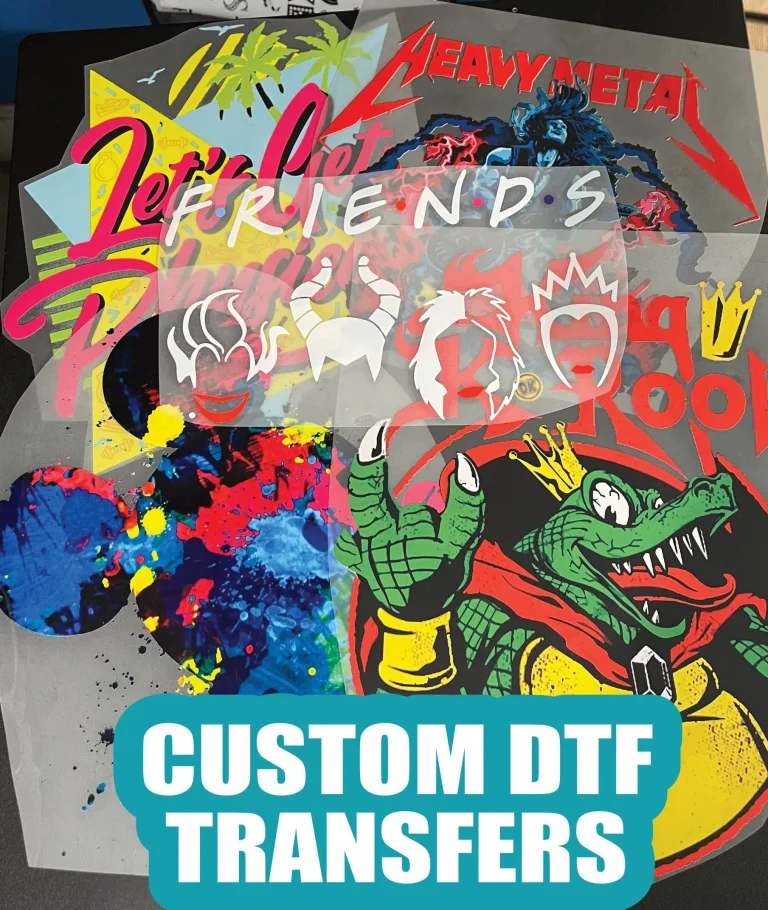

UV DTF printing, a cutting-edge technique that merges ultraviolet printing technology with Direct-to-Film printing, is transforming the landscape of modern printing. As industry leaders like Mimaki and eufyMake unveil their latest innovations, the advantages of UV DTF become increasingly apparent to artists, manufacturers, and hobbyists alike. This revolutionary method excels in producing vibrant and durable prints on a diverse array of substrates, expanding the capabilities of traditional printing. With UV inks that cure rapidly under ultraviolet light, users enjoy improved color vibrancy and enhanced print quality without sacrificing speed. As we explore the mechanics of UV DTF printing, it’s clear that this technology is not just a trend; it represents the future of printing innovation.

In the realm of advanced printing methods, UV Direct-to-Film printing has emerged as a frontrunner, utilizing UV light to cure inks applied on specially coated film. This novel approach, often referred to as UV printing technology, harnesses the prowess of Direct-to-Film techniques to create stunning visual outputs on various materials. The Mimaki UV DTF printer and eufyMake’s latest innovations exemplify the evolution of this sector, showcasing the flexibility and durability that modern projects demand. As the advantages of UV DTF printing continue to be recognized, users are finding new avenues for creativity and personalization. With the technology rapidly advancing, it’s an ideal time to delve into how these methods can redefine the printing landscape.

The Future of UV DTF Printing Technology

As the market for printing technology continues to expand, UV DTF printing stands out due to its ability to adapt to new demands. The future of UV DTF printing is set to be even more innovative, thanks in part to advancements in UV printing technology. Manufacturers are tirelessly working on creating printers that provide higher resolution and improved color accuracy. Furthermore, the evolution of inks used in UV DTF printing is likely to enhance durability and expand the range of materials that can be effectively printed on.

With companies like Mimaki leading the charge in pushing the boundaries of UV DTF printing technology, we can expect a series of breakthroughs that will revolutionize how businesses and artists approach their printing needs. Innovations such as dual ink applications or faster curing processes will likely emerge, setting new industry standards and streamlining production workflows.

Understanding the Advantages of UV DTF Printing

One of the major advantages of UV DTF printing is its unmatched versatility. This technique enables users to produce high-quality prints on various substrates including plastics, metal, textiles, and more, making it an ideal choice for small businesses looking to diversify their product offerings. Additionally, the durability of UV-cured prints cannot be overstated; these prints resist fading, cracking, and peeling, ensuring that they maintain their visual appeal for an extended period. This durability translates to lower costs for businesses, as they replace printed products less often.

Aside from durability and versatility, UV DTF printing is recognized for its speed and efficiency. The ability to print quickly without sacrificing quality allows businesses to meet tight deadlines and respond promptly to customer demands. In an industry where turnaround time can be crucial, the advantages of UV DTF printing create a competitive edge for those who adopt this technology.

Mimaki’s Contribution to UV DTF Printing

Mimaki has made significant strides in advancing UV DTF printing with its latest innovations tailored to the needs of creative professionals. The launch of their new UV DTF printer marks a turning point for businesses focused on producing custom stickers and labels. This product not only simplifies the printing process but also enhances the quality and appeal of the final output, showcasing the capabilities of UV DTF technology.

