In the ever-evolving world of apparel and fabric printing, DTF vs Screen Printing has become a hot topic among businesses seeking the best method for their needs. As technology continues to advance, the discussion surrounding DTF printing benefits and its ability to produce high-quality prints is gaining traction. Screen printing vs DTF highlights the distinct characteristics of each method, providing clarity for those unsure which aligns with their objectives. While the cost of DTF printing can be more manageable for small businesses, screen printing advantages often lie in its durability and traditional appeal. This guide will dive deep into the nuances of these two approaches, equipping you with the information necessary to make an informed choice.

When considering options between two popular techniques for fabric printing, the contrast between Direct to Film (DTF) technology and classic screen printing methods is prominent. The evolution of these printing styles introduces varied benefits and challenges, making it crucial for businesses to analyze their unique requirements. Each technique carries its own strengths, influencing factors such as production speed, quality, and cost-effectiveness. DTF and screen printing both offer distinctive solutions, catering to different market demands and types of projects. By exploring these alternative terms, we can better understand the implications and suitability of each printing method for diverse applications.

Introduction to DTF Printing

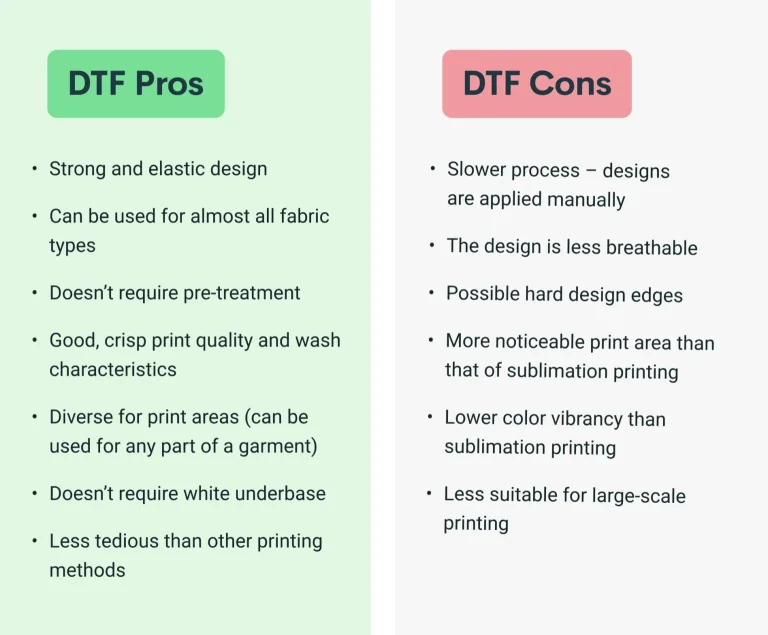

DTF printing, or Direct to Film printing, is a revolutionary technique that has transformed the apparel decoration landscape. Utilizing specialized films and high-quality inks, DTF allows for stunning designs that can be transferred onto a wide variety of fabrics. This method has gained popularity due to its ability to produce intricate patterns, vibrant colors, and the flexibility of printing on multiple fabric types, including cotton, polyester, and blends. Many businesses are now recognizing DTF printing benefits such as quicker turnaround times and minimal setup costs, making it increasingly attractive for small to medium enterprises.

One of the significant aspects of DTF printing is its compatibility with a wide range of fabrics. Unlike traditional methods that often restrict choice, DTF technology empowers designers to explore creative avenues without constraints. Moreover, the ongoing developments in DTF technology, such as high-resolution prints and enhanced durability, further establish its reputation as a leading solution in the fabric printing market.

Screen Printing Advantages

Screen printing remains a stalwart in the printing industry, primarily due to its robustness and the rich texture it brings to printed designs. The process is known for creating vibrant colors that stand out, especially on larger orders where economies of scale can drive costs down significantly. This method excels in producing bold designs that are durable and can withstand numerous washes without fading, making it a preferred choice for promotional gear and custom apparel.

However, screen printing’s advantages are coupled with some limitations. The setup costs can be significantly higher than those of DTF printing, as creating screens for each design is labor-intensive and requires time. For businesses that rely heavily on versatility, DTF may present an attractive alternative that combines quality with reduced lead times and lower costs.

DTF Printing Quality Compared to Screen Printing

The quality of the print is paramount when choosing a method, and DTF printing has garnered a reputation for its high fidelity and detail reproduction. DTF printing quality is often superior when it comes to complex designs featuring gradients or multiple colors. This technique captures intricate details and maintains consistency across prints, ensuring that each piece looks professional and refined. Customers can expect a pristine finish without compromising on durability.

In contrast, screen printing can struggle with fine detail, especially when intricate images and designs are involved. While it holds its ground for bold, graphic prints, the layering process involved may limit the color range and intricate details that can be achieved. Thus, for businesses that prioritize intricate and colorful customization, DTF printing stands out as a reliable choice.

