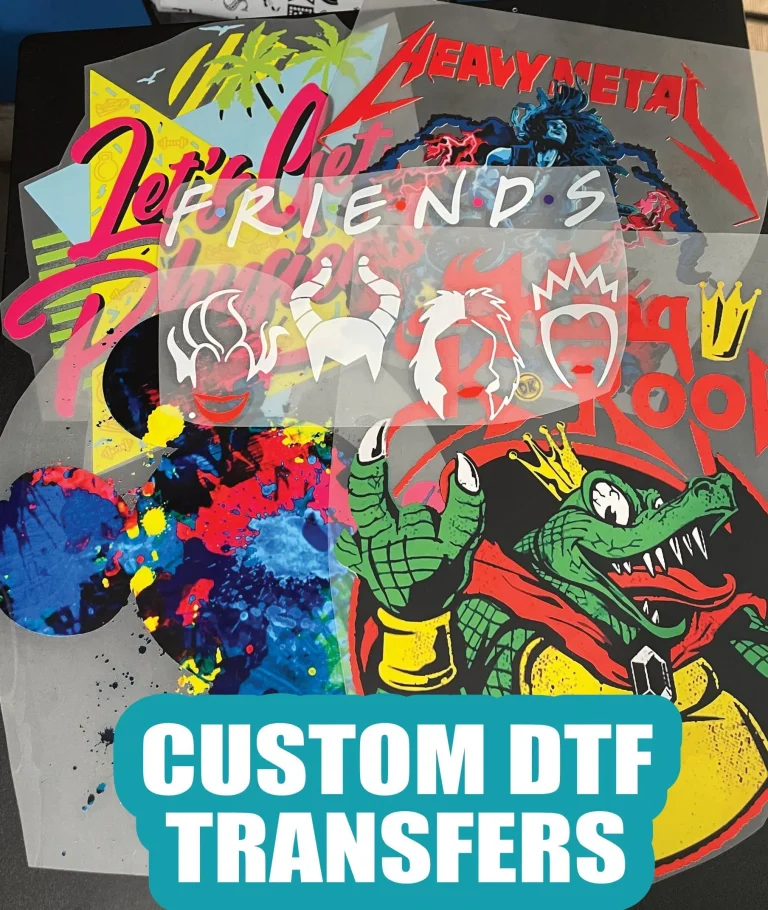

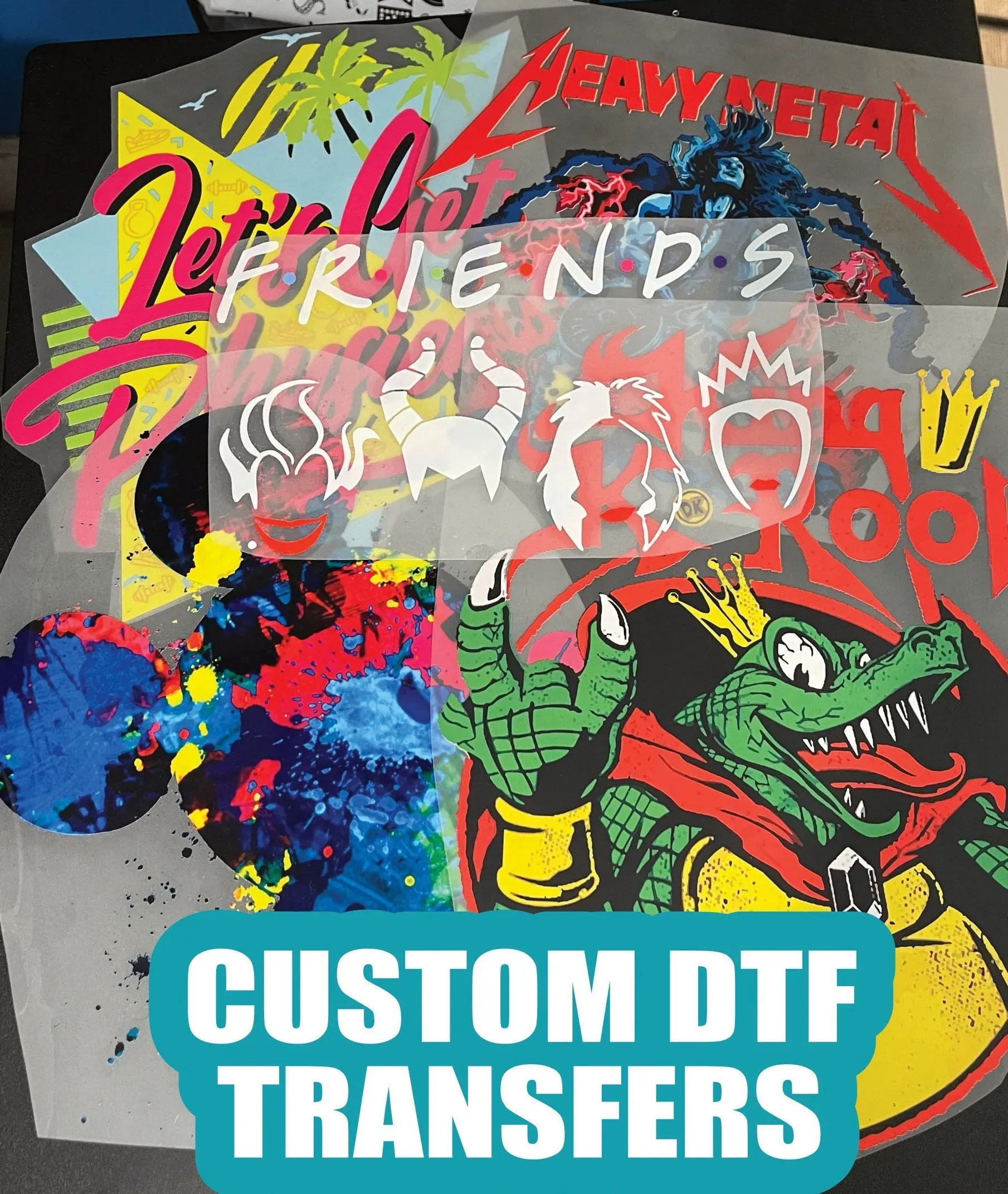

DTF transfers, or Direct to Film transfers, have revolutionized the custom apparel industry, enabling designers to craft vibrant, high-quality clothing with ease. This innovative transfer printing technique is not just a trend but a game-changer for both professional and amateur creators alike. Whether you’re designing unique garments for personal use or starting a new small business, mastering DTF transfers can significantly elevate your creative output. With helpful creative design tips and custom printing techniques, you can learn how to make your visions come to life on fabric. Join us as we explore the exciting DTF printing process and discover ways to enhance your custom apparel projects.

The term “Direct to Film” (DTF) printing has emerged in the realm of personalized garment creation, offering a modern approach to transfer printing technologies. This method allows for intricate designs to be effortlessly transferred onto various fabrics, making it an ideal choice for custom fashion enthusiasts. As the popularity of this technique grows, many are seeking effective strategies to leverage unique creative design tips and specialized custom printing methods. Understanding how to navigate the DTF printing process can empower you to produce eye-catching apparel that reflects individual artistry. Engaging in the world of DTF transfers opens up a myriad of opportunities for those looking to make a mark in the custom apparel market.

Understanding DTF Transfers: A Game Changer in Custom Apparel

DTF transfers, or Direct to Film transfers, have revolutionized the way custom apparel is designed and produced. Unlike traditional methods that may restrict creativity or require extensive training, DTF printing processes bring together high-quality print capabilities and user-friendliness, making it a favorite among both hobbyists and professional printers. This method offers vibrant colors and intricate details that are particularly appealing for shirts, hoodies, and other garments, breaking the boundaries of traditional transfer printing.

