In the dynamic landscape of custom apparel production, DTF transfers stand out as an innovative printing solution that has transformed the industry. Direct-to-Film printing simplifies the process of transferring vibrant images onto various fabric types, catering to the growing demand for personalized designs. With its eco-friendly inks and minimal waste, DTF printing benefits not only businesses but also aligns with the sustainable printing trends that consumers increasingly value. This guide aims to unveil everything you need to know about DTF transfers, from their advantages to the latest technology trends shaping this method. As the custom apparel market evolves, understanding DTF transfers will be crucial for staying ahead in a competitive environment.

Exploring alternative techniques in the world of textile printing, Direct-to-Film technology has emerged as a powerful ally for those involved in garment decoration. This method, often referred to as DTF printing, utilizes specialized films to create stunning designs that can be seamlessly transferred onto fabrics. As sustainable printing gains momentum, the benefits of DTF, including reduced material waste and high-quality outputs, are becoming more apparent. By embracing this cutting-edge technology, businesses can align their practices with current trends while meeting consumer desires for unique and eco-conscious products. Join us as we delve deeper into the intricacies of DTF transfers, uncovering their significance in the thriving custom apparel sector.

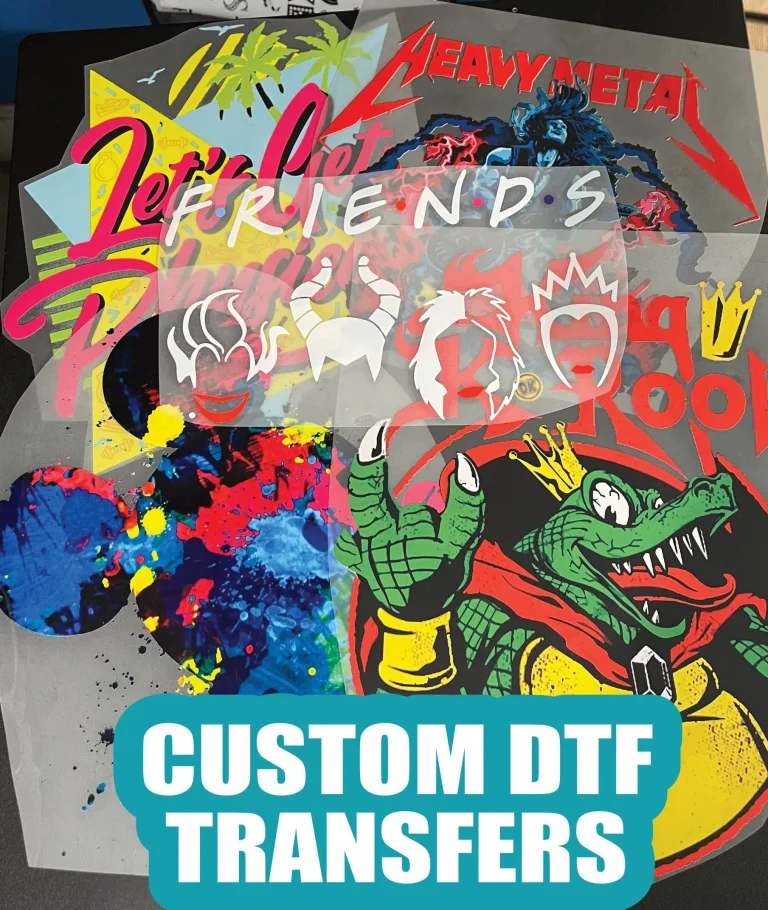

Introduction to DTF Printing: The Next Generation of Custom Apparel

Direct-to-Film (DTF) printing is at the forefront of modern custom apparel production, presenting a lucrative opportunity for businesses in the textile industry. Unlike traditional methods, DTF utilizes a specialized film that allows for sharp, vibrant designs to be transferred seamlessly to a variety of fabrics. This innovative technology not only ensures stunning visual quality but also paves the way for enhanced customization options, making it an attractive choice for consumers who value individuality in their fashion choices.

The rise of DTF printing reflects a broader shift towards personalized merchandise that appeals to modern consumers. As customers increasingly seek unique, one-of-a-kind apparel, DTF provides the flexibility to cater to these demands efficiently. With its ability to print complex and colorful designs quickly, DTF has positioned itself as a frontrunner in the realm of custom apparel printing.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct-to-Film transfers, are a modern printing method that involves printing designs onto a special film which is then heat-pressed onto various fabrics. The process includes printing the design, applying adhesive powder to bond the ink, pre-heating the film, and finally pressing the film onto the fabric to create durable and vibrant custom apparel.

What are the benefits of using DTF printing for custom apparel?

DTF printing offers several benefits for custom apparel, including vibrant color reproduction, compatibility with various fabric types, less waste compared to traditional methods like screen printing, quick setup times, and the ability to easily produce high-quality designs for short runs and personalized items.

How does DTF printing compare to other printing technologies?

Compared to traditional printing methods such as screen printing and DTG printing, DTF printing is more versatile and produces less waste. It allows for vibrant, high-quality prints on a wide range of fabrics, making it an efficient choice for businesses looking to offer diverse custom apparel options.

Are DTF Transfers environmentally friendly?

Yes, DTF Transfers can be environmentally friendly, especially with the use of eco-friendly inks and adhesive powders. Recent innovations in DTF printing technology focus on reducing waste and ensuring the inks used meet modern environmental standards, appealing to sustainability-conscious consumers.

What trends are influencing the growth of DTF Transfers in the market?

Current trends driving the growth of DTF Transfers include an increasing demand for personalized merchandise, advancements in printing technology, and the rise of eco-friendly practices. These factors combine to make DTF printing a popular choice for custom apparel among decorators and businesses.

What should I consider when starting a DTF printing business?

When starting a DTF printing business, it is crucial to invest in high-quality equipment such as printers, films, and heat presses, understand the workflow involved, and ensure regular maintenance of your equipment. Mastering these aspects will help ensure high-quality output and efficient operations.

| Key Point | Description |

|---|---|

| What are DTF Transfers? | A printing method where designs are printed onto a film and transferred to fabrics using heat, consisting of four main steps: printing, applying adhesive, pre-heating, and pressing onto the fabric. |

| Advantages of DTF Transfers | Includes vibrant colors, less waste, versatility with various fabrics, and quick setup for custom designs. |

| Current Trends in DTF Printing | Customization demand is rising, alongside technological advancements that improve printer and material quality. |

| Material Innovations | Focus on eco-friendly inks and adhesives, as well as durability improvements of prints through advanced technologies. |

| Market Outlook | Predicted substantial growth due to increased demand for personalized merchandise and continuous technological advancements. |

| Practical Considerations | Investment in quality equipment, understanding the printing workflow, and regular maintenance are crucial for success in the DTF market. |

Summary

DTF Transfers represent a groundbreaking approach to customizable apparel, merging creativity with innovative technology. As the industry shifts towards personalization and sustainability, understanding DTF transferring methods is key for businesses looking to thrive. With vibrant designs and a versatile application process, DTF Transfers not only cater to aesthetic demands but also promote efficient production practices. By embracing these advancements, businesses can effectively meet market needs and capture the growing consumer interest in unique, high-quality clothing. This makes DTF Transfers an essential topic for anyone in the textile and printing industry today.