By incorporating various ink and varnish options, Mimaki caters to a broad spectrum of creative industries, allowing for bespoke applications that were not possible with traditional printing methods. This versatility in functionality highlights not only Mimaki’s technical advancements but also the potential for UV DTF printing to open new markets for businesses eager to innovate in their product offerings.

eufyMake’s Innovative Features in UV DTF Printing

Anker’s eufyMake has introduced a groundbreaking UV DTF printer that emphasizes the importance of user-friendly design without compromising on functionality. The eufyMake UV Printer E1 is especially notable for its ability to print complex, 3D textured patterns that expand the creative horizons for users. This technology supports artists and small businesses looking to add a unique touch to their products.

By focusing on high-resolution printing capabilities, eufyMake is making strides in the competitive landscape of UV DTF printing. Such innovations create opportunities for artists to produce detailed and engaging prints, encouraging creativity while also addressing practical demands in terms of user experience and design implementation.

Compact UV Printers: Revolutionizing Accessibility

The recent trend towards compact UV printers is making UV DTF printing more accessible to hobbyists and small creative businesses. These printers are designed to be user-friendly and take up less space while still offering powerful printing capabilities. Artists no longer need expansive print environments to engage in high-quality printing projects; instead, they can leverage compact technology to produce stunning prints from the comfort of their homes or small studios.

What’s significant about these compact UV printers is their ability to deliver high-definition results even on challenging materials like textiles, metal, and leather. This blend of portability and performance not only provides creatives with the tools they need to experiment but also fosters a growing community of hobbyists who can confidently enter the world of professional-grade printing.

The Role of UV DTF in Personalization Trends

UV DTF printing is at the forefront of a significant trend towards personalization in consumer goods. As more customers seek unique and customized products, the adaptability of UV DTF technology allows artists and businesses to cater to this demand effectively. The ability to produce intricate designs that reflect individual preferences is paving the way for a new era of consumer engagement.

With the rise of online platforms that facilitate personalized product offerings, UV DTF printing is in a prime position to capitalize on this trend. Businesses leveraging UV DTF technology can effectively tap into niche markets and provide customers with distinct, colorful creations that stand out in the marketplace.

Frequently Asked Questions

What is UV DTF printing and how does it work?

UV DTF printing, or UV Direct-to-Film printing, combines ultraviolet light technology with direct-to-film methods to produce high-resolution prints on various substrates. In this process, special inks are applied to a printable film that is cured using UV light, ensuring vibrant colors and durable prints that can adhere to materials like fabric, wood, and ceramics.

What are the advantages of UV DTF printing over traditional printing methods?

The advantages of UV DTF printing include its versatility, allowing printing on multiple materials; durability, thanks to the UV-curing process that enhances ink adherence; high efficiency in production speed; low waste generation; and the ability to produce exceptionally vibrant and intricate colors, making it a favored choice in modern printing.

How does the Mimaki UV DTF printer enhance sticker production?

The Mimaki UV DTF printer offers innovative capabilities specifically designed for sticker production, simplifying the process of creating unique stickers suitable for diverse surfaces. This new technology emphasizes advanced ink and varnish options, enabling better customization and application in creative markets.

What unique features does the eufyMake UV printer provide for users?

The eufyMake UV printer, particularly the E1 model, includes the ability to print high-resolution, 3D-textured designs on surfaces such as ceramics and fabric. This feature enhances user creativity by allowing for intricate, tactile prints that can benefit both small businesses and hobbyist projects.

Can UV DTF printing be used for large format projects?

Yes, UV DTF printing is adaptable for large format projects, and companies are investing in expanding their capabilities. With new large-format printers being introduced, businesses can accommodate bigger printing needs while maintaining quality and faster production times.

What types of materials can be printed using UV DTF technology?

UV DTF printing is highly versatile and can be used on a wide range of materials, including fabrics, wood, metal, ceramics, and more. This adaptability allows artists and manufacturers to explore various applications and product designs, enhancing their creative possibilities.

| Key Points | Details |

|---|---|

| Introduction | UV DTF printing revolutionizes printing technology by integrating UV light with direct-to-film techniques, offering diverse benefits for artists and businesses. |

| What is UV DTF Printing? | A printing method using UV technology to achieve vibrant prints on various substrates, ensuring durability and high-resolution results. |

| Innovations | Mimaki’s new printer focused on stickers; eufyMake’s 3D-texture UV Printer E1; compact printers for detailed textures. |

| Advantages | Versatility, durability, efficiency, low waste, and vibrant colors are key benefits of UV DTF printing. |

| Market Growth | Companies like EazyDTF are expanding capacity with large-format printers to meet growing demand across projects. |

Summary

UV DTF Printing is at the forefront of modern printing technology, redefining creativity and personalization in the printing industry. By combining innovative techniques and advanced machinery, UV DTF printing allows for exceptional color vibrancy and durability across various substrates. The contributions from leading companies like Mimaki and eufyMake demonstrate the industry’s commitment to enhancing printing capabilities, making it a favored choice for both professionals and hobbyists. As the market for UV DTF printing continues to grow with significant expansions and innovations, it provides unprecedented opportunities for artists and businesses alike to explore their creative visions. With its versatility and efficiency, UV DTF printing is not just a trend but a transformative force in the realm of printing.