The Georgia DTF Studio Tour offers a rare, real-world glimpse into the art and science of direct-to-film printing. Visitors see how designs move from digital files to finished garments, gaining insight into the DTF workflow and the choices that affect color, adhesion, and texture. This is not a marketing brochure; it’s an immersive look at the technology, workflows, and daily practices that define a professional DTF environment. As you move through the space, you’ll witness the evolution from concept to production, with emphasis on consistency, quality control, and workflow discipline. If you’re exploring apparel customization or brand printing, the tour explains how file preparation, equipment handling, and timing come together to deliver reliable, vibrant results.

Seen through a broader lens, this Georgia-based transfer-technology walkthrough illustrates how digital designs move from screen to fabric via a film carrier. Visitors learn the sequence—from optimization of artwork to substrate selection, curing steps, and final checks—described in terms that emphasize reliability and repeatability. The tour also calls out the practical equipment and safety practices that power a smooth production line, from printers and films to heat presses and ventilation. In short, this hands-on demonstration makes the principles behind modern textile transfer accessible, showing how a well-managed workflow yields durable, vibrant results. For designers and shop owners, the takeaway is clear: organize artwork, calibrate color, and standardize steps to translate ideas into consistent products.

How Direct-to-Film Printing Reshapes Textile Production

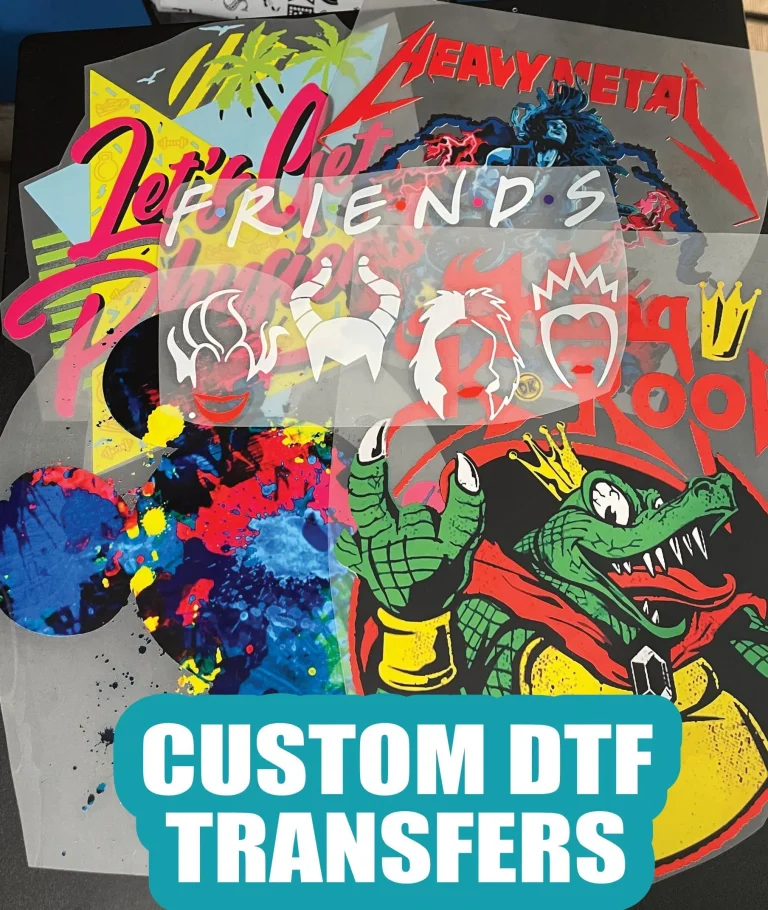

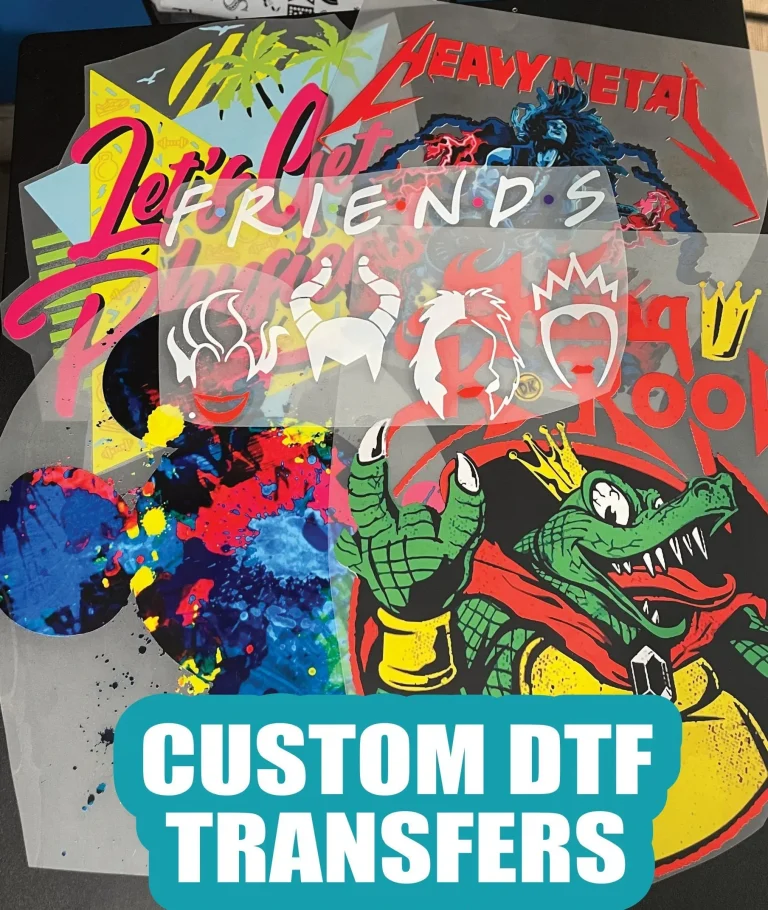

Direct-to-Film printing has transformed textile production by making high-fidelity designs accessible on multiple fabrics. In the DTF printing workflow, artwork is prepared, then printed onto a PET film using specialized printers and inks, delivering a wide color gamut and fine detail. The Georgia DTF Studio Tour offers a clear lens into this technology, showing how the basic building blocks—design, print, and transfer—come together to produce ready-to-wear or promotional items.

Because the process uses a transfer film and bonding powder, the production is adaptable for small runs and on-demand customization. The DTF printing process enables vibrant colors on cotton, blends, and synthetics, with durable adhesion after curing. Observers on the studio tour can trace each step from digital design to the finished print, appreciating how color management and substrate choice influence outcome.

