DTF transfers, or Direct to Film transfers, are revolutionizing the way print shops operate, bringing unprecedented efficiency and creativity to fabric printing. This innovative process allows designs to be seamlessly printed onto a special film, which can then be transferred to a wide range of materials with striking vibrancy and detail. As print shop owners increasingly seek methods to enhance their offerings, understanding the DTF printing process has become essential for achieving print shop success. When executed with a focus on quality control, DTF transfers not only generate stunning visuals but also cater to diverse customer needs. In this article, we will explore effective strategies to maximize the benefits of DTF transfers and elevate your print business in today’s competitive landscape.

Exploring the world of DTF printing translates into understanding a groundbreaking approach to fabric decoration. Known as Direct to Film, this technique harnesses specialized films for efficient, high-quality printing that surpasses traditional methods like screen or heat transfer printing. By utilizing cutting-edge technology, businesses in the print industry can unlock new possibilities for customization, catering to various textiles, including cotton and blends. Each DTF transfer encapsulates not just beautiful designs but also the potential for high customer satisfaction and brand loyalty. As we delve deeper into this topic, we will discuss the pivotal elements that contribute to successful DTF printing, from equipment selection to effective marketing strategies.

Understanding the Advantages of DTF Printing

Direct to Film (DTF) printing has emerged as a groundbreaking technique within the textile printing industry. One of its primary advantages is the ability to create high-quality prints with vibrant colors and intricate details. This method utilizes a specialized film that allows for the transfer of designs onto various fabric types, including cotton, polyester, and even blends. The versatility in fabric compatibility gives print shops the freedom to expand their offerings, appealing to a broader clientele and diverging from traditional limitations seen in methods like screen printing.

Moreover, DTF printing is particularly appealing for those looking to produce small to medium-sized runs efficiently. Unlike traditional methods that often require extensive setup time, DTF allows for quicker print jobs, making it ideal for custom orders. This speed, paired with the potential for high-quality results, positions print shops that utilize DTF transfers as leaders in fulfilling customer demands swiftly without compromising on quality.

Choosing the Right Equipment for DTF Success

Investing in the right equipment is crucial for achieving success with DTF printing. Top-tier printers from brands like Epson and Brother have established themselves as industry standards thanks to their reliability and print quality. Alongside these printers, high-quality DTF films and powders are essential. Selecting superior DTF powders ensures better adhesion during application, while premium films enhance the durability and vibrancy of your prints. This investment in quality translates to better products and, ultimately, happier customers who are more likely to return.

Additionally, it is vital to maintain and regularly calibrate your machines to ensure optimal performance. High-performing equipment paired with proper maintenance routines can make a significant difference in print quality and machine longevity. As DTF technology continues to advance, staying updated on the latest equipment trends and innovations will help your print shop maintain a competitive edge.

Streamlining the DTF Printing Process

To optimize the DTF printing process, it’s critical to adopt a systematic approach. Start by understanding pre-treatment requirements for various fabric types, as some materials may require a pre-treatment application for the adhesive powder to bond effectively. This extra step can streamline your workflow, reduce print failures, and ensure high-quality results from the outset. Familiarizing yourself with your materials will ultimately save time and resources in the long run.

Moreover, curing the adhesive powder correctly before applying heat is of utmost importance. Failing to properly cure can result in print quality issues that hinder customer satisfaction. Ensuring your heat press is correctly calibrated will help distribute heat evenly, crucial for successful transfers. By refining these processes, print shops can achieve greater efficiency and consistently produce top-tier products that meet customers’ expectations.

Quality Control Measures for DTF Printing

Implementing strong quality control measures is imperative for maintaining the standards of your DTF printing operations. Conducting checks at each stage of production minimizes errors and reduces the likelihood of returning defective prints. After printing, always inspect each transfer to ensure it meets your quality benchmarks. This includes evaluating the vibrancy of the prints and adhesion quality of the DTF film.

Incorporating thorough testing before launching into larger production runs can help identify and rectify potential issues early. Sticking to a robust quality assurance protocol will not only enhance customer satisfaction but also bolster your shop’s reputation for reliability in DTF printing. Consistency in quality will drive repeat business and build trust with your customer base.

