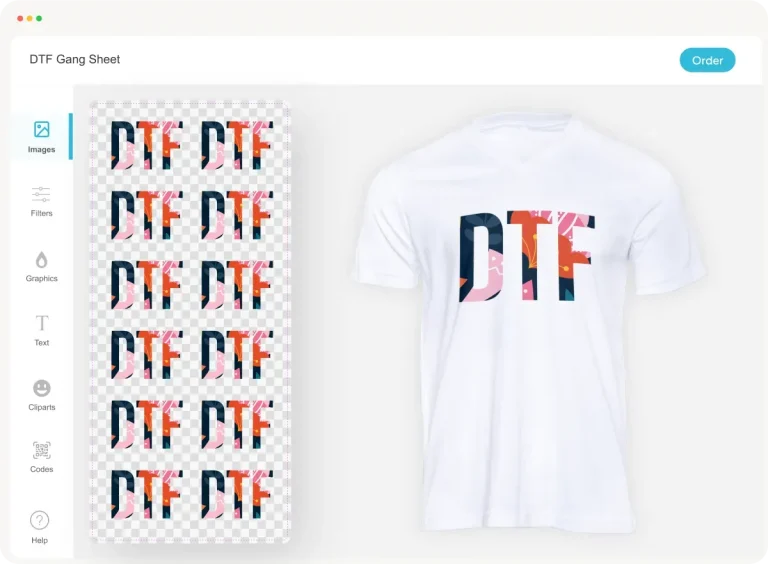

UV DTF Gangheet is revolutionizing the printing landscape by combining the benefits of UV printing with the versatility of direct-to-film technology. This innovative approach offers unmatched print quality and durability, making it a preferred choice over traditional printing methods. As businesses seek ways to elevate their branding and product visibility, the efficiency of UV DTF stands out, allowing for stunning results in a fraction of the time. Additionally, the print quality comparison between UV DTF and options like screen printing reveals a significant edge in color vibrancy and detail precision. With its capability to withstand various environmental factors, the durability in printing provided by UV DTF Gangheet ensures that designs remain intact and visually appealing for longer periods.

Exploring the landscape of UV Direct to Film (DTF) technology unveils a realm of possibilities for modern printing solutions. This method, which utilizes ultraviolet light for curing inks onto film, is redefining the way prints are produced, bringing efficiency and craftsmanship to the forefront. Alternative terms such as UV print technology spotlight its capacity for rapid production and adaptability to a wide range of materials. As the printing industry shifts towards innovation, high-quality outputs are no longer just a requirement but an expectation; thus, understanding the nuances of UV DTF compared to conventional processes becomes essential. With advancements continuously influencing durability and application versatility, the rise of DTF technology marks a significant turning point in print manufacturing.

Understanding UV DTF Gangheet Technology

At the forefront of modern printing, **UV DTF Gangheet** technology leverages the power of ultraviolet light to transform the printing landscape. This method stands out due to its ability to produce exceptional quality prints with incredible vibrancy and detail. Unlike traditional methods, UV DTF does not rely on water-based inks, which can often lead to color fading and inconsistencies over time. Instead, the UV curing process solidifies the ink almost immediately as it hits the surface, resulting in crisp and vibrant outputs that are nothing short of spectacular.

The unique mechanisms behind **UV DTF Gangheet** not only enhance print quality but also increase durability and efficiency. Notably, this technology is resilient against environmental factors, making it suitable for both indoor and outdoor applications. As industries seek to produce visually striking and long-lasting products, the adoption of **UV DTF** has surged, demonstrating its powerful competitive edge over traditional printing techniques.

Print Quality Comparison: UV DTF Gangheet vs. Traditional Methods

When evaluating print quality, **UV DTF Gangheet** emerges as a leader, offering a remarkable range of colors and superb detail. This method excels when it comes to producing complex designs that demand precision. In contrast, traditional printing methods like screen printing require multiple setups for various colors, which can introduce inconsistencies in the final product. The meticulous nature of traditional printing can lead to a longer turnaround time, making **UV DTF** a more attractive option for businesses aiming for impeccable quality without sacrificing time.

Furthermore, the capability of **UV DTF** to create high-resolution images makes it particularly effective for items such as promotional materials, merchandise, and even fine art reproductions. With its vast color gamut and fine detail—qualities often challenged by traditional techniques—**UV DTF Gangheet** sets a new benchmark for print quality, ensuring that businesses can offer their customers the best possible products.

Speed and Efficiency in Printing

Speed is a significant factor to consider in any printing operation, and here, **UV DTF Gangheet** excels. The rapid curing process allows for much quicker production times compared to traditional methods that require extensive preparation and drying times. In essence, while a traditional screen printing setup might take hours to prepare and adjust for multiple colors, **UV DTF** can deliver finished products in a fraction of the time. This efficiency makes it particularly valuable for businesses that face tight deadlines or unexpected high volumes.

This heightened efficiency not only streamlines operations but also enhances overall productivity. When businesses can promise quick turnarounds, they are better positioned to tackle multiple projects simultaneously, ensuring they remain competitive in markets that demand speed alongside quality. Thus, the choice of **UV DTF Gangheet** presents a powerful advantage for those seeking rapid output without compromising on the quality of printing.

Durability in Print: How UV DTF Outshines Traditional Methods

Durability is a critical factor in printing, especially for products exposed to various environmental conditions. **UV DTF Gangheet** technology offers superior resistance to fading, scratches, and moisture due to the robust nature of UV-cured inks. This characteristic makes it an ideal choice for products like outdoor signage, apparel, and promotional items that require longevity and resilience. Customers favor businesses that provide items that they know will withstand the test of time, and **UV DTF** fulfills this requirement admirably.