Inside a Professional DTF Workshop: Workflow, Standards, and Precision

In a professional DTF workshop, workflow discipline matters as much as machine performance. You’ll find dedicated stations for design prep, film printing, powder application, heat pressing, and final quality checks—each with precise roles in the overall output. The environment demonstrates how a DTF printing equipment lineup is organized to optimize uptime and consistency.

Guided explanations reveal common terms such as white ink saturation, ICC profiles, and calibration routines. Standard operating procedures, checklists, and safety protocols help reduce errors and ensure predictable results across production runs, which is the core value of a true DTF workshop.

The DTF Printing Process: From Design to Transfer

From design to transfer, the DTF printing process unfolds as a carefully choreographed sequence. Designers prepare artwork with correct bleed and color settings, then print onto PET film using water-based or pigment inks suited for transfer. After printing, bonding powder is applied and cured, creating a cohesive layer ready to be transferred to fabric.

During the transfer phase, the film is aligned on the fabric and pressed under controlled heat and pressure, followed by a second curing step to lock the print. The Georgia DTF Studio Tour offers a hands-on view of how operators monitor color accuracy, perform test prints, and document each run to maintain consistency across batches.

Choosing the Right DTF Printing Equipment for Small Studios

Choosing the right DTF printing equipment for a small studio means balancing capability with cost and footprint. Consider a reliable DTF printer capable of crisp lines and strong color fidelity, paired with a dedicated curing station and a quality heat press. The equipment should support easy maintenance, spare parts access, and consumables such as bonding powder and PET film.

Additionally, assess software compatibility, workflow automation options, and service support. A considered setup reduces downtime and helps you scale from initial trials to small-batch production, aligning with the demands of a modern DTF studio or home-based operation.

Georgia DTF Studio Tour: A Real-World Look at DTF Practices

Georgia DTF Studio Tour: A Real-World Look at DTF Practices gives visitors an inside view of a functioning print shop. You’ll observe the end-to-end flow from file handling and color management to film printing, powder application, curing, and final transfer. The tour emphasizes how real-world constraints—materials, equipment limits, and operator skill—shape outcomes in direct-to-film printing.

