DTF Transfers, or Direct-to-Film transfers, have revolutionized the custom apparel printing landscape. As more businesses embrace this innovative DTF printing technology, understanding its advantages and limitations becomes crucial for making informed decisions. This printing method stands out for its ability to produce vibrant, high-quality designs on various fabric types, making it an ideal choice for garment decoration. In contrast to traditional DTG printing, DTF Transfers offer lower costs and faster turnaround times, opening doors for small businesses and artists alike. As the demand for personalized products continues to grow, exploring the unique features of DTF Transfers can help you carve a niche in the competitive market of custom apparel printing.

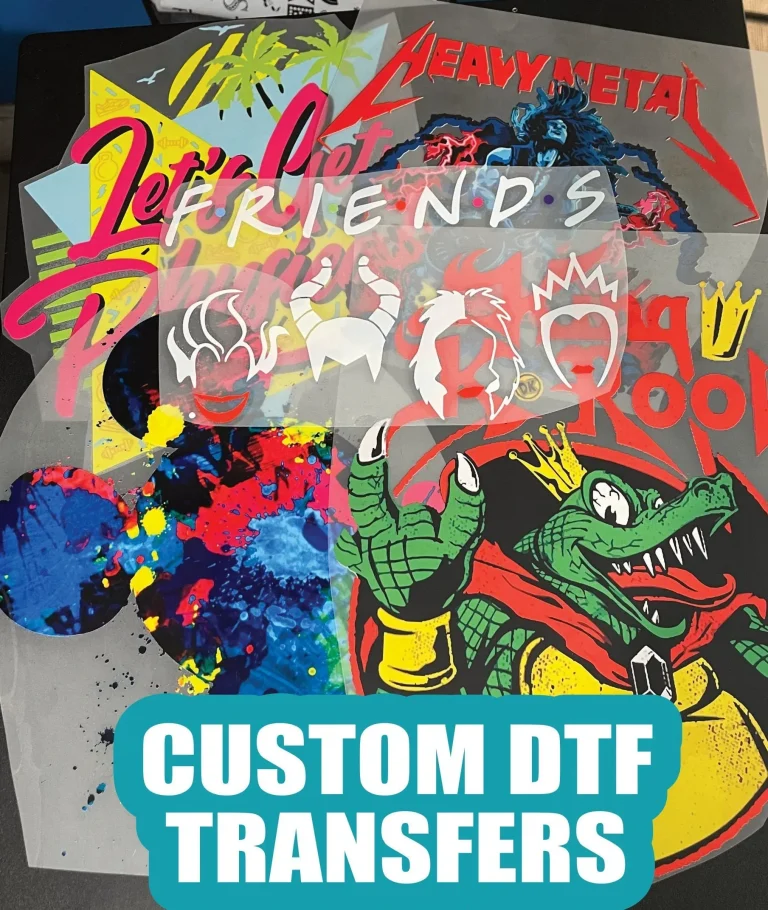

In the realm of personalized merchandise, Direct-to-Film transfers have emerged as a dynamic option for garment decoration. Known for their versatility, these transfers are ideal for businesses seeking efficient custom apparel solutions that maintain high design quality. Comparatively, the choice between DTF options and Direct-to-Garment techniques brings forth interesting discussions regarding their respective pros and cons. The adaptability of DTF printing allows for impressive outputs while minimizing the need for extensive setup—benefits that are particularly appealing for smaller enterprises. As the apparel printing domain evolves, understanding these alternative terminology and methodologies becomes essential for staying ahead in the game.