In contrast, traditional printing methods can exhibit variability in durability. For instance, while some techniques may incorporate protective coatings, they still cannot compete with the inherent strength of UV-cured prints. Traditional ink processes can lead to issues of color degradation and surface wear over time, particularly in demanding settings. Therefore, by opting for **UV DTF Gangheet**, businesses can confidently assure their clients of a durable, high-quality product.

Material Versatility: A Key Advantage of UV DTF Gangheet

One of the standout features of **UV DTF Gangheet** is its unparalleled versatility in material compatibility. This innovative printing method can effectively print on a wide array of substrates—ranging from soft textiles to hard surfaces like wood, metal, and plastics. Such flexibility allows businesses and creatives to explore diverse applications beyond the limitations typically posed by traditional techniques.

In traditional printing, methods often pigeonhole users to specific materials; for example, screen printing is primarily suited for fabrics, while offset printing primarily caters to paper. This inherent restriction can stifle creative opportunities and limit the scope of projects. In contrast, the expansive adaptability of **UV DTF** means that creators can fully realize their visions across multiple formats and materials, enhancing their product offerings and market reach.

Cost-Efficiency: Evaluating UV DTF Gangheet Impact on Budgets

While the initial investment in **UV DTF Gangheet** technology may appear significant, the long-term benefits can lead to substantial cost savings. The efficiency gains from quicker production times, combined with lower labor costs due to reduced setup needs, can offset these upfront expenses. Businesses often find that the scalability of **UV DTF** technology allows them to handle larger orders without additional financial strain, positively impacting their overall profitability.

In contrast, while traditional printing methods may offer a lower starting point for production costs, they can quickly escalate due to increased labor for setup and the potential need for more expensive materials for consistent quality. This hidden expense can potentially undermine the perceived cost-effectiveness of conventional techniques. Therefore, many organizations are re-evaluating their options, finding that adopting **UV DTF Gangheet** not only meets their quality needs but also aligns closely with their budgetary goals.

Frequently Asked Questions

What are the advantages of UV DTF Gangheet over traditional printing methods?

UV DTF Gangheet offers numerous advantages including superior print quality, faster production speeds, and enhanced durability compared to traditional printing methods. The vibrant color reproduction and intricate detail make it ideal for a variety of applications, while the quick curing process boosts efficiency, allowing businesses to handle multiple orders effectively.

How does UV DTF Gangheet compare in terms of print quality with traditional printing methods?

When comparing UV DTF Gangheet to traditional printing methods, UV DTF excels in print quality. It can achieve vibrant colors and intricate details with a wider color gamut, surpassing the capabilities of traditional methods like screen printing, which may lose consistency across color layers.

Can UV DTF Gangheet prints withstand various environmental conditions better than traditional printing?

Yes, UV DTF Gangheet prints exhibit exceptional durability, making them resistant to fading, scratches, and moisture. This superior durability ensures that prints maintain their appearance over time, even in challenging environments, unlike many traditional printing methods that may suffer from wear.

What types of materials can UV DTF Gangheet effectively print on compared to traditional methods?

UV DTF Gangheet is known for its versatility, able to print on a wide range of materials including textiles, wood, metal, and plastic. In contrast, traditional printing methods often have specific material limits, which can constrain creative possibilities depending on the method used.

Is UV DTF Gangheet cost-efficient compared to traditional printing techniques?

While the initial investment in UV DTF Gangheet technology may be higher, it often proves more cost-efficient in the long run due to reduced labor costs and faster production times. Traditional printing may feel more budget-friendly for large runs, but increased setup and labor costs for smaller projects can offset these perceived savings.

What recent advancements have been made in UV DTF Gangheet technology?

Recent advancements in UV DTF Gangheet technology have focused on improving ink formulations for better color accuracy and adhesion. These developments enhance the method’s applicability across various commercial projects, solidifying its position as a competitive alternative to traditional printing methods.

| Aspect | UV DTF Gangheet | Traditional Printing |

|---|---|---|

| Quality of Print | Unparalleled quality with vibrant colors and intricate details. | Can deliver good quality, but requires multiple color passes, affecting consistency. |

| Speed and Efficiency | Rapid curing process, significantly reducing production times. | Slower due to multiple setups for each color, leading to increased labor costs. |

| Durability | Highly durable, resistant to fading, scratches, and moisture. | Durability varies; can fade or wear under harsh conditions. |

| Material Versatility | Can print on a wide range of materials including textiles, wood, plastic, and metal. | Specific methods suited for specific materials, limiting versatility. |

| Cost-Efficiency | Higher initial investment but lower long-term costs due to efficiency and reduced labor. | Appears cheaper for large runs, but costs can increase for smaller jobs. |

Summary

UV DTF Gangheet represents a transformative leap in printing technology, offering unmatched benefits over traditional methods. This cutting-edge approach excels in producing high-quality prints with vibrant colors, rapid production speeds, outstanding durability, and versatile material compatibility. As businesses seek to keep pace with rising demands for high-caliber outputs, the adoption of UV DTF Gangheet can pave the way for improved efficiency and creativity. Whether you are in the market for a reliable, long-lasting printing solution or looking to explore new possibilities in design, UV DTF Gangheet stands out as the premier choice to elevate your projects.