When considering custom fabric printing, the debate around DTF vs HTV vs Sublimation often takes center stage among creators and businesses alike. Each printing technology—DTF or Direct to Film, HTV or Heat Transfer Vinyl, and sublimation printing—provides distinct advantages tailored to specific needs. As you navigate through these options, understanding their unique features will equip you to determine the best printing method for your projects. Whether you’re aiming for vibrant colors, durability, or ease of use, this article will explore each method’s capabilities, helping you make informed decisions for your creative endeavors. From apparel to accessories, the right choice can elevate your designs to the next level.

In the realm of personalized printing, the terms Direct to Film (DTF), Heat Transfer Vinyl (HTV), and dye-sublimation are frequently mentioned as viable techniques for crafting custom designs. Whether you refer to these processes by their common names or delve into their technical specifics, knowing their strengths and drawbacks can significantly impact your project outcomes. Each technique has a different approach to fabric decoration—ranging from the transfer of vinyl sheets to the sublimation of dye into fabric fibers, thus making understanding their functionalities essential. Hobbyists and professionals alike must consider various factors, including material compatibility and design complexity, before settling on an ideal method. By unpacking these terms further, we aim to clarify your options for your next creative venture.

Understanding DTF Printing: A Deep Dive

DTF printing, or Direct to Film printing, has emerged as a favored choice among crafters and small-scale businesses alike, primarily due to its straightforward approach and impressive output quality. This method involves applying ink to a specific film which is then transferred to the desired fabric through heat application, resulting in vibrant and durable designs. Its growing popularity in the custom fabric printing market indicates a clear preference for technology that provides versatility and quality, catering to both small-scale projects and larger commercial applications.

One of the standout features of DTF printing is its ability to work on a wide variety of materials—from cotton and polyester to their blends—setting it apart as an adaptable option. This adaptability ensures that users can create custom products that range from athletic wear to decorative items like bags and home textiles. Furthermore, the moisture-wicking qualities inherent in polyester fabrics enhance the prints’ longevity, making DTF a practical choice for daily-use apparel.

HTV Printing for Beginners: A Simple Yet Effective Choice

Heat Transfer Vinyl (HTV) printing is often hailed as one of the easiest methods to dive into the world of custom fabric decoration. The process involves cutting designs from sheets of colored vinyl and then applying them to fabric surfaces with a heat press. This simplicity makes HTV a fantastic option for newcomers to custom printing, as it requires relatively minimal investment and technical skill relative to other methods.

HTV is particularly effective for creating straightforward designs—such as logos or texts—on t-shirts and bags, where crisp and defined edges are paramount. However, its limitations become apparent when dealing with more complex graphic artwork or materials that require a softer touch. While HTV adheres well to cotton and polyester blends, it may struggle to stick onto stretchy fabrics, presenting challenges to users looking to produce intricate designs or work with unconventional materials.