Effective Marketing Strategies for DTF Products

Engaging customers through targeted marketing is essential for print shop success. Identify subsets of your market that could particularly benefit from custom DTF prints. Opportunities abound with local sports teams, schools, and small businesses looking for distinctive merchandise. By crafting personalized marketing campaigns that appeal to these niches, you can create a loyal customer base eager to collaborate on custom designs.

Utilizing digital marketing tools, such as social media platforms, can further enhance your outreach efforts. Showcasing your DTF print capabilities through visual content and success stories can attract new clients while keeping existing ones engaged. Building a brand presence online fosters community and increases visibility in a crowded market, driving sales and helping your business thrive.

Showcasing Creativity to Attract Clients

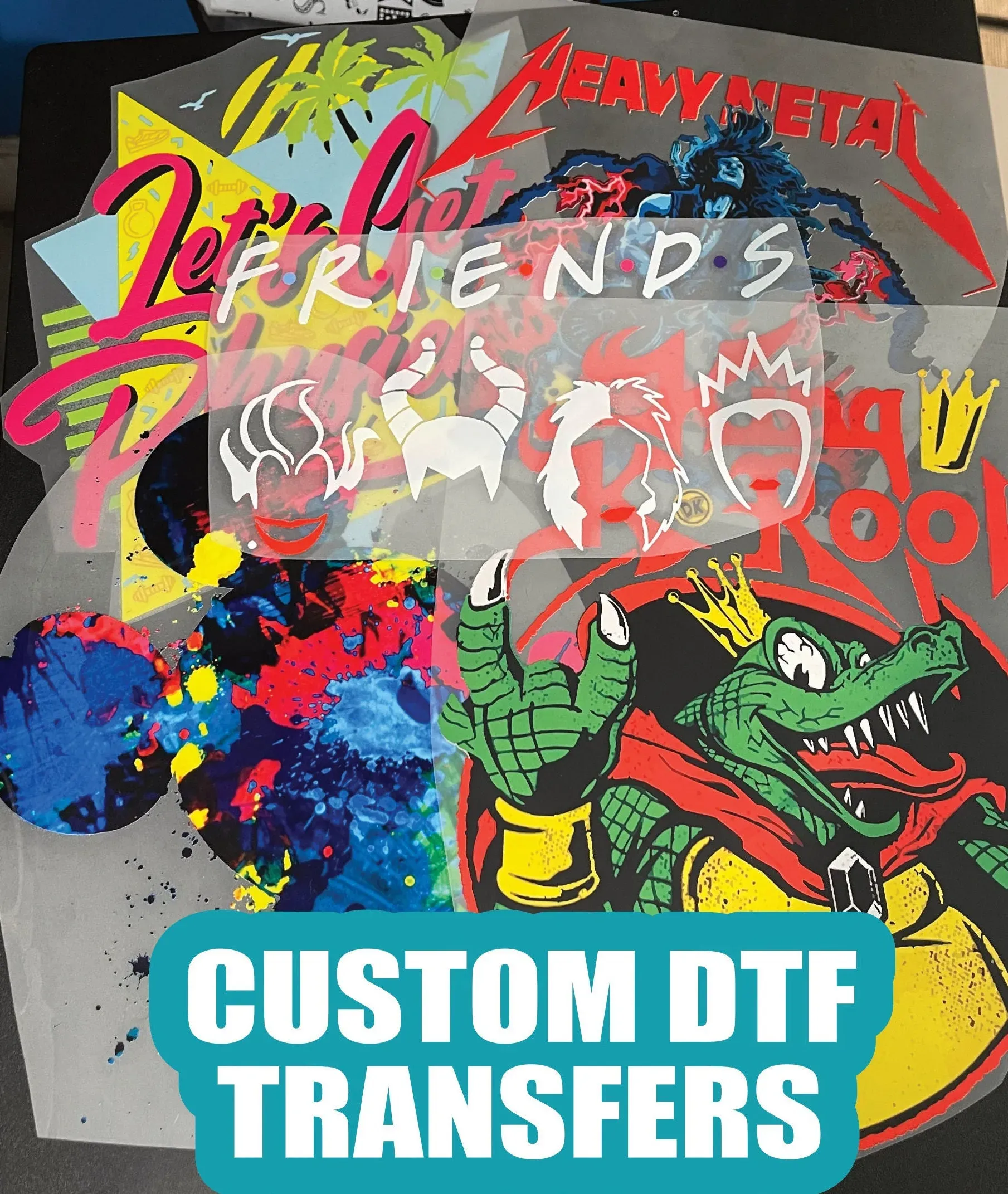

In the highly competitive world of DTF printing, standing out requires creativity. Print shops should embrace the versatility of DTF transfers by showcasing unique projects and innovative designs through their social media channels and online portfolios. Clients gravitate towards businesses that exhibit a passion for quality design and creativity. By posting high-quality images and videos of your work, customers can envision the possibilities that your DTF printing can offer.

