In the dynamic realm of printing technology, **UV DTF Gangheet** stands as a remarkable innovation, seamlessly integrating UV printing technology with Direct to Film (DTF) printing methods. This revolutionary approach has transformed traditional printing processes, enabling businesses to produce stunning visuals directly onto a variety of surfaces with unprecedented efficiency. With UV DTF Gangheet, vibrant colors and intricate designs come to life, making it an ideal choice for custom print solutions that demand durability and precision. As the printing industry trends shift towards sustainable and high-quality methods, the versatility of this technology captures the attention of businesses eager to enhance their offerings. Join us as we explore the ins and outs of UV DTF Gangheet, uncovering its advantages, challenges, and a multitude of applications across diverse sectors.

UV DTF Gangheet, also known as ultraviolet Direct to Film printing, represents a substantial leap forward in custom print technology. This technique combines the rapid curing properties of UV inks with the flexibility of DTF methods, allowing for detailed and vivid graphics to be transferred onto multiple substrates. In today’s competitive marketplace, where high-quality prints and customization are paramount, this innovative printing technique offers a compelling solution for businesses aiming to stand out. As manufacturers continue to refine these processes and explore new applications, understanding the nuances of UV DTF methods becomes essential for stakeholders in the printing industry. Embracing advanced printing technologies like this not only enhances product quality but also positions companies at the forefront of industry trends.

The Evolution of UV Printing Technology

UV printing technology has revolutionized the printing industry by introducing innovative methods that enhance the quality and versatility of printed materials. With the advent of UV inks that cure almost instantly upon exposure to ultraviolet light, businesses have witnessed a significant improvement in the vibrancy and durability of their print products. This technology allows for printing on a multitude of surfaces, from flexible materials like textiles to rigid substrates such as metals and plastics, expanding creative possibilities for designers and brands alike.

The evolution of UV printing has also paved the way for hybrid solutions, such as UV DTF (Direct to Film) printing, which combines the benefits of direct ink application with the preciseness of film printing. This blend ensures that detailed imagery can be transferred seamlessly onto various surfaces, catering to the increasing demand for customized print solutions in diverse industries. As the printing industry continues to embrace these advancements, we expect to see further developments in speed and efficiency, alongside a growing integration of environmentally friendly practices.