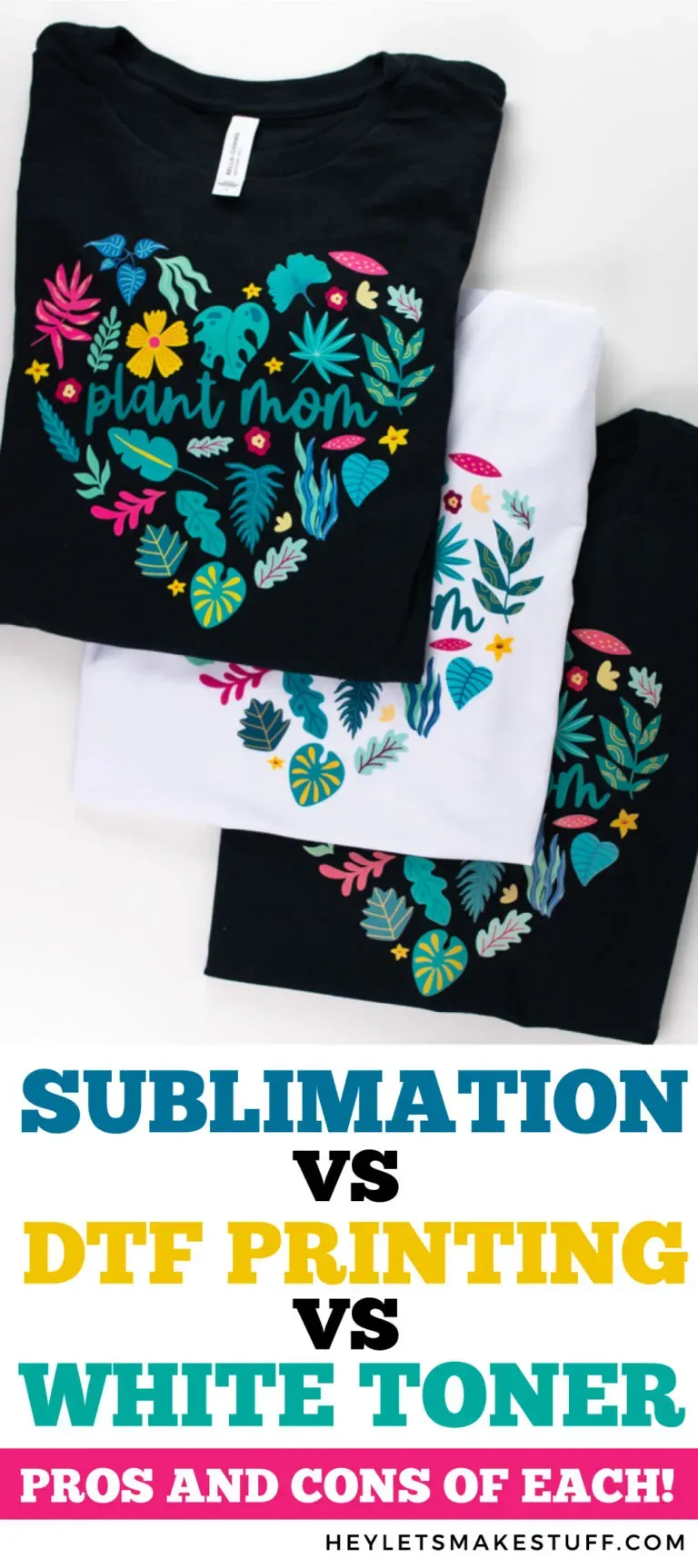

Sublimation Printing: Achieving Permanent Impressions

Sublimation printing stands out in the realm of fabric decoration due to its unique technique that allows dyes to become part of the material, embedding themselves within polyester fibers. This process not only delivers stunning, full-color images but also ensures that the designs are long-lasting and can withstand the rigors of washing without fading, cracking, or peeling. This distinctive feature makes sublimation ideal for sportswear, promotional items, and any application where durability and color vibrancy are paramount.

However, sublimation has its own set of limitations. It works best on high polyester content materials and is ineffective on dark or non-polyester substrates. This requires users to be selective about their material choices, often steering them towards specific fabric types that can accommodate this method. Despite these constraints, the quality that sublimation achieves makes it an unbeatable option for certain products, especially those intended for high-volume use.

DTF vs HTV vs Sublimation: Finding Your Best Match

When comparing DTF, HTV, and sublimation printing, the best choice largely depends on the specific needs of your project. DTF printing shines in versatility, allowing for a wide range of materials and complex designs while maintaining vibrant colors and durability. This makes it an exceptional option for users like small business owners who require flexibility in their products and may cater to various customer needs.

HTV offers an affordable entry point for beginners focused on simple and quicker projects. Basic shapes and logos can be created with ease, making HTV an excellent choice for crafting personalized gifts or promotional materials. Meanwhile, sublimation suits those targeting high-quality outputs for polyester surfaces and looking to produce work that has a professional finish and longevity. Understanding each method’s strengths and weaknesses can greatly influence the success of your custom printing endeavors.

Comparing Durability Across Printing Techniques

Durability is a crucial factor to consider when choosing between DTF, HTV, and sublimation printing methods, as it impacts the longevity and appearance of your finished products. DTF printing is celebrated for producing resilient designs that remain vibrant, even after numerous washes. The prints are flexible, adhering well to the fabric without cracking, which is indispensable for apparel that experiences regular wear and tear.