Moreover, engaging with your audience through creative storytelling about your projects can enhance customer connection and trust. Highlighting successful collaborations and sharing the creative process cultivates a compelling narrative that attracts potential clients. When customers witness the dedication and creativity within your DTF prints, they are more likely to choose your print shop for their upcoming projects.

Frequently Asked Questions

What is DTF printing and how does it differ from traditional methods?

DTF printing, or Direct to Film printing, is a modern printing method that prints designs onto a specialized film before transferring them onto fabric using heat. Unlike traditional methods like screen printing, DTF allows for vibrant colors and intricate designs, making it compatible with various materials such as cotton and polyester. This process ensures high-quality prints that are durable and visually striking.

What equipment is essential for successful DTF transfers?

To achieve successful DTF transfers, investing in high-quality equipment is crucial. Recommended printers include reputable brands like Epson and Brother, as they offer reliability and performance. Additionally, using high-grade DTF films and powders is essential to ensure strong adhesion to fabrics and enhance the vibrancy of the prints.

How can I optimize the DTF printing process in my print shop?

Optimizing the DTF printing process involves several key steps. Ensure proper pre-treatment of fabrics when necessary for better adhesion, accurately cure the adhesive powder before applying heat to avoid quality issues, and calibrate your heat press for even heat distribution. Streamlining these processes enhances both efficiency and the overall quality of the DTF transfers.

What quality control measures should I implement for DTF transfers?

Implementing rigorous quality control measures at every stage of the DTF printing process is essential. After printing, inspect each transfer for vibrancy and adhesion before application, and consider testing a few prints in advance. This attention to detail minimizes errors and significantly enhances customer satisfaction and your business reputation.

What marketing strategies are effective for promoting DTF printing services?

To effectively market DTF printing services, focus on targeted marketing by identifying niches or demographics that may benefit from customized designs, such as local sports teams or small businesses. Use personalized marketing approaches and showcase innovative designs on social media platforms like Instagram and Facebook to engage potential customers and boost brand visibility.

Why is it important to showcase creativity in DTF transfers?

Showcasing creativity in DTF transfers is vital for attracting and retaining customers. By displaying unique projects and real-world applications of your DTF printing services on social media, you can illustrate the versatility and quality of your work. This not only enhances your brand’s visibility but also builds trust and interest among potential clients.

| Key Areas | Details |

|---|---|

| Understanding DTF Transfers | DTF printing technology involves printing designs onto a specialized film for transfer onto fabric, offering vibrant colors and compatibility across materials. |

| Investing in Quality Equipment | Utilizing high-quality printers and materials from reputable brands is crucial for achieving excellent print results. |

| Process Optimization | Enhance efficiency through pre-treatment, proper adhesive curing, and calibrated heat press operations. |

| Implementing Quality Control | Establish strict quality control measures to mitigate errors and enhance customer satisfaction. |

| Engaging Customers Through Targeted Marketing | Focus marketing on specific demographics and provide personalized approaches for better customer retention. |

| Showcasing Your Creativity | Utilize social media to display designs and success stories, which can enhance brand visibility and attract new clients. |

Summary

DTF transfers present an innovative approach for enhancing print shop operations and opening new avenues for creativity. With its ability to produce high-quality prints on various fabrics, DTF printing is a game-changer in the industry. The potential of DTF transfers goes beyond just technical processes; it encompasses diligent attention to quality, optimized operations, and strategic marketing. By adopting the strategies outlined in this guide, print shop owners can leverage the unique benefits of DTF transfers to captivate their audience and foster lasting relationships with customers. As demand for customization grows, mastering DTF printing can be your gateway to thriving in the competitive market.