Understanding Direct to Film Printing

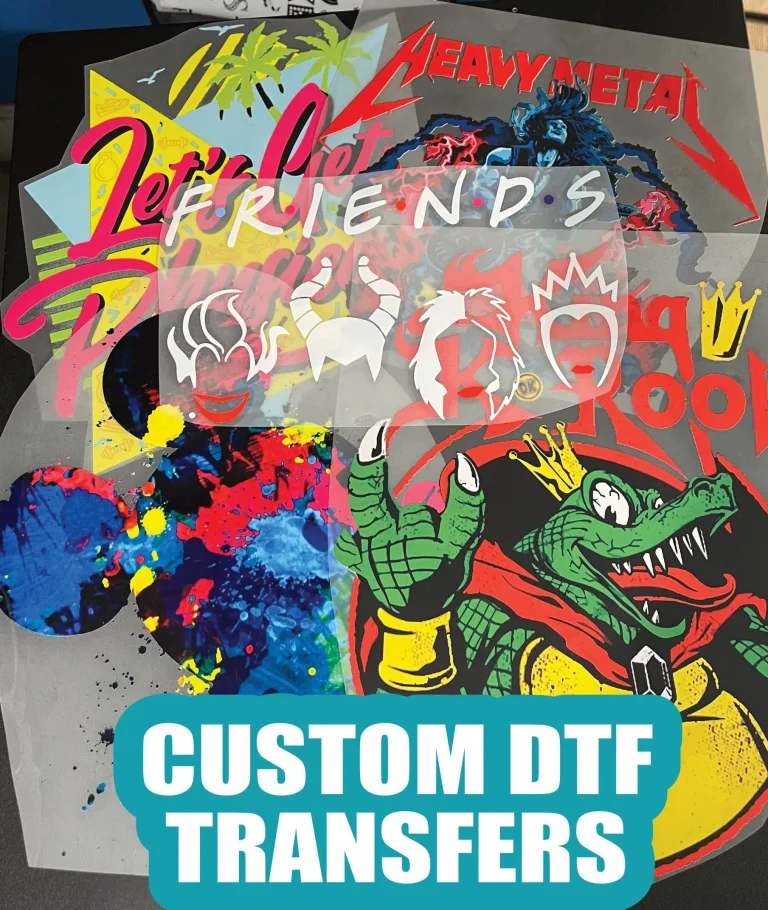

Direct to Film (DTF) printing has emerged as a prominent technique in the printing landscape, offering an effective means of transferring high-quality designs onto various substrates. The process involves printing designs onto a specially formulated film, which is then applied to the desired surface using heat and pressure. This approach allows for intricate details and vibrant colors that stand out without compromising the integrity of the substrate, making it popular among custom apparel producers and promotional product manufacturers.

Moreover, DTF printing is particularly valued for its ability to create long-lasting prints that withstand wear and tear over time. The films used in this method are designed for exceptional adhesion, ensuring that prints remain intact through multiple washes and everyday use. As consumer demand for unique and personalized products continues to grow, the flexibility of DTF printing positions it as a vital component in the toolkit of modern printing businesses, aligning perfectly with trends toward customization and quality.

Emerging Trends in the Printing Industry

The printing industry is currently undergoing rapid transformations, largely driven by advancements in technology and changing consumer preferences. One of the most notable trends is the increasing demand for sustainable printing practices. Consumers are becoming more environmentally conscious, prompting printers to find eco-friendly solutions, such as UV inks with lower levels of volatile organic compounds (VOCs). This trend not only benefits the environment but also fulfills the expectations of customers looking for responsibly produced products.

Additionally, the shift toward personalization is reshaping the market landscape. Businesses are now seeking customizable print solutions that cater to individual preferences, fostering a culture of uniqueness among consumers. Technologies like UV DTF Gangheet are perfectly positioned to meet this demand, enabling brands to offer tailored products that resonate well with their target audience and enhance customer loyalty.

Advantages of UV DTF Gangheet in Various Industries

UV DTF Gangheet offers a multitude of advantages that make it a favorable choice across various industries. One of its most significant benefits is versatility; it allows printing on a wide array of materials, such as textiles, ceramics, and metals. This capability equips businesses with the freedom to explore new product lines and creative applications, enabling them to stand out in competitive markets.

Moreover, durability is a hallmark of UV DTF prints. The UV-cured inks provide an exceptional level of resistance against fading and scratches, making them suitable for both indoor and outdoor applications. This longevity not only improves the quality of the final product but also assures customers of their investment, as they receive items that maintain their aesthetic appeal over time. As businesses increasingly prioritize product quality, the adoption of UV DTF Gangheet technology is likely to gain momentum.

Challenges and Opportunities in UV DTF Printing

While UV DTF printing presents exciting opportunities, it is not without its challenges. The initial investment costs associated with high-quality UV DTF printers can be a barrier for some businesses, especially small to medium enterprises. However, as technology continues to evolve, prices are gradually decreasing, making this innovative solution more accessible to a broader range of printing companies.

In addition, technical expertise is essential for maximizing the benefits of UV DTF printing. Operators require specialized training to navigate the intricacies of equipment and to harness the full potential of this technology. Thus, while the challenges may seem daunting, they also represent an opportunity for businesses willing to invest in skill development and adaptation, ultimately positioning themselves for success in a competitive printing landscape.

Transforming the Fashion Industry with UV DTF Gangheet

The fashion industry stands as one of the most significant beneficiaries of UV DTF Gangheet technology. Custom apparel brands are leveraging this innovative printing method to create one-of-a-kind clothing pieces that feature vibrant graphics and intricate designs. This capability allows designers to experiment more freely, pushing creative boundaries while appealing to consumers’ desires for personalized fashion.

