In the realm of modern printing, UV DTF Gangheet stands at the forefront, marrying the innovative techniques of UV printing technology with the efficiency of Direct to Film (DTF) printing. This powerful convergence revolutionizes the way vibrant, durable designs are created and applied across various materials. UV DTF Gangheet not only enhances printing precision but also accelerates production processes, making it a go-to choice for custom printing needs. By leveraging the strengths of both UV and DTF methods, this technique delivers outstanding quality and vividness that captivates customers’ attention. As we dive into the intricacies of UV DTF Gangheet, we will uncover its workflow, advantages, and the plethora of applications it supports in today’s dynamic market.

The innovative landscape of custom printing has been transformed with advancements like UV DTF printing, also known as Gangheet. This method blends powerful Direct to Film technology with the advantages of ultraviolet ink application, allowing for high-quality, vibrant prints to be produced quickly. By utilizing cutting-edge printing processes, businesses can now engage in modern printing techniques that meet diverse needs while minimizing waste and maximizing efficiency. Whether it’s for corporate branding or personalized gifts, the versatility of Gangheet printing enables designers and companies to produce exceptional products quickly and effectively. In this discussion, we will explore how this modern method impacts the printing industry and the significant benefits it offers.

What is UV DTF Gangheet?

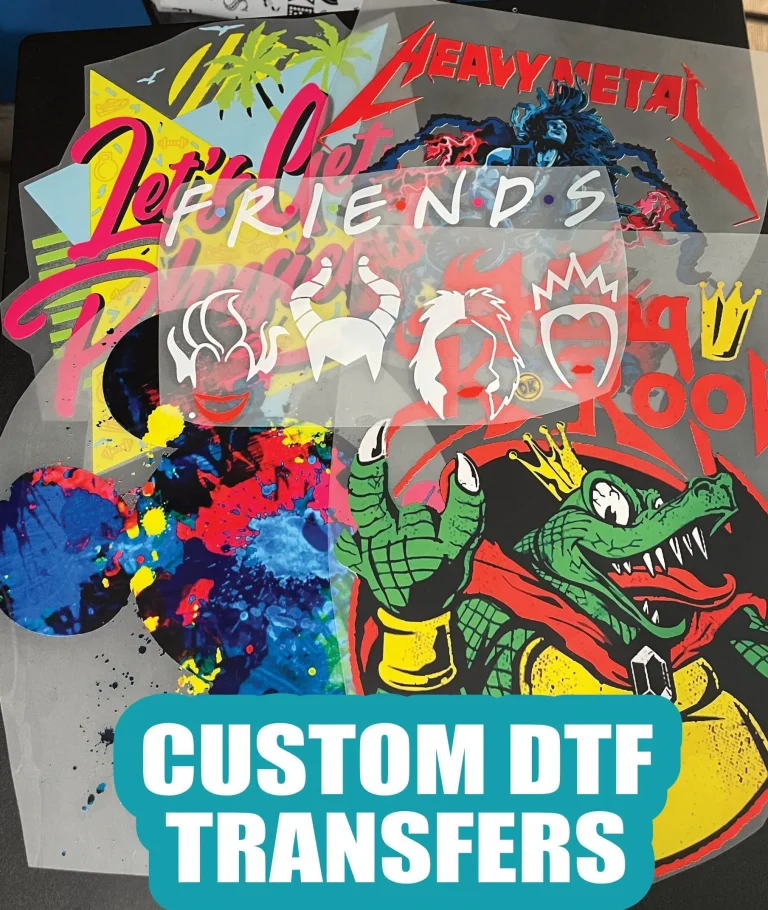

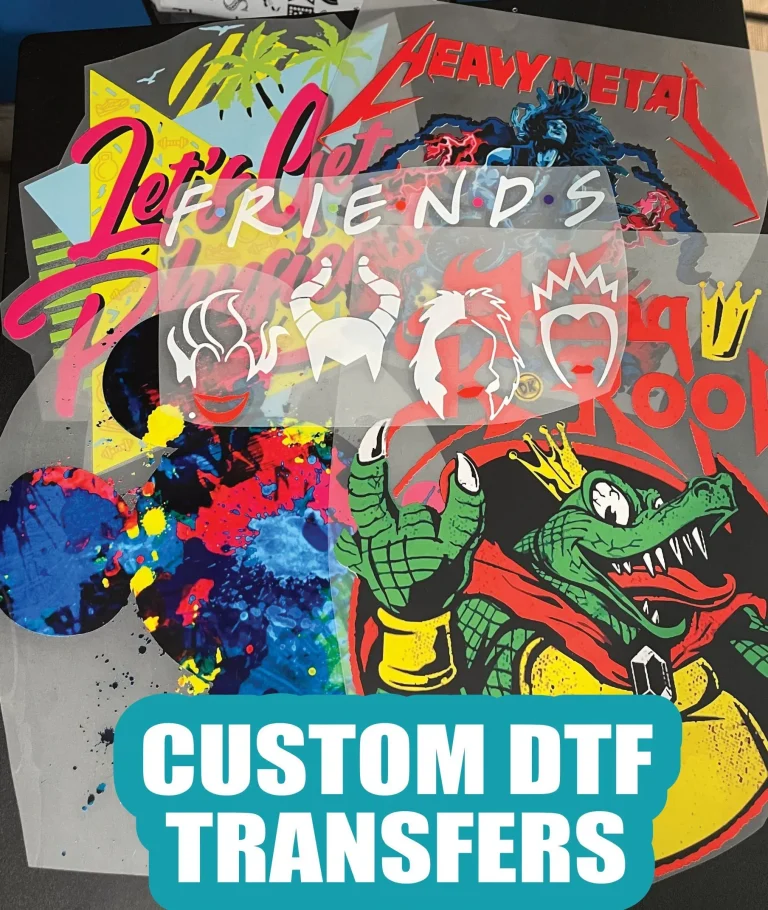

UV DTF Gangheet represents a groundbreaking synergy between UV printing technology and Direct to Film (DTF) methods, establishing a new standard in custom printing. By utilizing specialized UV inks that cure instantly under ultraviolet light, this technique transforms the way we approach print production. The combination not only ensures vibrant, sharp images but also enhances the durability of printed products, making them suitable for a variety of applications from apparel to promotional items.

In essence, UV DTF Gangheet involves printing designs onto a transfer film, which is later applied to a variety of surfaces with remarkable precision. This approach simplifies the process of creating high-quality prints, allowing businesses to deliver products that meet consumer expectations for both aesthetics and durability. As the technology advances, the possibilities for custom printing continue to expand, opening avenues for innovative designs and applications.

Advantages of UV DTF Printing Technology

