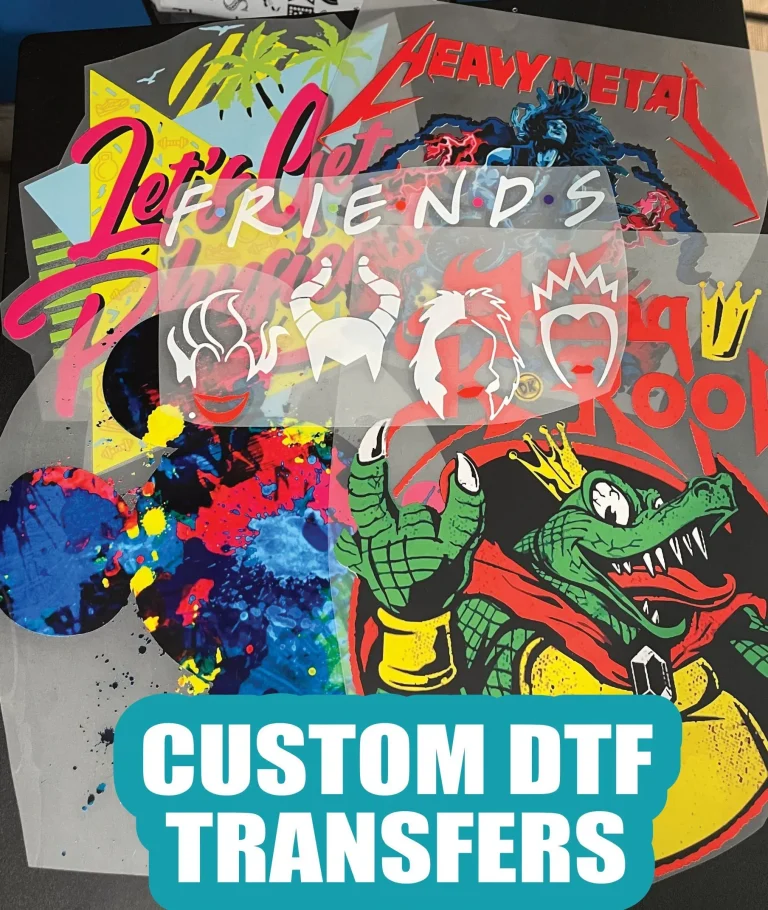

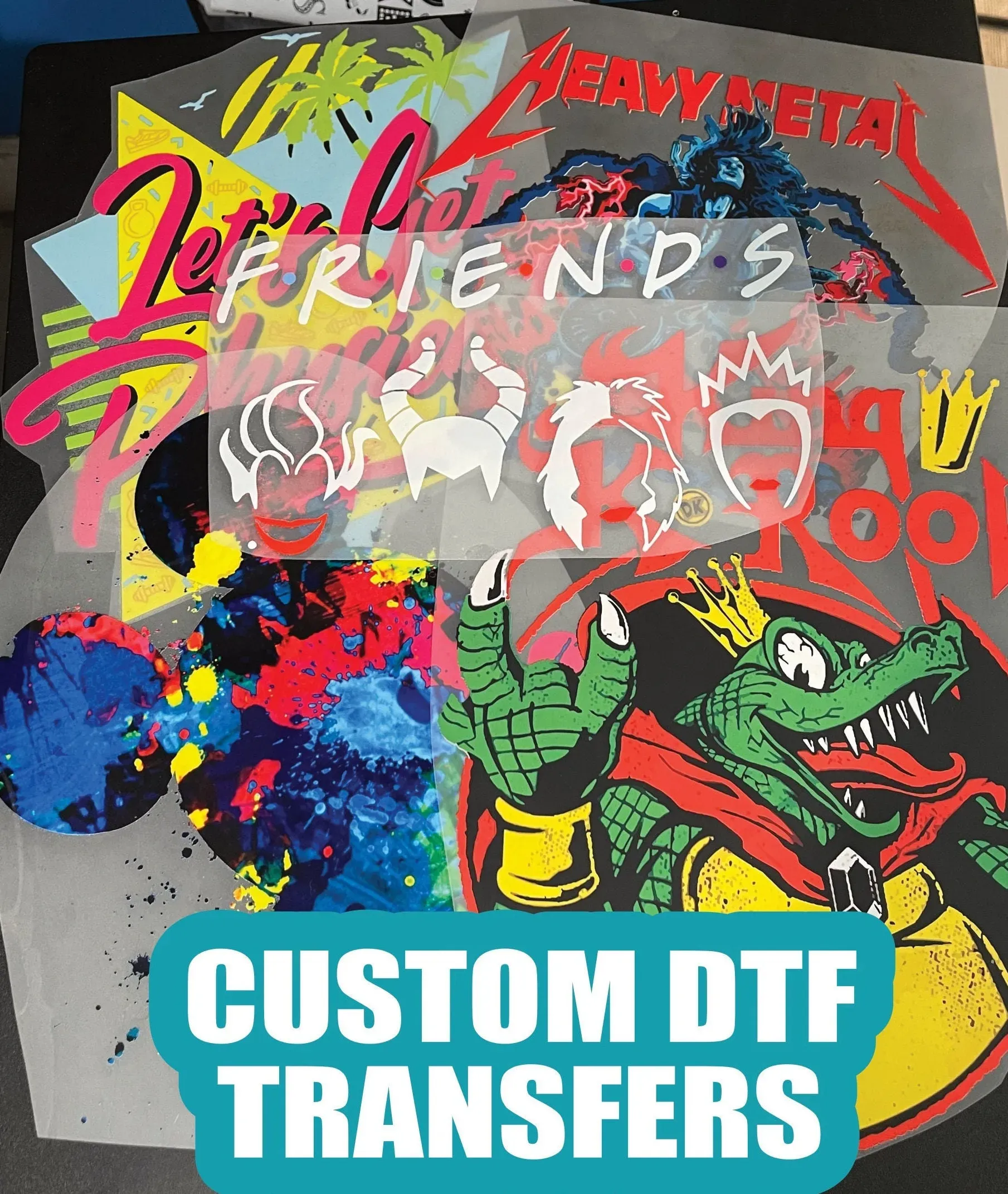

In the evolving landscape of custom apparel printing, DTF transfers, or Direct-to-Film transfers, are rapidly changing the game. Known for their ability to produce vibrant designs, this printing technology offers an eco-friendly alternative that resonates with both businesses and environmentally conscious consumers. Unlike traditional printing methods, DTF technology allows for intricate details and durable prints, empowering creators to bring their artistic visions to life. This comprehensive guide will delve into the mechanics of DTF transfers, their sustainable implications, and how this innovative printing method is reshaping the future of custom apparel. From small businesses to enthusiastic hobbyists, the possibilities with DTF are endless.

Exploring alternatives to traditional printing, Direct-to-Film (DTF) transfers are at the forefront of custom garment creation. These innovative print solutions harness advanced technology to produce stunning visuals while emphasizing sustainability, making them a favored choice among creators. Known for vibrant graphic applications, DTF offers an accessible way for artists and entrepreneurs to craft unique designs on various textiles. With its ability to reduce waste and support eco-friendly printing practices, this method stands out in a crowded marketplace. As DTF printing continues to gain traction, it opens doors to a world rich in vibrant color and artistic expression.

The Benefits of DTF Transfers for Custom Apparel

DTF transfers have quickly become a favorite among businesses and individuals in the custom apparel industry due to their ability to produce exceptionally vibrant designs. The DTF printing process allows for a wide color spectrum and intricate detailing, which attracts graphic designers eager to create standout pieces. Unlike some traditional printing methods that can struggle with gradient transitions or minute design elements, DTF excels, ensuring that every nuance of the artwork is vividly reproduced on fabric.

Moreover, the durability of DTF prints is another key benefit that cannot be overlooked. These prints are not only bright and detailed; they are built to last, resisting fading and cracking over time. This makes DTF transfers an ideal choice for businesses that offer apparel intended for everyday wear, such as t-shirts, hoodies, and bags. Clients appreciate knowing that they are receiving high-quality products that can withstand the rigors of frequent washing and wearing.