On the other hand, HTV, while also durable, may not provide the same level of wash resilience as DTF, particularly if applied to commonly problematic fabrics. HTV can feel heavier on lightweight textiles, potentially impacting user comfort, especially in athletic applications. Meanwhile, sublimated designs are known for their exceptional durability as the ink directly integrates into the polyester fibers, offering a smooth feel and resistance to everyday wear. The choice in printing technique will ultimately hinge on how important performance and durability are for the intended application.

Making the Right Decision for Your Projects

Ultimately, selecting the best printing method among DTF, HTV, and sublimation boils down to understanding your project’s priorities. If you prioritize versatility and adaptability across multiple fabric types, DTF printing is your best bet. This method not only encompasses a range of materials but also caters to a diverse audience, making it suitable for various custom designs.

Conversely, for straightforward designs or for those just starting out, HTV offers ease of use and affordability without a steep learning curve. For high-quality, professional-grade prints on polyester items, sublimation reigns supreme, making it the go-to choice for sportswear or personalized merchandise. Weighing these aspects will aid you in making an informed decision, ensuring that your custom printing projects meet your expectations and stand out in quality.

Frequently Asked Questions

What are the main differences between DTF printing, HTV printing, and sublimation printing?

DTF printing uses a film for transferring designs onto various materials, HTV printing involves cutting vinyl and applying it to fabrics with heat, and sublimation printing embeds dye into polyester fabrics. Each method has its own strengths regarding material compatibility and design quality.

Which is the best printing method for versatile projects: DTF vs HTV vs Sublimation?

For versatility, DTF printing is the best choice. It works well on multiple fabric types, including cotton, polyester, and blends, making it suitable for a variety of projects compared to HTV and sublimation printing.

Can I use DTF printing on all fabric types, unlike HTV or sublimation?

Yes, DTF printing is compatible with a wide range of fabrics, including cotton and polyester blends, unlike HTV which has limitations with certain materials, and sublimation which only works well on high polyester content fabrics.

What are the durability differences between DTF, HTV, and sublimation printing?

DTF and sublimation printing provide durable prints that resist fading and cracking, while HTV, although durable, can feel heavier on the fabric. Sublimation offers a soft finish since the dye becomes part of the fabric.

Is DTF printing cost-effective compared to HTV and sublimation for custom fabric printing?

While DTF printing may have higher initial setup costs, it is cost-effective for larger projects due to its versatility. HTV is generally more affordable for simple designs, and sublimation is ideal when focusing on high-quality prints.

What is the best method for high-quality designs on polyester fabrics: DTF, HTV, or sublimation?

Sublimation printing is the best method for high-quality designs on polyester fabrics, as it embeds ink directly into the material, resulting in vibrant, permanent designs that will not crack or peel.

| Method | Description | Material Compatibility | Durability | Best For |

|---|---|---|---|---|

| DTF | Printing designs onto a film that is heat-pressed onto materials. | Compatible with cotton, polyester, and blends. | High durability and vibrancy even after washing. | Versatile projects including t-shirts and home decor. |

| HTV | Cutting designs from vinyl sheets and applying them with heat. | Works best with cotton and polyester blends. | Durable but can feel heavy due to vinyl material. | Cost-effective for simple designs on a budget. |

| Sublimation | Using heat to embed dye into polyester or polymer-coated surfaces. | Primarily on high polyester content items like sportswear. | Permanent finish that won’t crack or peel. | Professional quality, ideal for specific fabrics. |

Summary

DTF vs HTV vs Sublimation are three distinct methods of customizing fabric that serve different needs and applications. Each technique has its own set of advantages and limitations crucial to consider when choosing the best fit for your projects. DTF is celebrated for its versatility and broad material compatibility, allowing for vibrant and durable images on a variety of fabrics. Conversely, HTV shines in simplicity and affordability, making it an excellent choice for quick projects but may feel heavy on certain fabrics. On the other hand, sublimation delivers exceptional quality on polyester items, embedding designs to create a soft, permanent finish, suitable for high-wear applications like sportswear. Understanding the specific benefits of DTF vs HTV vs Sublimation will guide you in selecting the appropriate method for your individual crafting or business needs.