UV DTF printing represents a remarkable advancement in modern printing technology, blending the traditional charm of print with innovative techniques. Utilizing ultraviolet light to cure eco-friendly inks, this method produces vibrant and durable prints that can adhere to a variety of surfaces, ranging from textiles to rigid substrates. As businesses venture into the realm of custom printing, understanding the implications of UV DTF printing compared to traditional printing methods, such as screen printing and offset printing, becomes paramount. Not only does this technique ensure high print quality and detail, but it also addresses environmental concerns that are increasingly crucial in today’s market. By choosing UV DTF printing, businesses can embrace both modernity and sustainability, setting themselves apart in a competitive landscape.

Direct to Film (DTF) printing has emerged as a cutting-edge solution in the print industry, combining the efficiency of digital printing with the resilience of traditional methods. Known for its ability to create stunning visuals across a variety of materials, this technique capitalizes on the benefits of eco-friendly inks, making it a great choice for brands focused on sustainability. Unlike conventional processes like screen printing, DTF printing offers versatility in design and substrate compatibility, allowing for a broader range of applications. As we explore the landscape of contemporary printing options, consider how DTF printing stands out in terms of print quality, durability, and overall environmental impact. In a world increasingly driven by innovation, adopting such advanced methods helps businesses remain competitive while prioritizing ecological responsibility.

The Emergence of UV DTF Printing in Modern Businesses

In the contemporary landscape of printing technology, UV DTF printing has emerged as a revolutionary method that integrates cutting-edge technology with practicality. Unlike traditional printing techniques, UV DTF employs ultraviolet light to instantly cure inks on a variety of substrates, resulting in durable and vibrant prints. This method not only caters to a range of materials such as textiles and rigid surfaces but also encourages creative flexibility, allowing businesses to produce intricate designs that stand out in a crowded market.

As more businesses embrace digital transformation, UV DTF printing is becoming increasingly popular due to its efficiency and high-quality output. The shift from traditional methods to UV DTF reflects a growing demand for versatile and eco-friendly printing solutions that do not compromise on detail or durability. With the ability to print on unconventional materials, companies can diversify their offerings, tapping into new markets and catering to unique customer needs.

Benefits of Choosing UV DTF Printing Over Traditional Methods

One of the most significant advantages of UV DTF printing is its exceptional print quality, characterized by vibrant colors that capture even the finest details of a design. This high-resolution capability vastly outstrips most traditional printing methods, making UV DTF an ideal choice for brands looking to make a lasting impression. With advancements in technology, the results from UV DTF printing are not only aesthetically pleasing but also highly durable, ensuring that prints remain intact and true to color over time.

Furthermore, UV DTF printing often utilizes eco-friendly inks that are safer for the environment compared to solvent-based options predominant in traditional printing. These innovative inks do not emit harmful VOCs (volatile organic compounds), positioning UV DTF printing as a responsible choice for businesses committed to sustainability. This commitment to environmentally friendly practices can also enhance a brand’s reputation, appealing to a growing customer base that values eco-conscious production.

Exploring the Versatility of UV DTF Printing

Versatility is another hallmark of UV DTF printing, setting it apart from traditional methods such as screen printing, which are limited by substrate and design constraints. UV DTF can easily print on a wide range of materials including textiles, plastics, metal, glass, and more. This adaptability opens up diverse opportunities for businesses, allowing for the creation of unique promotional items, garments, and custom products tailored to specific customer requests.

Moreover, businesses can leverage this versatility to experiment with creative designs and products that traditional printing might not support. This not only expands the product line but also positions companies to respond more dynamically to market trends and customer demands. By exploring the capabilities of UV DTF printing, businesses can differentiate themselves in a competitive market.

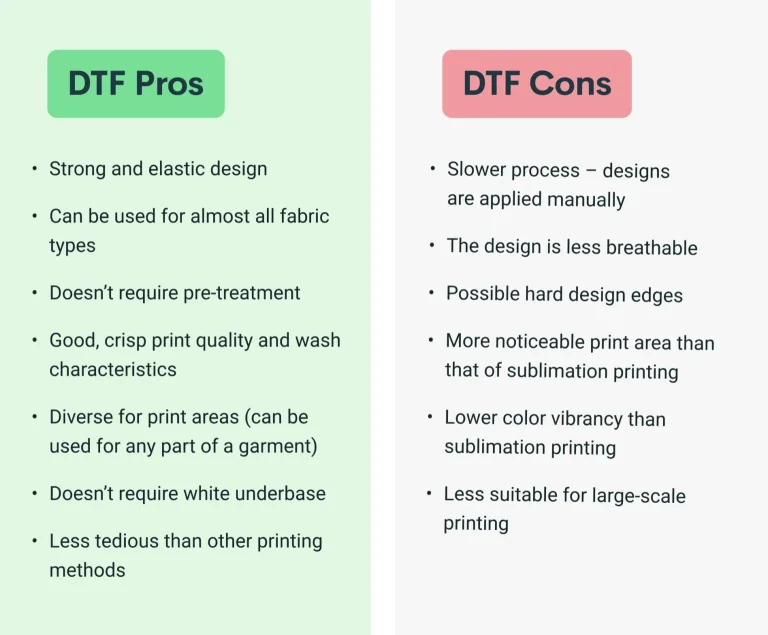

Understanding the Limitations of UV DTF Printing

Despite its advantages, UV DTF printing is not without its challenges. One of the primary concerns is the initial investment required for the specialized equipment and inks. For small businesses or startups, the higher upfront costs may pose a significant barrier compared to traditional printing methods, which typically have lower setup costs. This investment, however, should be weighed against the potential for higher quality output and lower long-term costs, which can ultimately make UV DTF a more lucrative option.

