In the realm of modern printing, **UV DTF printing** stands out as an innovative technique that combines the precision of UV printing technology with the flexibility of Direct to Film printing. This hybrid method allows for high-quality, vibrant designs that are not only stunning but also incredibly durable, making it a popular choice for custom apparel printing and various promotional products. Understanding the UV printing advantages helps businesses and individuals alike tap into the potential of this technology, whether creating customized t-shirts or unique decorative items. This beginner’s guide acts as a comprehensive introduction to the essentials of UV DTF, equipping you with the knowledge to harness its capabilities effectively. Explore the fascinating world of UV DTF printing and discover how you can elevate your creative projects with this cutting-edge approach.

UV Direct to Film printing, often referred to as UV DTF printing, is a state-of-the-art printing solution that bridges the gap between traditional printing techniques and innovative technologies. By applying UV inks onto a specialized film substrate, this method ensures quick curing under ultraviolet light, providing vibrant and long-lasting results. Those venturing into the field of custom apparel and promotional products will find that UV printing technology offers significant advantages, including better durability and adaptability across various materials. This overview serves as a doorway into the intricate process of UV DTF, where artists and entrepreneurs can capitalize on the transformative potential of direct-to-film solutions. Discover everything you need to know, from equipment essentials to practical applications, in this Beginner’s guide to UV DTF.

Understanding the Basics of UV DTF Printing

UV DTF (Direct to Film) printing combines the benefits of UV printing technology with the efficiency of direct film printing. This innovative method involves the application of UV-cured inks directly onto a specially coated film. The process starts by printing vibrant graphics onto the film, which then undergoes a curing process facilitated by ultraviolet light. This immediate curing sets the ink, ensuring that the designs are not only vivid but also long-lasting. The ability to print intricate designs quickly makes UV DTF a popular choice for various applications.

As a beginner, understanding the subtleties of UV DTF printing is essential. The technology operates on the principles of direct film application and UV curing, which allows prints to dry almost instantly. The quick turnaround time is one of the major advantages of using this method for custom projects. With the correct setup, beginners can start creating stunning, high-quality prints, making it an appealing route for those entering the custom printing market.

Advantages of UV DTF Printing Over Traditional Methods

UV DTF printing stands out in the crowded landscape of printing techniques due to its numerous advantages. One of the primary benefits is the durability of the prints produced. Unlike traditional methods, UV-cured inks are resistant to scratches, fading, and environmental wear, making them suitable for products that will be exposed to harsh conditions. This attribute is particularly valuable for businesses aiming to deliver high-quality and long-lasting products.

Moreover, UV DTF printing is incredibly versatile. It can adhere to a variety of substrates, ranging from fabrics like cotton and polyester to non-fabric surfaces, such as wood, metal, and plastic. This wide-ranging compatibility opens new opportunities for custom apparel printing and promotional products. Businesses can leverage this technology to create unique designs on different materials, thus expanding their product offerings.

Applications of UV DTF Printing in Various Industries

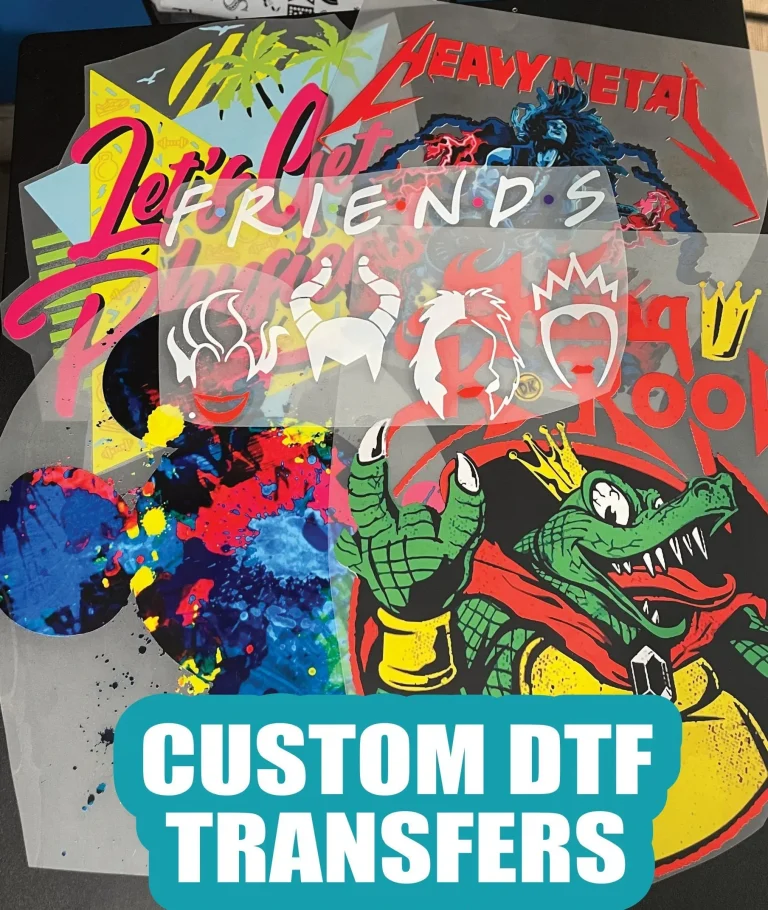

The applications for UV DTF printing are diverse, penetrating several industries such as fashion, promotional items, and interior decoration. In the realm of custom apparel, UV DTF printing allows for detailed and colorful designs on garments, ensuring that brands can stand out with eye-catching graphics. The fashion industry benefits from the ability to create both short runs and mass-produced items with high-quality prints that maintain their integrity through regular use.

