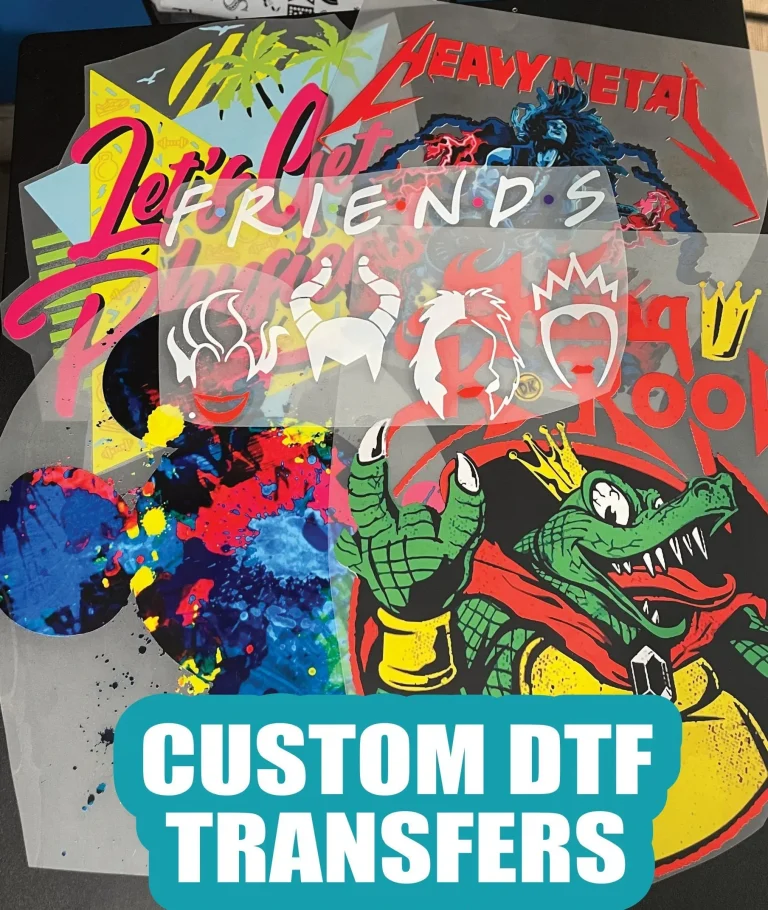

DTF transfers have exploded onto the scene as a versatile method for decorating apparel, delivering vibrant color, sharp detail, and easy customization. When you’re deciding how to print designs on clothing, it’s common to compare DTF transfers vs screen printing. Each method has its strengths and trade-offs, and understanding these nuances helps you see the DTF transfers benefits as well as when screen printing may be preferable. For many shops, cost and workflow considerations matter, including DTF transfer cost and the setup differences between methods. Whether you’re starting a small apparel line or expanding an on-demand business, a solid grasp of how DTF transfers compare to screen printing vs DTF informs your design decisions.

In practical terms, this film-based method for garment decoration involves printing onto a transfer sheet, applying an under-base, and transferring artwork onto fabric with heat. When comparing these digital-to-fabric options with traditional screen-print approaches, the emphasis shifts to flexibility, turnaround, and the ability to handle complex multi-color designs. Other terms you might encounter—such as direct-to-film transfers, heat-press decoration, and print-on-film techniques—align with the same core concept of transferring artwork from a prepared sheet to apparel. For brands exploring custom apparel printing methods, recognizing the different workflows helps you plan inventory, pricing, and supplier selection while keeping quality consistent. So, whether you call it a film transfer system, digital heat transfer, or a DTF-like process, the goal remains the same: vibrant, durable prints that can be produced on demand.

DTF Transfers vs Screen Printing: Choosing the Right Custom Apparel Printing Method

DTF transfers vs screen printing is a central consideration for brands deciding how to decorate apparel. If your designs rely on intricate details, vibrant color blends, or photography-like imagery, DTF transfers offer a compelling path, especially for small to mid-size runs and on-demand orders. In contrast, screen printing shines when you need bold, solid colors across large quantities, with strong durability on cotton-heavy fabrics. By weighing these two approaches against your design complexity, production capacity, and turnaround goals, you can select a method that aligns with your product strategy and budget.

From a practical standpoint, the decision often centers on the design file, substrate options, and cost structure. The phrase DTF transfers vs screen printing captures the idea that each method has its niche: DTF transfers are praised for high detail and flexible substrate compatibility, while screen printing is renowned for low per-unit costs in bulk. This comparison also touches on the broader landscape of custom apparel printing methods, helping you plan for future lines, variations, and limited editions without sacrificing efficiency.

