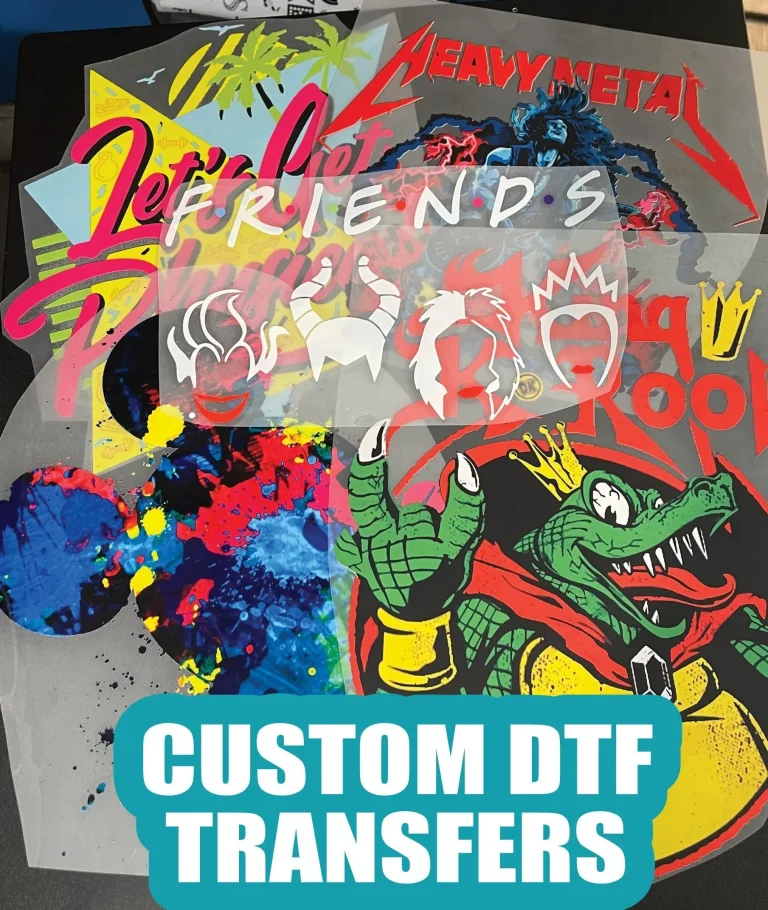

DTF transfers, or Direct to Film transfers, are revolutionizing the world of custom apparel printing, making it easier than ever for both beginners and experts to create stunning designs. This innovative printing method utilizes high-quality water-based inks to produce vibrant graphics on a specialized film, which can then be heat pressed onto various fabrics, such as cotton and polyester. The DTF printing process not only allows for intricate designs but also ensures durability and longevity after numerous washes, setting it apart from other printing techniques. With clear advantages—ranging from versatility to user-friendliness—DTF transfer benefits are sparking interest among small business owners and DIY enthusiasts alike. As we delve deeper into this topic, you’ll discover how to effectively use DTF transfers and the steps needed to harness this powerful printing technology.

Exploring the realm of Direct to Film printing, we uncover a captivating method for customizing apparel that is gaining momentum in the creative community. Also known as film transfer printing, this technique has garnered attention for its ability to deliver high-resolution images with ease. Whether you’re a hobbyist or someone looking to enhance your business’s product line, understanding the nuances of this printing method can open doors to endless creative possibilities. The popularity of this approach lies not only in its effectiveness but also in the myriad options it offers for personal expression through personalized clothing. As we unpack the different facets of DTF transfers, you’ll learn about the foundational elements necessary for successful application in garment printing.