One of the standout advantages of UV DTF printing technology is its rapid production speed. Unlike traditional printing methods that require lengthy drying times, UV inks cure instantly when exposed to UV light, allowing for immediate handling and shipping of printed items. This efficiency is crucial for businesses, especially those dealing with tight deadlines or high-demand orders, as it translates to improved customer satisfaction and increased turnover.

Additionally, UV DTF Gangheet reduces waste by facilitating on-demand printing that eliminates the need for large inventory runs. With this method, companies can easily customize batches without overcommitting resources or materials, significantly minimizing environmental impact. Therefore, it aligns with sustainable practices while still delivering impressive results that do not compromise on quality.

Exploring Workflow of UV DTF Gangheet

The workflow of UV DTF Gangheet is streamlined yet thorough, consisting of crucial steps that ensure the highest quality output. Initially, the design is crafted using advanced graphic software, incorporating elements such as color profiles and texture considerations that enhance the overall visual appeal. This meticulous preparatory stage sets the foundation for successful printing, underpinning the significance of professional design in the UV DTF process.

Following the design phase, the actual printing occurs on a specialized transfer film using UV printers. The curing process happens almost instantaneously, allowing designers to see their visions materialize in real-time. The subsequent application of the printed film onto various substrates, facilitated by the versatility of this method, allows for personalized creations across materials such as textiles, plastics, and metals.

Applications of UV DTF Gangheet Printing

UV DTF Gangheet has found its niche in several industries, notably fashion and promotional items. This technology allows for the crafting of customized clothing like t-shirts and jackets, which are not only visually striking but also boast durability against wear and tear. The ability to print complex designs without compromising on quality opens up new avenues for fashion brands looking to create unique offerings.

Moreover, businesses leveraging UV DTF technology for promotional items enjoy not only aesthetic appeal but also longer-lasting products. Items such as branded mugs, tote bags, and keychains benefit from vibrant colors and resilient prints, effectively enhancing brand recognition. The versatility of substrates means that businesses can experiment with new merchandise types, leading to innovative marketing strategies and deeper customer engagement.

