints produced are not only eye-catching but also exhibit commendable durability, ensuring that products maintain their visual appeal over time.

Frequently Asked Questions

What are the advantages of UV DTF printing for high-quality prints?

UV DTF printing offers numerous advantages, including versatility across various substrates, vivid colors, exceptional durability, and eco-friendly materials. This versatile printing method allows for high-quality prints on textiles, glass, and metals, making it an ideal choice for businesses looking to deliver standout products.

How does UV DTF printing differ from traditional DTF printing?

UV DTF printing utilizes UV-cured inks to achieve superior print quality, whereas traditional DTF printing typically relies on heat transfer processes. This modern technique provides more durability and vibrant colors, enabling businesses to create high-quality prints that last without fading or cracking.

Can UV DTF printing be used on various materials?

Yes, UV DTF printing is known for its versatility, allowing prints on a wide range of materials including cotton, ceramics, acrylics, and metals. This diverse printing capability makes it a valuable option for businesses looking to expand their product offerings with high-quality prints on different substrates.

What is the durability of prints produced by UV DTF technology?

UV DTF prints are exceptionally durable, resistant to scratches, fading, and moisture. This durability ensures that high-quality prints retain their visual appeal and withstand wear and tear over time, making them suitable for products exposed to frequent handling or outdoor conditions.

Is UV DTF printing an eco-friendly option?

UV DTF printing is considered more eco-friendly compared to traditional printing methods as it uses UV-curable inks with lower volatile organic compounds (VOCs). Businesses looking for sustainable printing solutions can benefit from adopting UV DTF technology.

What recent innovations are being seen in UV DTF printing technology?

Recent innovations in UV DTF printing include advancements in printer technology that enhance production speed and quality. For instance, new models like the eufyMake E1 allow for high-definition prints with added textures, showcasing the evolution and accessibility of UV DTF printing for businesses and creators alike.

| Key Points | Details |

|---|---|

| What is UV DTF Printing? | A cutting-edge technique using UV-cured inks to produce high-definition prints on various surfaces. |

| Versatility Across Substrates | Can print on diverse materials like textiles, metal, glass, and rigid plastics, enhancing product offerings. |

| Vivid Colors and Superior Textures | Delivers stunning colors and textures, with printers like the eufyMake E1 showcasing advanced capabilities. |

| Exceptional Durability | Resistant to scratches, fading, and moisture, ensuring long-lasting quality. |

| Eco-Friendly Printing Solutions | Utilizes UV-cured inks, which emit lower levels of VOCs when compared to traditional inks. |

| Increased Speed and Efficiency | Advancements have enhanced production capacity, allowing for quicker turnaround times. |

| Current Trends in UV DTF | Investments in advanced technology and innovative product development are shaping the future of UV DTF. |

Summary

UV DTF printing is an innovative solution revolutionizing the matter of high-quality product prints. Its integration of UV technology with DTF methods offers businesses unmatched versatility, providing the ability to print on a variety of surfaces with stunning color and texture. The exceptional durability of UV DTF prints makes them ideal for products exposed to frequent handling, ensuring longevity and aesthetic appeal. With eco-friendly practices and increased efficiency in production times, UV DTF stands out as the go-to option in today’s competitive market. As trends in technology continue to evolve, UV DTF printing allows for endless creativity and is paving the way for remarkable advancements in the printing industry.