Understanding the DTF Printing Process

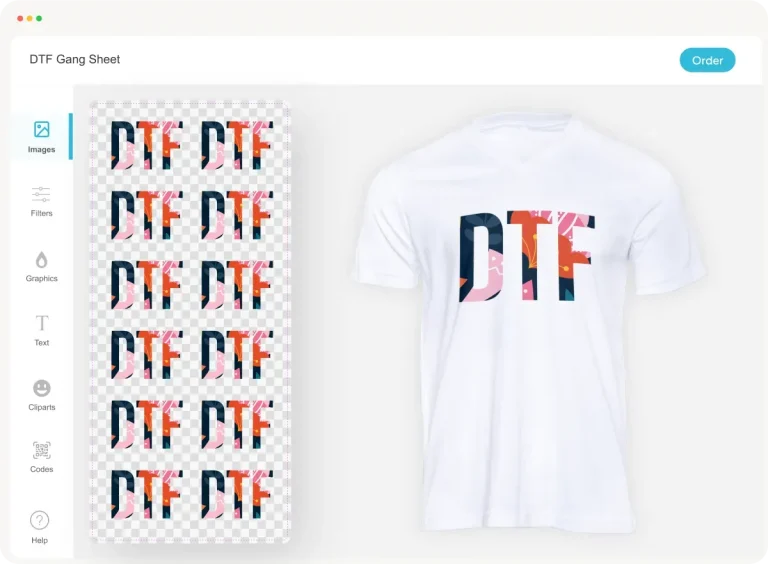

The DTF printing process, which stands for Direct to Film printing, is revolutionizing the way we can transfer designs onto fabric. This innovative method begins with printing your artwork onto a unique film. Using special water-based inks, the designs are printed in high resolution, capturing every detail and color vibrancy. After printing, an adhesive powder is applied to the still-wet ink, and the film is then heat-cured. This crucial step ensures that the adhesive bonds effectively with the inks, allowing for a flawless transfer later on.

Once your design is prepared on the film, it’s time to transfer it onto the garment of your choice. Utilizing a heat press, which is an essential piece of equipment in this process, you can firmly affix your printed design onto various fabric types, including cotton, polyester, and blends. The heat press activates the adhesive, securing the print to the material permanently. This method is both efficient and provides impressive results, making DTF an attractive option for businesses looking to create custom apparel.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct to Film transfers, are a method of applying vibrant designs onto fabrics such as cotton and polyester. The DTF printing process involves printing designs onto a special film using water-based inks, followed by transferring the design to the garment with a heat press. This aligns with the needs of custom apparel printing, allowing for high-resolution, durable prints.

What are the benefits of using DTF Transfers for custom apparel?

DTF Transfers offer numerous benefits for custom apparel, including versatility as they can be applied to diverse types of fabrics, durability with prints that withstand multiple washes, and ease of use which allows beginners to quickly learn the DTF printing process and create unique designs.

How can I start using DTF Transfers for my projects?

To get started with DTF Transfers, you’ll need specific equipment such as a DTF printer, heat press, and transfer films. Gather supplies including DTF inks and adhesive powder. Follow the DTF process: print the design on the film, add adhesive, heat-cure the print, and use a heat press to transfer it onto the garment.

What makes DTF Transfers a popular choice for small businesses?

DTF Transfers have gained popularity among small businesses due to their cost-effectiveness, ease of setup compared to traditional printing methods, and the ability to create high-quality, custom apparel quickly. This flexibility allows businesses to meet a variety of customer demands without significant overhead.

Can DTF Transfers be used on all types of fabrics?

Yes, DTF Transfers are incredibly versatile and can be applied to a wide range of fabrics including cotton, polyester, and blends. This adaptability makes them a popular choice in the custom apparel printing industry, allowing for creativity across various garment types.

What innovations are emerging in the DTF printing process?

Innovations in the DTF printing process are leading to improved print quality and faster production times. The industry is also seeing a rise in eco-friendly inks and materials, aligning with growing environmental concerns, which is shaping the future landscape of DTF Transfers and custom apparel printing.

| Key Point | Details |

|---|---|

| What are DTF Transfers? | A printing method where vibrant designs are applied onto fabrics using water-based inks and a heat press. |

| Benefits of DTF Transfers | 1. Versatility: Applicable on various fabrics. 2. Durability: Long-lasting quality after multiple washes. 3. Ease of Use: Simple process suitable for beginners. |

| Getting Started with DTF Transfers | 1. Equipment needed: DTF Printer, Heat Press, Transfer Films. 2. Supplies: DTF Inks, Adhesive Powder. 3. DTF Process: Print design, add adhesive, cure print, heat transfer. |

| Recent Trends | Increased adoption among creators and small businesses due to ease and cost-effectiveness, fostering broader access through e-commerce. |

| Future Directions | Advancements in printing technology leading to better quality and quicker production times. A rising demand for eco-friendly inks and materials. |

Summary

DTF Transfers represent a revolutionary approach in the realm of custom apparel printing. Offering an accessible entry point for both beginners and experienced creators, DTF transfers enable vibrant designs to be effortlessly transferred to a variety of fabrics. The versatility, durability, and user-friendly nature of DTF printing have captured the interest of hobbyists and small businesses alike, marking a significant trend in the industry. As technology continues to evolve, the future of DTF transfers looks promising with innovations enhancing the quality and sustainability of prints. Embrace the creativity that DTF transfers provide and dive into the exciting world of custom printing!