Moreover, UV DTF provides a competitive edge by facilitating efficient production processes. With the ability to print in bulk on various materials, apparel companies can meet high demand without compromising on quality. As trends toward personalized and sustainable fashion continue to intensify, the adoption of UV DTF Gangheet could play a central role in shaping the future of the industry, driving both creativity and profitability.

Frequently Asked Questions

What are the main benefits of using UV DTF Gangheet in printing?

UV DTF Gangheet offers numerous benefits, including exceptional durability, vibrant color quality, and versatility across various substrates. This innovative printing method uses UV inks that are instantly cured under ultraviolet light, ensuring long-lasting prints resistant to fading and wear. It’s an eco-friendly option as it typically involves low levels of volatile organic compounds (VOCs), making it suitable for businesses seeking sustainable printing solutions.

How does the UV DTF Gangheet printing process work?

The UV DTF Gangheet printing process involves two key phases: first, designs are printed onto a specialized film using UV inks, which cure immediately under UV light, allowing for intricate and colorful designs. In the second phase, this printed film is transferred to a wide variety of materials, including textiles and hard surfaces, using heat and pressure, resulting in high-quality, durable prints.

What industries can benefit from UV DTF Gangheet technology?

Various sectors can leverage UV DTF Gangheet technology, including the fashion industry for custom apparel, promotional products for unique merchandise, signage for creating high-resolution displays, and any business seeking custom print solutions. This technology’s versatility allows for creative applications such as personalized products and intricate designs on different surfaces.

Is UV DTF Gangheet a cost-effective printing method?

While the initial investment in UV DTF printing equipment can be high, the potential for high-quality, durable prints and the versatility it offers can lead to cost-effectiveness in the long run. As technology advances and more models become available, prices are decreasing, making UV DTF Gangheet a viable option for small and medium-sized enterprises looking to expand their printing capabilities.

What are the current trends in the UV DTF printing industry?

Current trends in the UV DTF printing industry include an increasing demand for customized products, advances in manufacturing technology that enhance printing speed and resolution, and a growing focus on sustainable practices with eco-friendly inks. As businesses strive to differentiate their offerings, the popularity of UV DTF Gangheet continues to rise, reflecting these industry dynamics.

What challenges might one face when adopting UV DTF Gangheet technology?

Adopting UV DTF Gangheet technology can present challenges such as the high cost of initial equipment and the need for technical expertise in operating the printers. Although the technology is becoming more accessible, businesses may require training to fully exploit its capabilities and achieve optimal results in their printing processes.

| Aspect | Details |

|---|---|

| What is UV DTF Gangheet? | A printing method using UV ink that cures instantly under UV light, transferring vibrant, durable designs onto various materials. |

| Printing Process | 1. Film Printing: Design is printed on a special film using UV inks. 2. Transfer to Material: The film is applied onto the substrate with heat and pressure. |

| Market Trends | The UV DTF printing market is rapidly growing, particularly among SMEs seeking to customize offerings without heavy investments. |

| Advantages | 1. Versatility in printing on multiple substrates. 2. High durability against fading and wear. 3. Eco-friendly due to low VOCs in inks. |

| Challenges | 1. High initial equipment costs. 2. Requires technical expertise for effective operation. |

| Industry Applications | 1. Fashion (custom apparel) 2. Promotional products 3. Signage 4. Custom products (e.g., shoes, décor items) |

Summary

UV DTF Gangheet technology represents a groundbreaking advancement in the printing industry, revolutionizing how graphics and designs are applied to diverse surfaces. This innovative method merges the efficiency of UV printing with the flexibility of Direct to Film printing, allowing for stunningly vibrant and durable prints that cater to various industries—from fashion to promotional products. With its capability to enhance creativity while maintaining sustainability, UV DTF Gangheet is quickly becoming an essential tool for businesses aiming to elevate their printing capabilities and meet consumer demand for quality customization. As businesses adopt this technology, they position themselves to stand out in a competitive market.