DTF transfers vs screen printing is a hot topic for designers and shop owners weighing quality, cost, and speed. This guide compares how each method affects outcomes like color fidelity, setup time, and the durability of printed shirts. DTF transfers offer vibrant, detailed images and versatility across fabrics, while screen printing delivers bold colors and proven long-term durability. Understanding the pros and cons of DTF transfers and screen printing helps you decide on initial investments, DTF vs screen printing cost, per-unit costs, and production timelines. By weighing run size, artwork complexity, and budget, you’ll choose the method that best fits your designs and business goals.

Beyond these terms, many pros refer to the modern film-to-fabric approach as digital-to-film transfers and to the traditional option as mesh-screen printing. Alternative descriptors include heat-transfer film versus ink deposition through screens, or film-based color transfer compared with stencil-based imprints. Following LSI principles, it helps to map related ideas such as color fidelity, production speed, fabric compatibility, and the perceived hand feel. In practice, buyers weigh how these methods handle complex imagery, repeatable results, and durability across fabrics. Using related concepts like dye-sub alternatives, print durability, and scalability, you gain a broader intuition for choosing the best garment decoration method.

DTF transfers vs screen printing: cost considerations, durability, and hand feel

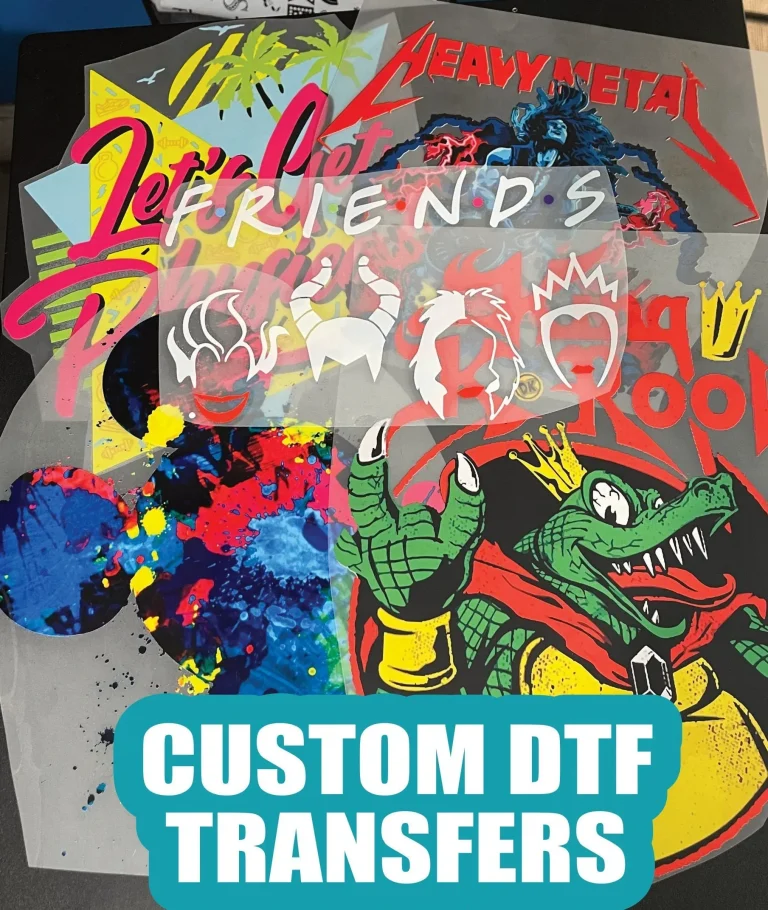

DTF transfers vs screen printing is a core debate for teams and shops weighing cost, quality, and turnaround. When evaluating the DTF vs screen printing cost, small runs often favor DTF because there’s no need to invest in multiple screens, and artwork changes come with minimal rework. The result can be a lower barrier to entry for custom designs, one-offs, and limited editions, while still delivering vibrant color and gradient detail through DTF transfers.

For larger runs, screen printing tends to lower the cost per unit as volume grows, thanks to the efficiency of mass-produced screens and inks. Durability of printed shirts also tends to be very high when the printing process is executed correctly, with heavy or specialty inks providing long-lasting results on a wide range of fabrics. In short, DTF transfers excel in flexibility and fast turnarounds, while screen printing shines in scale and long-term cost efficiency.

DTF transfers vs screen printing: practical guidance for choosing by design and production size

Design complexity and print area significantly influence which method makes sense. DTF transfers offer strong color reproduction and the ability to reproduce fine gradients, which benefits highly detailed artwork and photographic images. Because they don’t require multiple screens, the design can be adjusted quickly, reinforcing the idea that DTF is well suited for small batch runs or designs that require frequent iteration.