The appeal of DTF transfers lies not only in their quality but also in the versatility they provide. Creators can apply these transfers to a variety of fabrics, including cotton and poly blends, ensuring that designs maintain their vibrancy and durability over time. As more creators adopt this technology, understanding how to effectively use DTF transfers can set you apart in a crowded market, allowing for unique and standout pieces that resonate with customers.

Essential Materials for DTF Transfers

Choosing the right materials is fundamental to achieving stunning results with DTF transfers. It’s important to invest in high-quality DTF films and inks, as these will directly affect the final appearance and longevity of your designs. Superior materials not only produce clearer images but also enhance the durability of the clothing; therefore, fabric selection should never be overlooked. Opt for fabrics that are known to work well with this printing technique, such as 100% cotton or poly-cotton blends, to ensure a lasting finish.

In addition to selecting the right fabrics and inks, using premium quality printer equipment can significantly improve your experience with DTF transfers. High-resolution printers, paired with the correct settings, will yield better ink distribution, capturing intricate details and vibrant colors ideal for creating standout custom apparel. Taking the time to understand the specifications and capabilities of your equipment, while investing in quality materials, will ultimately enhance your design outcomes.

Mastering the DTF Printing Process

The DTF printing process involves several crucial steps that greatly influence the outcome of your custom apparel. Before printing, preparing your designs is essential; using vector graphics is recommended to ensure sharp, clear images. Software like Adobe Illustrator can help you create designs at an optimal resolution of 300 DPI or higher, which is critical for capturing every detail in your prints. This attention to detail during the design phase sets the foundation for a successful transfer.

Once you’ve created your designs, understanding how to optimize printer settings is key in the DTF process. Each printer may require specific configurations regarding ink density, speed, and other parameters. Taking the time to experiment with these settings can lead to improved vibrancy and clarity in your finished products. Proper preparation in these early stages will ensure your DTF transfers have the best possible start before they even hit the press.

