In the rapidly evolving realm of custom apparel printing, **UV DTF Gangheet** stands out as an innovative technique that merges traditional printing with state-of-the-art UV printing technology. This groundbreaking method not only allows for high-quality, vibrant designs but also caters to the increasing demand for personalization in fashion. As consumers gravitate towards unique clothing options, UV DTF Gangheet offers an efficient and sustainable printing solution that meets diverse preferences and trends. With its exceptional durability and versatility across various materials, this printing technology showcases a brighter future for the custom apparel printing industry. Join us as we delve deeper into the benefits, market trends, and future prospects of UV DTF Gangheet printing, a key player in shaping apparel printing trends.

Exploring the realm of direct to film printing has introduced us to remarkable innovations like UV DTF Gangheet printing, a method that enhances the capabilities of fabric decoration. This revolutionary technique utilizes ultraviolet inks to ensure that designs last longer and look brilliant, making it perfect for custom apparel. As the market pivots towards sustainable printing options, more businesses are leveraging this technology to meet consumer demands for eco-friendly solutions. By combining various print designs on a single film, UV DTF Gangheet optimizes production, reducing waste while staying aligned with current apparel printing trends. In this discussion, we will uncover the significance of this printing advancement and its role in reshaping the landscape of fabric printing.

Understanding UV DTF Gangheet Printing

UV DTF Gangheet printing is a cutting-edge process that merges the strengths of traditional printing methods with advanced UV technology. This printing technique utilizes a special film, allowing for the high-quality transfer of vibrant images directly onto various materials, particularly in the apparel industry. The ‘Gangheet’ aspect refers to the sophisticated ability to lay multiple designs on a single transfer film, significantly optimizing production processes. This innovative approach not only reduces material waste but also caters to the increasing demand for personalized apparel.

With the evolution of consumer preferences leaning towards unique and personal designs, UV DTF Gangheet printing stands out as a solution. This method enables businesses to produce multiple designs simultaneously, streamlining production and enabling faster service delivery. As a result, apparel brands can cater to individual consumer needs while maintaining high printing standards, ensuring that their products remain competitive in a saturated market.

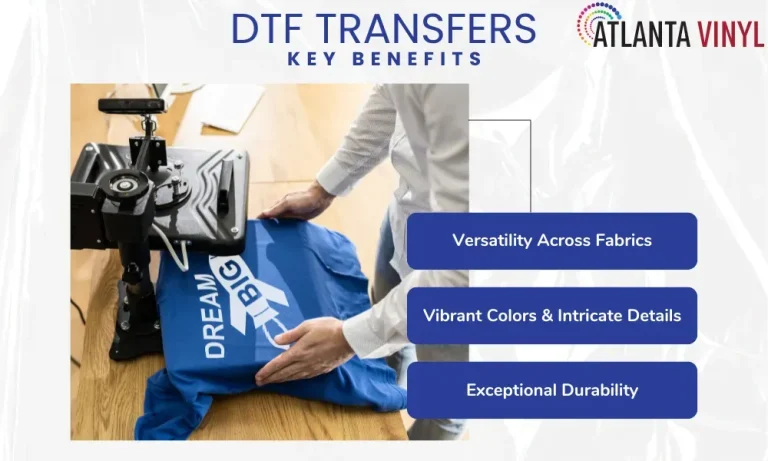

Benefits of UV DTF Printing in Custom Apparel

One of the primary advantages of UV DTF printing is its unmatched durability. The specialized UV inks used in this method are designed to withstand wear and tear, ensuring that prints remain vibrant and intact even after multiple washes. This longevity is a key selling point for brands aiming to deliver high-quality products that exceed consumer expectations. In an industry where product quality can directly influence sales, the durability of UV DTF prints positions businesses favorably against competitors.

Another significant benefit is the ability of UV DTF printing to produce exceptionally bright and vivid colors. As visual appeal is crucial in the fashion industry, having a printing method capable of maintaining color integrity while achieving intricate designs is invaluable. This technology allows for a wider color spectrum and finer details, providing apparel brands the opportunity to create eye-catching designs that resonate with their target audience.

Sustainability in UV DTF Gangheet Printing

As sustainability becomes increasingly critical in today’s market, UV DTF Gangheet printing technology has made strides toward eco-friendly practices. The development of UV inks that are less harmful to the environment is an essential advancement, as brands look to align their production methods with consumer values. Eco-conscious customers are actively seeking businesses that make sustainable choices, and implementing UV DTF technology with green inks can significantly enhance a brand’s reputation.

Moreover, the efficiency of UV DTF printing reduces waste through its ability to utilize a single film for multiple designs. This not only minimizes resource consumption but also lowers the environmental footprint of the printing process. Companies committed to sustainability can leverage this printing technique to uphold environmental responsibilities while simultaneously meeting the demands of an increasingly eco-aware consumer base.

Current Market Trends Influencing UV DTF Printing Adoption

The custom apparel market is undergoing significant transformation, with personalization at the forefront. As consumers increasingly seek out unique products, UV DTF printing stands out as a relevant solution. Customization options provided through this printing method enable businesses to cater to individual preferences, thereby enhancing customer satisfaction and engagement. Companies investing in UV DTF technology can ensure they are meeting the evolving demands of the market effectively.