DTF Transfers Benefits and Cost Considerations for Small Runs and On-Demand Orders

DTF transfers benefits are evident in their ability to reproduce complex artwork with smooth gradients and fine text, even on a variety of fabrics. The approach supports white underbases on dark fabrics, expanding what you can achieve without multiple setup steps. For brands focusing on customization or limited releases, these advantages translate into faster changeovers, reduced inventory risk, and the flexibility to offer on-demand products without committing to large screen-print runs.

When evaluating DTF transfer cost and overall value, consider how per-unit economics shift with order size and design changes. DTF does not require a new screen for each color, which can lower upfront setup costs compared to traditional screen printing in small batches. However, you should also weigh substrate compatibility, curing requirements, and adhesive performance. For many shops, the cost dynamics favor DTF transfers for small to mid-sized runs and design iterations, while screen printing may still win on price per unit for very large volumes or straightforward graphics.

Frequently Asked Questions

DTF transfers vs screen printing for custom apparel printing methods: which option should you choose?

DTF transfers vs screen printing is a common consideration for custom apparel printing methods. For small to mid-size runs and designs with high detail or many colors, DTF transfers benefits include vibrant color, fine gradients, and quick setup without per-color screens. Screen printing, on the other hand, excels in large-volume runs with bold, solid colors and proven durability on cotton-heavy fabrics. If you need rapid turnarounds or customization, DTF transfers offer flexibility; if you’re producing large quantities of the same design, screen printing typically delivers lower per-unit costs and a straightforward workflow.

Is the DTF transfer cost justified by the DTF transfers benefits, especially when compared to screen printing?

DTF transfer cost is often justified by its benefits in on-demand or small-to-mid runs, complex multicolor imagery, and the ability to print on a wide range of fabrics, including dark garments with a white underbase. The main cost factors are the transfer film, adhesive powder, and equipment, rather than per-color screens. For very large runs, screen printing can offer a lower per-unit cost due to screen amortization and ink efficiency. In short, if you need high detail, customization, and flexible production, DTF transfers benefits usually outweigh the costs; for bulk, simple designs, screen printing may be more cost-efficient.

| Aspect | DTF transfers | Screen printing |

|---|---|---|

| Process overview | DTF: Print artwork onto a clear transfer film using CMYK (often with white); apply a finishing powder, cure, and then transfer the image to fabric with heat. | Screen printing: Create a stencil (screen) for each color and press ink through the screens onto the fabric; cure the ink. |

| Best use / Strengths | Detailed, multicolor designs; small runs; on-demand; white underbase for dark fabrics. | Large runs; bold, solid colors; durable on cotton; high per-unit efficiency for bulk. |

| Key benefits | High detail and color richness; versatile on fabrics; no per-color screens; white ink on dark fabrics; quick setup for small batches. | Cost-efficient for large runs; strong durable prints; high production speed for bulk; bright colors on light fabrics. |

| Feel & durability | Often softer hand; adhesion and curing quality influence hand. | Heavier feel; ink sits on surface; can be textured, especially with opaque white on dark fabrics. |

| Cost & turnaround | Lower upfront for setup; good for small/mid runs; fast changeovers. | Higher upfront (screens, emulsions); cheaper per unit for large runs; fastest bulk production. |

| Design versatility | High-resolution imagery, gradients, and subtle shading; white underbase supports full color on dark fabrics. | Bold, saturated colors; efficient for simple or multi-color designs; scalable for bulk runs. |

| Materials & care | Works on cotton, blends, and some synthetics; adhesion depends on fabric and care. | Ink sits on fibers; curing is essential; care guidelines depend on inks and substrates. |

| Sustainability | Film transfers and powders; disposal considerations; eco options vary by supplier. | Water-based inks are common; environmental footprint tied to ink chemistry and disposal. |

| When to choose | Small to mid-sized runs; rapid design changes; complex multicolor designs or on-demand orders. | Large-volume orders; simple/solid-color designs; price-sensitive bulk production. |

| Practical tips | File prep: high-resolution; plan white underbase for dark fabrics; pre-treat; use a reliable heat press; test on fabrics; QA. | File prep: accurate color separations; plan for underbase and ink bleed; fabric prep; ensure proper curing; test and QA. |

Summary

DTF transfers offer a flexible option for modern apparel printing, delivering high-detail images with rapid turnarounds and customization. Screen printing remains unbeatable for large-volume orders and bold, solid-color designs on cotton-heavy fabrics, but DTF transfers provide compelling advantages for small batches, complex graphics, and on-demand production. By weighing the strengths, trade-offs, and practical tips outlined here, brands can choose DTF transfers, screen printing, or a hybrid approach to optimize workflow, production efficiency, and profitability. The key is to test across fabrics, maintain quality control, and align your method with market needs to deliver vibrant, durable apparel.