Effective Heat Press Techniques for DTF Transfers

Heat pressing is a critical element in the application of DTF transfers and mastering this technique can lead to impressive results. A common practice includes pre-pressing your fabric, which eliminates unwanted moisture that can disrupt the transfer process. Additionally, setting your heat press to approximately 320°F for 12-15 seconds is generally effective. Ensuring even heat distribution across the design is crucial, as uneven heat can result in poor adhesion or misalignment.

Moreover, it’s important to apply consistent pressure during the pressing process. Different garments might require adjustments in both time and pressure to achieve the desired adhesion and quality. Experimenting with these variables will lead to better outcomes and help you become proficient in using this essential tool for applying DTF transfers on custom apparel.

Aftercare for Custom Apparel Printed with DTF Transfers

After creating beautiful custom apparel with DTF transfers, proper aftercare is key to preserving the quality of your designs. Educate your customers on the importance of cold washing their garments and hang drying them to extend the life of the prints. This simple routine can help prevent fading and ensure that the vibrant colors of the DTF transfers continue to shine through wash after wash.

Moreover, providing clear aftercare instructions can enhance customer satisfaction and loyalty. Including care labels or pamphlets with your products not only serves as a reminder for your customers but also demonstrates your professionalism and commitment to quality. By emphasizing proper care, you help maintain the integrity of the DTF transfers, ensuring your creations remain as stunning as they were on the day they were purchased.

Exploring Current Trends in the DTF Transfer Market

The DTF transfer market is evolving rapidly, driven by increasing demand for personalized and unique custom apparel. As creators explore their avenues in this growing field, more affordable and user-friendly DTF printing equipment continues to emerge. This accessibility allows individuals from various skill levels to enter the market, fostering creativity and innovation in design.

Additionally, as online marketplaces flourish, enthusiasts of custom printing have greater access to resources and communities that support their artistic journeys. Engaging with these platforms not only promotes learning but also allows creators to stay informed about the latest trends and technologies in DTF printing, maximizing their potential to deliver exceptional, customized designs.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel?

DTF transfers, or Direct to Film transfers, are a printing technique used to apply vibrant designs to fabrics. This process involves printing a design onto a special film and using heat to transfer that image onto fabric, creating high-quality custom apparel with bright colors and sharp details.

How can I optimize my designs for DTF printing?

To optimize your designs for DTF printing, use vector graphics for sharper images and create your designs at a minimum of 300 DPI. Programs like Adobe Illustrator are ideal for crafting high-resolution designs that will look great when printed on custom apparel.

What materials should I choose for the best DTF transfers?

For the best results with DTF transfers, choose high-quality DTF films and inks, and work with fabrics like cotton or poly-cotton blends. These materials provide excellent color vibrancy and durability, ensuring your custom apparel withstands wear.

What are some key tips for the DTF printing process?

Key tips for the DTF printing process include optimizing your printer settings for ink density and speed, mastering the heat pressing technique at about 320°F for 12-15 seconds, and pre-pressing fabrics to eliminate moisture for better transfer adhesion.

How do I care for custom apparel printed with DTF transfers?

To care for custom apparel printed with DTF transfers, recommend cold washes and hang drying to customers. This helps preserve print quality and prevents fading, ensuring that the apparel remains vibrant and lasts longer.

What trends are emerging in the DTF transfer market for custom printing?

Emerging trends in the DTF transfer market include the rising demand for personalized printing services and advancements in user-friendly equipment. As technology evolves, more creators are entering the custom apparel space, driving innovation and accessibility in transfer printing options.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | DTF transfers are a print technology using transfer films to apply vibrant designs to fabric, ideal for high-quality custom apparel. |

| The Rise of DTF Transfers | DTF transfers are becoming popular among individuals and businesses due to their simplicity and output quality. |

| Essential Tips for DTF Transfers | 1. Choose quality materials like DTF films and cotton blends. 2. Prepare designs using vector graphics at 300 DPI. 3. Optimize printer settings for better results. 4. Master heat pressing techniques. 5. Ensure proper aftercare, advising cold washes and hang drying. |

| Market Trends | The DTF transfer market is rapidly growing, driven by high demand for personalized printing services and technological advancements. |

Summary

DTF transfers present an innovative solution for creating stunning custom apparel that captivates consumers. By utilizing high-quality materials and intricate design preparation, you can optimize the DTF printing process to achieve professional outcomes. Mastering key techniques such as heat pressing and the right aftercare practices ensures that your creations have lasting durability and vibrancy. The growing demand for personalized apparel showcases the potential of DTF transfers as a creative avenue, allowing artists and entrepreneurs alike to cater to unique styles and preferences. Embrace this evolving landscape and leverage DTF printing to explore endless possibilities in the realm of fashion.