Another limitation involves the technical expertise required to operate UV DTF printers effectively. These machines can be complex and may require specific training to achieve optimal results. For businesses transitioning from traditional printing methods, this learning curve can lead to longer production times while employees adapt to the new technology. However, those who invest in training will likely see significant returns through enhanced print quality and operational efficiency.

Evaluating Traditional Printing Methods: Advantages and Disadvantages

Traditional printing methods like screen printing and offset printing have long been established and are favored for their cost-effectiveness in producing large quantities. One of the primary advantages of these methods is their lower initial cost, making them accessible for small to mid-sized businesses looking to maintain tight budgets while fulfilling bulk orders. Additionally, traditional printing processes are well understood by the industry, ensuring reliability and quality for routine projects.

However, traditional methods come with limitations regarding flexibility and substrate options. They are often not suited for complex, multi-colored designs or the variety of materials that UV DTF printing easily accommodates. This restriction can hinder creativity and the ability to cater to bespoke client requests, pushing businesses to evaluate whether traditional methods can meet their evolving needs.

How Print Quality Differs Between DTF and Traditional Methods

When it comes to print quality, UV DTF printing offers a clear advantage over traditional methods. The ability to create high-resolution images with a wide range of colors ensures that designs are reproduced accurately and with striking detail. This capability is crucial for brands that rely on visual impact to communicate their identity and connect with consumers. With UV DTF printing, businesses can achieve superior sharpness and vibrancy, essential for capturing attention in a visually driven market.

In contrast, traditional printing methods often face challenges with color consistency and detail, particularly in intricate designs. The results can vary based on factors such as substrate type and ink application techniques. While screen printing may work well for simple graphics, it can struggle with more complex images that require gradient color transitions. For businesses seeking precision in their visual communications, UV DTF printing stands out as the more reliable option.

Frequently Asked Questions

What are the advantages of UV DTF printing over traditional printing methods?

UV DTF printing offers numerous advantages compared to traditional printing. It provides high durability against scratches and fading, vibrant colors with intricate details, and allows for printing on a wide variety of materials. Additionally, many UV DTF processes utilize eco-friendly inks, making it a more sustainable choice compared to conventional printing methods.

How does UV DTF printing compare to DTF printing in terms of quality?

UV DTF printing generally provides superior print quality compared to standard DTF printing. This method utilizes UV light to cure inks, resulting in sharper images, more vibrant colors, and better longevity. While both options are effective, UV DTF’s advanced technology enhances the overall print quality.

Is UV DTF printing more eco-friendly than traditional printing methods?

Yes, UV DTF printing is considered more eco-friendly than many traditional printing methods. It often employs eco-friendly inks that are less toxic and harmful to the environment compared to solvent-based inks used in traditional processes. Businesses seeking sustainable options may find UV DTF printing aligns better with their environmental goals.

What materials are best suited for UV DTF printing compared to traditional printing?

UV DTF printing excels in versatility, allowing prints on a wide range of materials, including textiles, plastics, metal, and more. In contrast, traditional printing methods like screen printing often have limitations regarding substrate options, which can restrict design possibilities and application.

What are the main disadvantages of UV DTF printing compared to traditional methods?

The primary disadvantages of UV DTF printing include higher initial costs for equipment and inks, and complex equipment requirements that may not be readily available in all printing shops. These factors can make it more challenging for smaller businesses to adopt this technology compared to more established traditional methods.

Can UV DTF printing produce better color vibrancy than screen printing?

Absolutely. UV DTF printing is renowned for its ability to produce color vibrancy and intricate detail that often surpasses that of screen printing. Thanks to the curing process that utilizes UV light, prints obtained through UV DTF have enhanced color richness and clarity, making them visually striking.

| Key Point | UV DTF Printing | Traditional Printing Methods |

|---|---|---|

| Durability | High durability, resistant to scratches, water, and UV fading. | Lower durability, less resistant to environmental factors. |

| Print Quality | Vibrant colors and high-resolution output for intricate designs. | Reliable quality but limited in color vibrancy and detail. |

| Environmental Impact | Utilizes eco-friendly inks, aligning with sustainable practices. | Often uses less eco-friendly inks, higher environmental footprint. |

| Versatility | Applicable on various materials including textiles and hard substrates. | Limited to certain substrates and designs; less creative flexibility. |

| Initial Costs | Higher initial costs due to specialized equipment and inks. | Lower setup costs, making it accessible for small to mid-sized businesses. |

Summary

UV DTF Printing is a revolutionary method in the realm of printing technology that offers businesses vibrant, durable prints suitable for a multitude of surfaces. This innovative approach not only excels in producing intricate designs with a wide color palette but also champions eco-friendliness by utilizing sustainable inks. Despite its higher initial investment and the need for specialized equipment, the advantages of UV DTF printing can provide significant benefits for businesses aiming to enhance their product durability and aesthetic appeal. As you consider your printing options, weighing the advantages of UV DTF printing against traditional methods will guide you to make informed decisions that align with your production goals.