Additionally, the rise of e-commerce has fueled the adoption of UV DTF printing technologies. Online platforms that allow users to upload custom designs or select from premade templates are thriving, thanks to the efficiency and versatility of this printing method. Businesses can quickly adapt to consumer trends and deliver products that meet the growing expectations for personalized apparel in an increasingly digital marketplace.

The Future of UV DTF Gangheet Printing Technology

Looking toward the future, the prospects for UV DTF Gangheet printing technology are exceptionally promising. Experts predict that advancements in UV printing technology will continue, leading to quicker drying times and reduced production bottlenecks. These innovations will enable businesses to turn around orders faster, cater to last-minute demands, and ultimately improve customer service. Such advancements will be vital for companies that need to maintain a competitive edge in a fast-paced industry.

Furthermore, the integration of automation and AI into the UV DTF printing process holds exciting potential. By streamlining operations, businesses can enhance efficiency, reduce costs, and focus on quality improvements. This automation will not only simplify the printing process but also enable small and medium-sized enterprises to access advanced production technologies that were once reserved for larger manufacturers, democratizing high-quality custom apparel printing.

Challenges to Consider When Implementing UV DTF Gangheet Printing

Despite the clear advantages, adopting UV DTF Gangheet printing does come with its set of challenges. One of the primary considerations is the initial investment involved in acquiring the necessary equipment, which can be prohibitively expensive for smaller firms. However, it’s essential for businesses to weigh this upfront cost against the long-term savings from reduced material waste and labor costs, understanding that the right investment can yield significant returns over time.

Another challenge is the learning curve that accompanies advanced UV printing technology. Employees will require training to operate the machinery effectively and harness its full potential. While this may introduce short-term operational hurdles, properly educating staff can lead to enhanced skill sets that improve productivity and product quality in the long run.

Frequently Asked Questions

What is UV DTF Gangheet printing and how does it work in custom apparel printing?

UV DTF Gangheet printing is an advanced printing technology that utilizes ultraviolet (UV) inks to create high-quality images on special transfer films. These films are heat-pressed onto a variety of materials, allowing for vibrant and durable designs in custom apparel printing.

What are the benefits of using UV DTF Gangheet in apparel printing trends?

The benefits of UV DTF Gangheet include high durability against wear and washing, vivid color reproduction, versatility across various fabrics, and the availability of eco-friendly printing options, making it a leading trend in custom apparel printing.

How does UV DTF Gangheet compare to traditional direct-to-film printing?

Unlike traditional direct-to-film printing, UV DTF Gangheet printing employs UV technology, resulting in faster curing times and producing brighter colors with enhanced durability, making it superior for custom apparel applications.

Can UV DTF Gangheet printing be considered a sustainable printing option?

Yes, UV DTF Gangheet printing can be considered a sustainable printing option as it uses eco-friendly UV inks that reduce environmental impact while maintaining high-quality print results, appealing to eco-conscious consumers.

What is the potential of UV DTF Gangheet printing in the customization of apparel?

The potential of UV DTF Gangheet printing in apparel customization is promising, as it allows for the production of tailored designs efficiently, meeting the growing consumer demand for personalized items in the custom apparel market.

What challenges do businesses face when adopting UV DTF Gangheet printing technology?

Businesses adopting UV DTF Gangheet printing may face challenges such as the initial investment cost of equipment and the learning curve required for staff training. However, the long-term benefits in efficiency and quality can outweigh these challenges.

| Aspect | Details |

|---|---|

| What is UV DTF Gangheet Printing? | A modern printing technology that utilizes UV inks to print high-quality images on transfer films, which can then be heat-pressed onto fabrics. |

| Advantages | 1. High Durability: Resistant to scratching, fading, and washing. 2. Vibrant Colors: Produces bright, high-quality prints. 3. Versatility: Works on various fabrics like cotton and polyester. 4. Eco-Friendly: Offers sustainable ink options. |

| Current Market Trends | Increasing demand for personalization in fashion; e-commerce growth driving customization options directly for consumers. |

| Future Prospects | 1. Reduced drying times for faster production. 2. More eco-friendly ink formulations. 3. Automation and AI integration for efficiency. |

| Challenges | 1. High initial investment costs. 2. Requires training to operate advanced equipment. |

Summary

UV DTF Gangheet printing is poised to revolutionize the custom apparel printing industry through its remarkable durability, vibrant color output, versatility across materials, and commitment to eco-friendly alternatives. As consumer preferences increasingly shift towards personalized and unique designs, this innovative printing technique not only meets these demands but also enhances production efficiency with advancements like automation and improved drying times. Despite the challenges of initial investment and operational training, the long-term benefits of UV DTF Gangheet printing highlight its potential to elevate businesses in the competitive apparel market. Brands that embrace this technology can look forward to exciting opportunities as the landscape of fashion and custom printing continues to evolve.