Understanding DTF Transfers

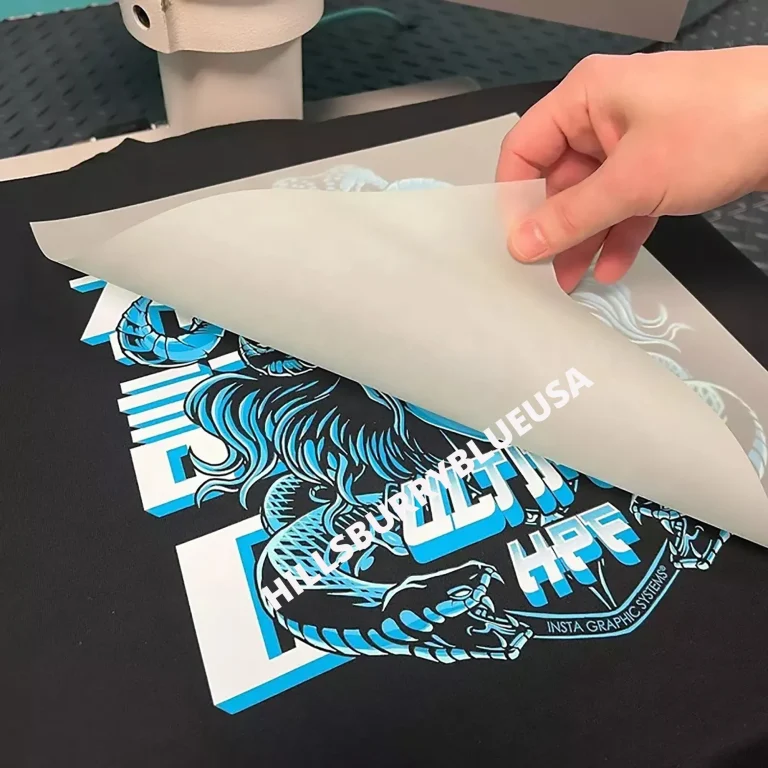

DTF (Direct-to-Film) Transfers represent a revolutionary method in the sphere of custom apparel printing. Utilizing DTF printing technology, designs are printed onto a specially coated film, which is then transferred onto garments through heat. This process not only allows for vibrant prints but also accommodates a variety of fabric types, making it a versatile option for garment decoration. Many businesses are recognizing the growing allure of DTF printing for its cost-effectiveness and ease of use, especially in the burgeoning market of personalized merchandise.

DTF Transfers are particularly invaluable for small businesses and creators who seek to cater to niche markets. With the ability to produce complex designs with minimal effort, the flexibility that DTF offers contrasts sharply with the traditional approaches of garment decorating. Additionally, as technology continues to evolve, the machinery required for DTF printing has become more accessible, leveling the playing field for aspiring entrepreneurs.

The Rise of DTF Printing Technology

Recent advancements in DTF printing technology have spurred a significant rise in its acceptance among printing professionals. Innovations in printer designs, such as the versatile offerings from Brother, are designed to enhance productivity and quality. The integration of DTF with other techniques means businesses can diversify their printing capabilities without extensive capital investment, allowing them to adapt quickly to changing market demands. This not only optimizes operational efficiency but also creates a unique selling proposition in a competitive landscape.

Furthermore, platforms like Snuggle are redefining how garment decoration works. They emphasize on-demand customization, aligning perfectly with consumer trends that favor personalized products. The push for rapid production without the need for extensive equipment showcases how DTF printing technology is enabling businesses to thrive even in saturated markets.

Comparing the Benefits of DTF Transfers and DTG Printing

When delving into the nuances between DTF Transfers and DTG Printing, it’s crucial to consider the distinct benefits each method brings to the table. DTF printing is celebrated for its adaptability, allowing users to easily switch between different fabric types without compromising quality. On the other hand, DTG printing is renowned for its ability to produce high-resolution prints, making it ideal for intricate designs. Businesses need to assess their target market and design requirements to determine which method serves their goals best.

Moreover, while DTF Transfers are often more cost-effective in terms of setup and operational expenses, DTG Printing offers an edge in print durability and color fidelity. This comprehensive understanding of each method’s strengths plays a pivotal role in guiding businesses toward a sustainable printing solution that aligns with their specific needs.

The Pros and Cons of DTF vs. DTG

Understanding the pros and cons of DTF Transfers versus DTG printing is essential for any business looking to establish or expand its custom apparel offerings. DTF Printing’s lower initial investment and quicker setup time can attract small businesses looking to minimize overhead costs. However, durability can sometimes be an issue, especially when prints are exposed to harsh washing conditions. Conversely, DTG Printing provides incredibly vivid, long-lasting prints but comes with higher machinery costs and a more complex cleaning process.

By carefully evaluating these factors, business owners can make informed decisions that align with their operational goals. The right choice hinges on factors including print volume, design complexity, and customer expectations regarding durability and vibrancy.