Additionally, UV DTF printing has made significant inroads in the production of promotional products. Items such as custom bags, mugs, and stationery can be printed using this technology, ensuring that businesses deliver eye-catching merchandise that reflects their brand identity. The flexibility and high-quality outcomes of UV DTF printing contribute to its growing popularity in promotional campaigns, enhancing how brands connect with their audiences.

Exploring Eco-Friendly Benefits of UV DTF Printing

One of the standout features of UV DTF printing is its environmentally friendly approach. Traditional printing methods often rely on harmful solvents and inks, but UV inks emit significantly fewer volatile organic compounds (VOCs). This makes UV DTF printing a more sustainable choice for businesses that prioritize eco-conscious practices. Companies are increasingly seeking solutions that minimize their environmental footprint, and UV DTF offers a viable answer without compromising on print quality.

Furthermore, the durability of UV DTF prints means that products are less likely to need replacement, which contributes to less waste over time. By choosing this printing technology, businesses not only improve their product offerings but also play a role in promoting sustainable practices. This eco-friendly approach appeals to a growing market segment that values environmentally responsible decisions.

Getting Started: A Beginner’s Guide to UV DTF Printing

For anyone interested in venturing into UV DTF printing, understanding the equipment and materials involved is crucial. Start by familiarizing yourself with various printer specifications, as not all models are suitable for every material. Researching the right inks is similarly important; high-quality UV inks are essential for achieving vibrant and durable prints. Investing in a good printer alongside premium inks sets the foundation for successful printing endeavors.

Additionally, mastering the selection of films is vital in the DTF process. The choice of film can greatly influence the outcome of prints, from color vibrancy to adhesion. Beginners should experiment with different film types to discover which works best for their specific needs. Attending workshops or following online tutorials can also provide beneficial insights for those new to UV DTF printing, enabling them to create stunning products efficiently.

Future Trends in UV DTF Printing Technology

As technology continues to evolve, the landscape of UV DTF printing is set for exciting advancements. New machines are entering the market that enhance productivity, reduce operational costs, and improve print quality. These innovations cater to the increasing demand from businesses seeking to scale their production capabilities without sacrificing quality. Staying informed about the latest developments in UV printing technology is vital for anyone looking to keep their processes competitive.

In addition, the demand for personalized and unique designs is on the rise, pushing manufacturers to innovate further. As more businesses recognize the advantages of UV DTF printing, we can expect ongoing enhancements aimed at increasing efficiency and expanding the range of printable materials. This forward momentum in technology positions UV DTF printing as a leading choice in the world of custom printing, appealing to both beginners and seasoned professionals alike.

Frequently Asked Questions

What is UV DTF printing and how does it work?

UV DTF printing, or UV Direct to Film printing, combines advanced UV printing technology with a direct to film method. In this process, high-quality inks are applied to a film substrate and instantly cured with ultraviolet light, resulting in vibrant and durable prints.

What are the advantages of using UV DTF printing over traditional methods?

The advantages of UV DTF printing include superior durability and longevity of prints, versatile substrate compatibility, and eco-friendly ink options. UV-cured inks resist fading and scratching, making them ideal for both indoor and outdoor applications.

Can I use UV DTF printing for custom apparel projects?

Yes, UV DTF printing is highly effective for custom apparel projects. It allows for vibrant designs on a variety of materials including cotton and polyester, ensuring that your garments maintain their quality over time.

What types of substrates can be printed using UV DTF technology?

UV DTF technology can print on a wide range of substrates, including cotton, polyester, leather, and even hard surfaces. This versatility makes it suitable for various applications such as custom apparel, promotional products, and interior decor.

How do I get started with UV DTF printing as a beginner?

To get started with UV DTF printing, research the necessary equipment, choose high-quality UV inks, and familiarize yourself with the types of films used. Additionally, consider attending training sessions to enhance your skills and understanding of the process.

What market trends should beginners know about UV DTF printing?

Beginners should be aware that the UV DTF printing market is rapidly evolving with new advancements in technology, leading to increased productivity and reduced production costs. Staying informed about these trends can help you leverage UV DTF for business growth.

| Key Point | Details |

|---|---|

| Introduction to UV DTF Printing | A revolutionary technique that combines UV printing with the DTF process, curing inks with UV light on a special film. |

| What is UV DTF Printing? | Involves applying ink to film substrate which is cured instantly with UV light, allowing for quick handling post-printing. |

| Advantages of UV DTF Printing | 1. **Durability**: UV-cured inks resist fading, scratching, and weathering. 2. **Compatibility**: Works on a variety of substrates including cotton, polyester, and leather. 3. **Eco-Friendly**: Emits fewer VOCs, safer for the environment. |

| Applications of UV DTF Printing | – **Custom Apparel**: T-shirts, hats, and garments maintain vibrant designs. – **Promotional Products**: High-quality prints on bags, mugs, and stationery. – **Interior Decor**: Wall art and decorative items with unique designs. |

| Trends in UV DTF Printing Market | Advancements in technology leading to new machines that boost productivity and reduce production costs. |

| Getting Started in UV DTF Printing | 1. Research equipment specifications. 2. Invest in high-quality UV inks. 3. Familiarize with types of films used. 4. Seek training and practice. |

Summary

UV DTF Printing is an innovative and effective printing technique that combines the benefits of UV printing with Direct to Film technology. This unique process provides remarkable durability and vibrant colors across a variety of substrates, making it suitable for numerous applications including custom apparel, promotional products, and decorative items. As businesses and individuals lean towards eco-friendly solutions, UV DTF printing stands out due to its reduced environmental impact. For newcomers, understanding the equipment, materials, and techniques involved is essential for leveraging the full potential of UV DTF printing. With rapid technological advancements and an expanding market, now is the perfect time to explore this exciting area of printing.