Trends and Innovations in UV DTF Gangheet

As industries further embrace UV DTF Gangheet, several trends have emerged that underscore its growth potential. Manufacturers are continuously seeking advancements in ink formulations to improve adhesion and color vibrancy. This focus on innovation ensures that the prints produced are not only visually appealing but also withstand the test of time in terms of appearance and durability.

Another significant trend is the expansion of suitable substrates for UV DTF printing. Researchers and developers are working to expand the materials compatible with direct-to-film applications, targeting items traditionally deemed difficult to print on. As these capabilities grow, the use of UV DTF in diverse sectors, from industrial applications to bespoke gift items, is likely to increase.

The Future of Custom Printing with UV DTF Technology

The future of custom printing with UV DTF technology looks promising, particularly as the demand for personalization and quick turnover rises among consumers. Businesses are increasingly adopting these modern printing methods to stand out in a crowded marketplace, with UV DTF providing a compelling combination of speed, quality, and flexibility. It allows brands to tap into consumer desires for unique and tailored products, creating opportunities for market differentiation.

Furthermore, as technology continues to progress, enhancements in printer capabilities and the precision of print heads will provide even finer resolution outputs. This means that UV DTF Gangheet will not only cater to current needs but also adapt to evolving design trends, embracing higher-quality standards and customer expectations across all sectors.

Frequently Asked Questions

What is UV DTF Gangheet and how does it work?

UV DTF Gangheet is an innovative printing method that combines UV printing technology with Direct to Film (DTF) techniques. It works by printing high-resolution designs onto a specialized film using UV inks, which cure instantly under ultraviolet light. This allows for durable and vivid prints on various materials, making it ideal for custom printing.

What are the benefits of using UV DTF Gangheet for custom printing?

The benefits of UV DTF Gangheet include faster production times due to instant UV ink curing, high-quality prints that offer vivid colors, reduced material waste through on-demand printing, and versatile substrate compatibility, allowing for prints on a wide range of materials.

Can UV DTF Gangheet be used for fabric printing?

Yes, UV DTF Gangheet is highly effective for fabric printing. It allows for the creation of custom-designed clothing items that are resistant to fading and wear, making it suitable for apparel such as t-shirts and jackets.

What types of products can be created using UV DTF Gangheet?

UV DTF Gangheet can be used to create a variety of products including clothing, promotional items like mugs and keychains, signage, displays, and custom gifts such as phone cases and photo frames, all featuring intricate designs and vibrant colors.

How does UV DTF Gangheet compare to traditional printing methods?

Unlike traditional printing methods, UV DTF Gangheet offers quicker turnaround times, superior print quality with vibrant colors, and less environmental impact due to reduced material waste and on-demand production. Additionally, UV DTF can print on a wider variety of substrates without extensive pre-treatment.

What recent advancements are being made in UV DTF Gangheet technology?

Recent advancements in UV DTF Gangheet technology include improvements in ink formulations for better adhesion and durability, expansion of substrate options suitable for printing, and advancements in printer technology leading to higher resolution and print quality, enhancing its versatility for various applications.

| Key Aspect | Details |

|---|---|

| Introduction | UV DTF Gangheet combines UV printing technology with Direct to Film methods for vibrant, durable prints. |

| Understanding UV DTF | Utilizes high-resolution designs printed on film with UV inks that cure under ultraviolet light, ensuring vividness and durability. |

| Workflow Steps | 1. Design Creation 2. Printing the Film 3. Transferring the Design 4. Finishing Touches |

| Advantages | – Faster production times – High-quality, vibrant prints – Reduced material waste – Versatile substrate compatibility |

| Applications | – Fashion and Apparel – Promotional Items – Signage and Displays – Custom Gifts |

| Recent Developments | – Improved ink formulations – Expanded substrate options – Increased print quality |

Summary

UV DTF Gangheet is transforming the landscape of modern printing by effectively merging UV technology with Direct to Film methods. This innovative approach allows for the production of striking designs on various materials through a streamlined workflow. With rapid curing inks and extensive substrate compatibility, UV DTF Gangheet ensures long-lasting quality while minimizing waste. The method demonstrates significant advantages, including faster production speeds and high-resolution outputs, making it ideal for diverse applications ranging from fashion to promotional merchandise. As technology continues to advance, the capabilities of UV DTF Gangheet promise to expand even further, establishing its pivotal role in the printing industry.