Sustainable Printing Practices: How DTF Transfers Make a Difference

Sustainability is a growing concern in the fashion and printing industries, and DTF technology shines as a leading solution for eco-conscious businesses. The relatively low waste produced in DTF printing compared to traditional methods, like screen printing, makes it an attractive option for brands committed to environmental stewardship. With DTF, there’s no need for extensive setup and manual adjustments, leading to reduced material waste and a smaller ecological footprint.

Additionally, DTF’s capabilities allow for on-demand printing, meaning designs can be printed as needed, further minimizing waste from unsold inventory. This adaptability supports sustainable business models that favor limited runs and personalized orders, which are increasingly appealing to today’s consumers who prioritize sustainability in their purchasing decisions.

Exploring Advanced DTF Technology for Vibrant Designs

As the demand for unique and vibrant designs in custom apparel rises, DTF technology is evolving to meet these needs with astonishing advancements. Modern DTF printers are now capable of producing not just exceptional color fidelity but also a variety of textures and finishes that can enhance the appeal of the clothing. This versatility allows designers to experiment with their ideas and push the boundaries of conventional garment decoration.

Furthermore, the integration of cutting-edge ink formulations in DTF printing is helping to achieve even more vibrant designs. These new inks not only provide vivid colors but also adhere better to fabrics, ensuring that the designs maintain their brilliance after multiple washes. Innovations in the DTF process, like pre-treatment and post-curing options, are enabling creators to achieve a professional level of quality in their home or small business setup.

Market Trends: The Rise of DTF Printing Equipment

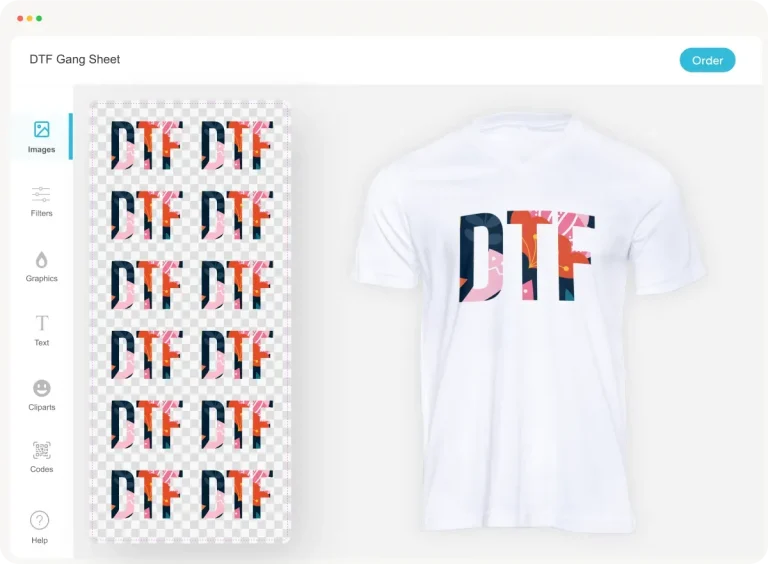

In recent years, the market for DTF printers and equipment has expanded significantly, reflecting the growing enthusiasm for this innovative printing method. Companies are launching compact and user-friendly DTF printers designed specifically for small businesses and hobbyists. The availability of easier-to-use technology encourages more people to delve into custom apparel printing, democratizing access to high-quality printing solutions.

Moreover, as brands increasingly recognize the value of offering inspired and personalized apparel, the market for DTF transfers is likely to continue its upward trajectory. The quest for unique designs has never been more attainable, as DTF technology evolves with enhanced features, improving the overall reliability and accessibility of printing. This trend not only benefits individual creators but also businesses looking to diversify their offerings and cater to customer demands for customization.

Customizable Options: Personalization through DTF Printing

The advent of DTF transfers has opened new avenues for customization in apparel design, allowing consumers to express unique identities and preferences through personalized prints. DTF printing enables hobbyists and small business owners to create custom apparel that resonates with their audience, providing a fresh alternative to mass-produced items. From hobbyists crafting personalized gifts to brands promoting unique collections, DTF offers a creative outlet that adapts to individual visions.