In contrast, screen printing’s strength lies in bold, opaque colors and durable results for larger quantities. When your design is simple or uses a limited palette, screen printing can deliver excellent durability of printed shirts at a lower per-unit cost in high volumes. The right choice depends on your artwork, target fabrics, and expected production size.

Frequently Asked Questions

DTF transfers vs screen printing: how does the ‘DTF vs screen printing cost’ scale from small to large runs?

Costs depend on run size and design. Small runs (1–25 shirts): DTF transfers often offer a lower cost per unit because there are no screens to create. Medium runs (25–200 shirts): DTF can remain competitive for detailed, multi‑color artwork, while simpler designs may start showing cost advantages for screen printing as volume grows. Large runs (200+ shirts): Screen printing typically provides the lowest per‑shirt cost due to economies of scale, once the upfront screen investment is covered. Other factors to weigh include lead times, inventory needs, and consumables. In short: for small runs, DTF is often cheaper; for large runs, screen printing usually wins on cost.

DTF transfers vs screen printing: what are the pros and cons of DTF transfers for the durability of printed shirts compared with screen printing?

Pros of DTF transfers include strong color reproduction, flexibility across fabrics, a soft hand, and low setup for small runs, making it ideal for detailed artwork. Cons include longer setup steps for certain workflows and potential higher per‑unit costs at very large volumes, plus durability that hinges on proper curing and washing. In terms of durability of printed shirts, screen printing generally offers exceptional wash durability when cured correctly, while DTF can be very durable too if heat pressing and curing are done properly. For long‑lasting results, many shops match the method to the design: use screen printing for large, simple color blocks and DTF transfers for detailed, multi‑color designs or small runs, ensuring proper process control to maximize longevity.

| Aspect | DTF Transfers | Screen Printing |

|---|---|---|

| What it is | Direct-to-film process: prints design on specialized film, adds bonding powder, cures, then transfers with heat to fabric; results in vibrant color and soft hand, versatile across fabrics (including dark garments). | Classic method that pushes ink through a mesh screen with a squeegee; each color typically needs its own screen; produces bold, opaque color and strong durability on many materials. |

| Typical strengths | Strong color reproduction and detail; fabric versatility; favorable for small runs; soft hand; easy design changes without retooling screens. | Durability and ease of large runs; cost efficiency at scale after screens are created; bold colors; established process with a large ecosystem. |

| Common drawbacks | Longer setup for some workflows; per-unit cost can rise with very high volumes; durability depends on proper curing. | High upfront setup for small runs; less flexible for highly detailed designs; potential heavier hand depending on ink and fabric. |

| Cost by run size | Small runs (1–25) often cheaper per unit due to no screens and easy changes; good for personalization. | Large runs (200+) usually cheaper per unit due to economies of scale; screens and setup amortized over many units. |

| Lead time / speed | Often faster for small orders and proofs; fewer setup steps than multi-color screens. | Longer lead times for setup; excels in predictable, long-run production. |

| Best use cases | Small batches, highly detailed artwork, personalization, quick turnarounds; works well on dark fabrics. | Large batches, simple or bold color palettes; high durability requirements; cost efficiency at scale. |

| Implementation tips | Invest in quality transfer film, reliable curing equipment, accurate heat press calibration; pre-treat fabrics per supplier guidance. | Establish clean workflow for image separation, proper emulsions and mesh counts; test on similar fabrics and inks to refine color matching. |

| Common myths | Hand feel can be very soft with proper settings; durability depends on curing and washing conditions. | Screen printing is always cheaper for large runs; not always—complex, multi-color designs can incur higher setup costs. |

| Bottom line takeaway | DTF transfers offer flexibility and speed for small runs and detailed artwork with a soft hand; great for customization. | Screen printing shines for large-volume production, cost efficiency at scale, and durable, bold prints on a wide range of materials. |

Summary

Conclusion: DTF transfers vs screen printing is not a one-size-fits-all decision. The best choice depends on your specific workflow, order size, and design requirements. DTF transfers shine for smaller runs, intricate artwork, and quick turnarounds with a soft hand, while screen printing excels in large-scale production, color consistency, and long-term durability for straightforward designs. By understanding the strengths and limitations of each method, you can tailor your print strategy to meet customer needs, control costs, and meet timelines. A thoughtful approach may even blend both methods to leverage the advantages of each for your apparel projects.