Direct-to-Film Printing: The Ultimate Beginner’s Guide

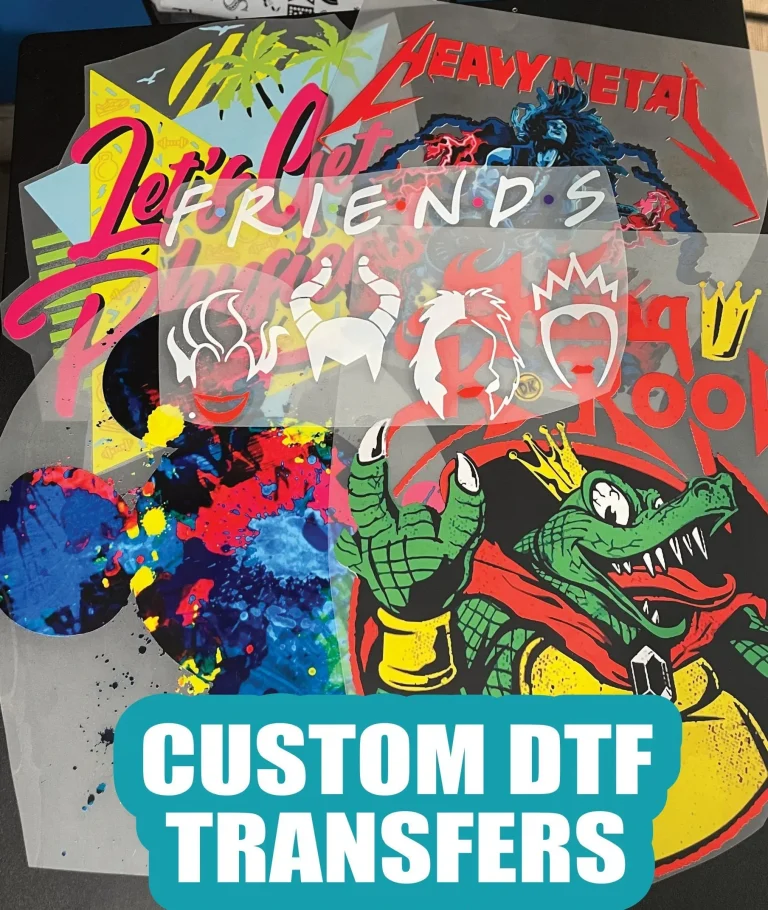

Direct-to-Film Printing is transforming how beginners and small businesses create customized apparel, offering vibrant designs with a soft hand and a forgiving workflow that lets newcomers experiment without a steep learning curve, while still delivering repeatable results, easy calibration, and the confidence to scale from hobby projects to small runs, which is especially valuable for home studios where space is limited and resources must be managed carefully.As you start out, you’ll likely hear terms like DTF supplies and DTF printing for beginners while selecting inks, films, and powders, mapping a realistic budget, comparing warranties, and planning your first tests, swatches, and sample garments to validate color, adhesion, and fabric compatibility, while it also helps you compare vendors and pick a kit that ships reliably within your target timeline.