Additionally, as customization becomes increasingly popular, the flexibility of DTF printing supports a broad range of applications, including promotional items, special event clothing, and fashion-forward styles. This adaptability not only empowers users by allowing complete creative control but also strengthens brand loyalty as consumers enjoy expressing their individuality.

A Comparative Look at DTF vs. Traditional Printing Methods

When considering the most effective methods for custom apparel printing, a comparative analysis between DTF and traditional technologies such as screen printing and sublimation reveals notable advantages of DTF. One significant benefit is the ability of DTF to print on diverse fabric types, including cotton and blends, where traditional methods may have limitations. This versatility is crucial for businesses looking to expand their product offerings and cater to varying consumer preferences.

Furthermore, DTF technology is often more economical for small businesses seeking to fulfill custom orders. Unlike screen printing, which typically requires large minimums due to setup costs, DTF allows for smaller batch sizes without sacrificing quality. This flexibility encourages entrepreneurs to explore creative possibilities and respond to short-run or one-off requests that can capture specific market interests.

Frequently Asked Questions

What are DTF transfers and what makes them suitable for vibrant designs?

DTF transfers, or Direct-to-Film transfers, involve printing designs on a special film before adhering them to textiles. This method enables the production of vibrant designs with rich colors and detailed gradients, making it a preferred choice for custom apparel.

How do DTF technology and sustainable printing practices work together?

DTF technology aligns with sustainable printing practices by minimizing waste and utilizing eco-friendly materials. This process enables multiple prints without extensive setup, appealing to both environmentally conscious brands and consumers.

Why should businesses consider DTF transfers for custom apparel production?

Businesses should consider DTF transfers for their custom apparel production due to their vibrant design capabilities and cost-effectiveness. This printing method allows for high-quality results with low setup costs, making it ideal for small businesses and hobbyists alike.

Can DTF transfers be used on a variety of fabrics?

Yes, DTF transfers can be used on a wide range of fabrics, including cotton, polyester, and blends. This versatility is a significant advantage over other printing methods, allowing designers to expand their creative possibilities on different substrates.

What are the benefits of using DTF printing compared to sublimation?

DTF printing offers several benefits over sublimation, including the ability to print on diverse fabric types and excellent color vibrancy. Additionally, DTF does not require pre-treatment of fabrics, making it easier to achieve impressive results on various materials.

How accessible is DTF transfer technology for individual users and small businesses?

DTF transfer technology is highly accessible, with compact printers designed for home users and small businesses. These user-friendly machines empower creatives to produce stunning custom apparel without extensive technical knowledge or high initial investments.

| Key Points | Details |

|---|---|

| Introduction | Overview of DTF transfers impact on custom apparel printing. |

| Understanding DTF Transfers | Involves transferring designs onto a special film that adheres to textiles with heat and pressure, providing vibrant colors and durability. |

| Key Benefits | 1. Vibrant Designs: Exceptional color and detail handling. 2. Sustainability: Reduces waste and environmental impact. 3. Cost-Effectiveness: Affordable solutions for small businesses. |

| Sustainability in Apparel Production | Aligns with sustainability goals by minimizing waste and offering eco-friendly production practices. |

| Market Expansion and Accessibility | Increase in DTF technology investments, making it accessible for small businesses and hobbyists. |

| Advanced Consumer Options | Growth of DIY culture with high-quality DTF printers suitable for home users and enthusiasts. |

| Comparative Analysis | DTF shows advantages over methods like sublimation in fabric variety and printing capabilities. |

| Conclusion | DTF transfers are revolutionizing custom apparel design with sustainability, vibrancy, and accessibility. |

Summary

DTF transfers are transforming the landscape of custom apparel printing with their vibrant designs, sustainable practices, and affordability. This innovative technology allows creators and businesses to produce high-quality, detailed prints while minimizing environmental impact. As the market for DTF printing continues to grow, it not only offers an array of options for designers but also meets the increasing consumer demand for eco-friendly practices. With advancements in equipment accessibility, both hobbyists and small businesses can easily adopt this versatile printing method, positioning DTF transfers as a leading choice in the world of custom apparel.