Innovation in Custom Apparel Printing

The landscape of custom apparel printing is constantly evolving, driven by innovation in both DTF and DTG technologies. At events like Fespa, manufacturers are showcasing new hybrid machines capable of executing both DTF and DTG printing with utmost efficiency, which bridges the gap for businesses wanting to explore multiple printing methods. This innovative approach not only expands production capabilities but also enhances the creative potential for artists and businesses alike.

Moreover, developments such as automated heat transfer presses are changing the way businesses approach garment decoration. By streamlining production processes, companies can significantly increase their output while maintaining quality, providing them with a competitive edge in an ever-demanding market. Embracing these innovations is critical for businesses that aim to keep pace with consumer expectations.

Strategic Decisions in Printing Technology

Making a strategic decision between DTF Transfers and DTG Printing ultimately rests on the unique needs of a business. Factors such as production scale, target demographics, and design complexity are paramount in guiding this decision. Small businesses may find that DTF printing aligns better with their budget and goals, while larger enterprises with higher output demands might lean toward the unmatched quality of DTG methods.

Understanding the current market dynamics and technological advancements will empower businesses to make choices that not only meet their immediate needs but also position them for future growth. As the custom apparel landscape matures, those who stay informed and remain adaptable will undoubtedly succeed.

Frequently Asked Questions

What are DTF Transfers and how do they differ from DTG Printing?

DTF Transfers (Direct-to-Film) utilize a film transfer method to apply designs onto garments, while DTG Printing (Direct-to-Garment) directly prints onto the fabric. DTF is known for its flexibility on various fabric types and lower setup costs, making it favorable for small businesses. In contrast, DTG offers high-resolution prints ideal for intricate designs.

What are the advantages of using DTF printing technology in custom apparel printing?

DTF printing technology offers several benefits, including cost-effectiveness due to lower initial setup fees, flexibility for use on multiple fabric types, and ease of use for novice printers. This makes it an attractive option for small business owners and artists looking for efficient custom apparel solutions.

Are there any downsides to choosing DTF Transfers over DTG Printing?

While DTF Transfers are cost-effective and adaptable, they may have durability concerns; prints might not last as long under certain conditions compared to DTG Printing. Additionally, DTF printing technology may not produce the same high-resolution detail as DTG, making it less suitable for very intricate images.

How does garment decoration differ between DTF Transfers and DTG Printing?

Garment decoration with DTF Transfers involves applying designs to a film and subsequently transferring them to the fabric, which can be versatile for various materials. Conversely, DTG Printing directly applies ink onto the garment, resulting in vibrant, high-quality imagery ideal for complex designs.

Which printing method is more suitable for small batch custom apparel printing?

DTF Transfers are generally more suitable for small batch custom apparel printing due to their lower setup costs and versatility on different fabrics. This makes it easier for small businesses to produce various designs without significant investment, unlike the more expensive DTG Printing equipment requirements.

What should businesses consider when choosing between DTF Transfers and DTG Printing?

When selecting between DTF Transfers and DTG Printing, businesses should evaluate their specific needs, including production volume, fabric types, design complexity, and cost considerations. Additionally, analyzing factors like print durability and maintenance requirements can help in making an informed choice tailored to their operations.

| Key Features | DTF Transfers | DTG Printing |

|---|---|---|

| Definition | Direct-to-Film (DTF) method transfers designs onto garments using a special film. | Direct-to-Garment (DTG) printing involves applying ink directly onto the garment using inkjet technology. |

| Print Quality | Vibrant colors but may vary in durability over time. | High-resolution prints with superior color reproduction. |

| Setup Costs | Lower initial costs and less setup required for different designs. | Higher costs associated with machinery and setup for each new design. |

| Flexibility | Adaptable to various fabric types and garment styles. | Works best with natural fibers and specific fabric types. |

| Eco-Friendliness | Generally less eco-friendly with concerns on print longevity. | Often utilizes water-based inks, making it more environmentally friendly. |

Summary

DTF Transfers provide a modern and versatile approach to custom apparel printing, emerging as a significant alternative to DTG Printing. As businesses navigate their printing options, it’s essential to recognize that while DTF Transfers can offer cost-effective and flexible solutions, DTG Printing remains unmatched in quality, especially for intricate designs. The evolving technologies within both methods suggest that there is a place for both in the industry, and businesses should evaluate their specific needs and the demands of their customers to make the best choice moving forward.