This experience also highlights how a studio aligns processes with customer expectations, including consistent color reproduction, proper fabric compatibility, and efficient turnarounds. By seeing how a DTF workshop calibrates printers, manages workflows, and documents every run, designers and entrepreneurs gain practical insights into running a successful DTF printing operation.

Quality Control, Safety, and Best Practices in DTF Studios

Quality Control in DTF Studios centers on repeatability and accurate color reproduction. Operators compare prints to color targets, inspect edge detail, and test wash performance under standardized conditions. A robust workflow minimizes defects and relies on repeatable steps, calibration checks, and poka-yoke-like reminders to catch misalignments early.

Safety and environmental considerations are integral to daily practice. You’ll learn about proper ventilation, powder handling, solvent management, and waste disposal in a professional DTF workshop. Understanding how these factors interact with DTF printing equipment helps ensure both worker safety and long-term production reliability.

Frequently Asked Questions

What is the Georgia DTF Studio Tour?

The Georgia DTF Studio Tour offers a real-world look at direct-to-film printing in a professional DTF workshop. You’ll observe the full workflow—from design to finish—and learn how color management, curing, and quality control contribute to durable, vibrant prints.

During the Georgia DTF Studio Tour, how does the DTF printing process work?

The tour highlights the DTF printing process steps: file preparation, printing onto PET film with special inks, applying and curing bonding powder, transferring to fabric, and final curing. You’ll see how hardware and software cooperate to achieve consistent results.

What DTF printing equipment will you see on the Georgia DTF Studio Tour?

Expect to see high-end DTF printers, curing stations, heat presses, and supporting equipment. Guides explain each tool’s role in consistency, calibration, and throughput, showing how equipment impacts final quality.

Is the Georgia DTF Studio Tour suitable for beginners or designers new to DTF?

Yes. The tour is educational, illustrating file prep, substrate choices, color management, and the end-to-end workflow, helping newcomers understand how a DTF workshop operates and how decisions affect results.

What safety and quality-control practices are shown on the Georgia DTF Studio Tour?

The tour emphasizes safety gear, ventilation and waste handling, and standard operating procedures in a professional DTF workshop. You’ll also see quality-control steps like color targets and wash tests that ensure durability.

How can attending the Georgia DTF Studio Tour benefit my design business or workflow?

You’ll gain practical takeaways on artwork preparation, fabric choices, production timelines, and communicating with a DTF studio. The tour demonstrates the DTF printing process in action and how a well-run DTF workshop maintains consistency.

| Topic | Key Points |

|---|---|

| Introduction |

|

| What is Direct-to-Film (DTF) Printing? |

|

| Inside a Professional DTF Workshop: What to Expect on the Tour |

|

| Direct-to-Film Printing: The Core Technology and Its Role in Modern Textiles |

|

| DTF Studio Tour Essentials: Equipment, Workflow, and Quality Assurance |

|

| From Design to Delivery: The DTF Printing Process in Practice |

|

| Materials, Tools, and Safety Considerations |

|

| Quality Control: What Keeps Prints Consistent |

|

| DTF vs. Other Methods: Why Teams Choose Direct-to-Film |

|

| Practical Takeaways for Designers and Entrepreneurs |

|

Summary

Georgia DTF Studio Tour offers a comprehensive, hands-on look at the professional Direct-to-Film workshop environment. By observing the complete ecosystem—from design and printing to curing, transfer, and quality control—you gain a clear understanding of how to deliver consistent, high-quality results. The tour emphasizes the importance of standardized workflows, precise color management, and careful material selection in achieving durable, vibrant prints. Whether you are a designer exploring new customization options, a business owner evaluating production methods, or simply curious about the technology, this kind of hands-on experience demystifies direct-to-film printing and showcases why DTF has become a popular choice in modern textile production. In sum, the Georgia DTF Studio Tour is not just a tour; it’s an education in process, quality, and practical creativity. You will leave with a better sense of how a professional DTF workshop operates, the tools that power the process, and the steps necessary to translate digital designs into tangible, lasting prints. For anyone considering adopting DTF in their own practice, the lessons learned on a studio tour can shorten the learning curve and inspire clever approaches to design, production, and customer satisfaction.