The Cost of DTF Printing

Understanding the cost of DTF printing is vital for any business deliberating between it and screen printing. DTF technology typically offers a more budget-friendly entry point. The equipment required has seen substantial reductions in price and size, balancing the cost of initial investment against operational efficiency. This accessibility enables smaller businesses to produce quality prints without incurring overwhelming expenses.

On the other hand, the cost structure of screen printing can be complex, mostly due to the setup required for each new project. While the per-unit cost can be lower for high-volume orders, the initial setup can be a barrier for startups or small businesses. Hence, understanding these cost dynamics is essential for businesses looking to maximize profitability while maintaining quality.

Speed and Efficiency Benefits of DTF Printing

In today’s fast-paced market, speed and efficiency are critical, and DTF printing is built to excel in these areas. The streamlined process allows for rapid production without sacrificing quality, which can be a game-changer for businesses needing to meet tight deadlines. As technology continues to improve, the turnaround time for DTF printing diminishes, providing an edge over traditional methods.

In contrast, screen printing often involves significant setup time. Each new design requires the creation of new screens, which can be time-consuming and often delays order fulfillment. For businesses that thrive on prompt service, DTF printing presents a clear advantage that can lead to enhanced customer satisfaction and potentially drive repeat business.

Choosing the Right Method: DTF vs Screen Printing

When it comes to making a decision between DTF vs Screen Printing, understanding the specific needs of your business is crucial. DTF printing shines in its versatility, catering to small order quantities and a variety of fabric choices without the need for extensive setup time. Its ability to deliver high-quality, detailed prints makes it ideal for custom work and unique designs.

On the other hand, businesses with substantial order volumes may still favor the cost-effectiveness of screen printing for larger runs despite its higher initial setup costs. Ultimately, the choice between DTF and screen printing will hinge on your production needs, desired print quality, and budget, ensuring a match that aligns with your business strategy.

Frequently Asked Questions

What are the key DTF printing benefits compared to screen printing?

DTF printing offers several benefits over traditional screen printing, including lower upfront investment costs, high-quality prints with vibrant colors, and versatility across various fabric types. Additionally, DTF printing allows for quick turnaround times and is ideal for intricate designs, making it a favorable choice for small to medium businesses.

How does screen printing compare to DTF printing in terms of cost?

The cost of DTF printing is often lower than screen printing, especially for small runs, due to decreased initial equipment costs and streamlined production processes. Screen printing, while potentially cheaper for larger quantities, requires higher upfront investments which can be a barrier for smaller businesses.

What is the quality difference between DTF printing and screen printing?

DTF printing is known for its superior quality, allowing for high-fidelity prints with intricate details and vivid colors on various fabrics. While screen printing provides durability and is effective for larger batch productions, it may struggle with fine details and multiple color designs compared to DTF.

What are some advantages of screen printing over DTF?

Screen printing advantages include its ability to produce durable prints that are well-suited for high-volume orders, especially on cotton fabrics. It also excels with larger color blocks and simpler designs, providing a cost-effective option for bulk production despite higher upfront costs.

Is DTF printing a suitable option for small businesses?

Yes, DTF printing is increasingly becoming a suitable option for small businesses due to its lower cost, ease of use, and flexibility in producing diverse and high-quality prints without significant investment in equipment.

How do turnaround times compare between DTF and screen printing?

DTF printing typically offers shorter turnaround times than screen printing due to advancements in technology and streamlined production processes. Screen printing often involves longer setup times, which can delay order fulfillment, making DTF a more efficient choice for quick service.

| Aspect | DTF Printing | Screen Printing |

|---|---|---|

| Cost | Lower upfront costs; accessible to small businesses with compact printers. | Higher initial investments; setup costs can limit small operations. |

| Quality | Produces high-fidelity prints; versatile for various fabrics and intricate designs. | Durable, but less suited for complex designs; best for larger batches with fewer colors. |

| Speed | Faster turnaround times due to advanced technology and streamlined processes. | Longer setup times; potential delays due to stencil creation. |

| Market Developments | Recent advancements and investments enhancing accessibility and efficiency. | Established method but limited by high costs and setup requirements. |

Summary

DTF vs Screen Printing is a critical decision for businesses venturing into fabric printing, as both methods offer unique advantages. DTF printing has established itself as a flexible and accessible option, especially beneficial for small businesses looking to produce high-quality and intricate designs efficiently. Recent developments in DTF technology reflect its growing presence in the market, offering rapid turnaround times and lower costs, making it a competitive alternative to traditional screen printing. As the industry evolves, understanding the nuances of each method will empower businesses to choose the best printing solution tailored to their operational needs.