DTF Transfers, or Direct to Film transfers, are revolutionizing the world of custom apparel printing, making it easier than ever for businesses to produce high-quality prints at a fraction of traditional costs. This innovative printing technique not only delivers vibrant designs and intricate details but also aligns with the increasing demand for sustainable printing solutions. As entrepreneurs and fashionistas alike delve into the realm of custom apparel, they are finding DTF printing to be an accessible and efficient option for their creative needs. Whether you’re looking to create unique merchandise or personalized clothing, DTF transfers present a cost-effective approach that caters to diverse consumer preferences. With its environmentally friendly process and potential for rapid market growth, DTF is paving the way for the future of the apparel printing industry.

In the dynamic landscape of garment printing, concepts like Direct to Film transfers are increasingly gaining traction, as they enable the production of custom apparel that meets modern consumer demands. This cutting-edge printing method offers a blend of quality, affordability, and sustainability that traditional techniques often struggle to provide. Custom design enthusiasts are now turning to this innovative approach for its ease of use and ability to produce high-resolution images without requiring substantial investment. As businesses strive to fulfill the growing desire for personalized clothing, alternative methods like film transfers are proving vital in addressing these changing needs. With a focus on eco-friendly practices and innovative technology, the custom printing sector is embracing the future offered by DTF solutions.

Understanding DTF Transfers for Custom Apparel Printing

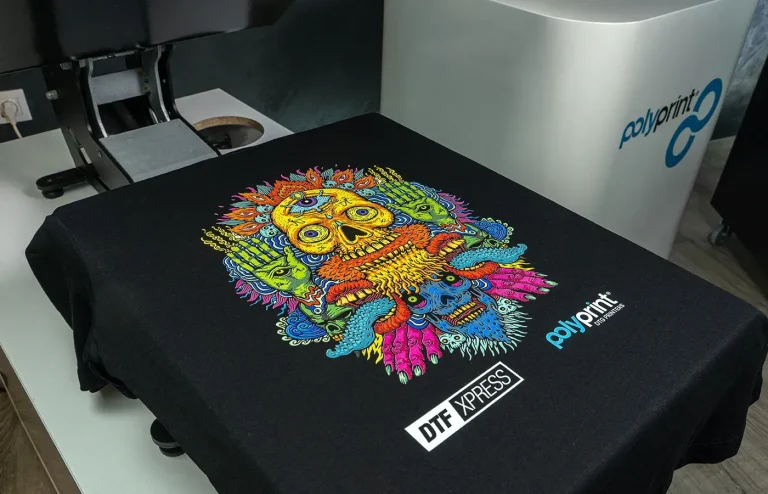

DTF Transfers, or Direct to Film Transfers, are rapidly becoming a favorite in the custom apparel printing world. This innovative method allows businesses to print high-quality designs directly onto a special film, which can then be heat-pressed onto clothing. The results are impressive, showcasing vivid colors and sharp details—qualities consumers demand in today’s market. As a result, more brands are pivoting to DTF printing to fulfill the increasing demand for unique and personalized apparel.

By utilizing DTF printing, custom apparel businesses can produce eye-catching designs on a variety of fabrics, including cotton and blends. This adaptability is crucial for tapping into niche markets and meeting specific customer requests. DTF transfers not only ensure the final product looks professional but also enable rapid production processes, catering to the fast-paced nature of consumer trends. With these advantages, DTF printing positions itself as a key player in the future of custom apparel.

The Cost-Effectiveness of DTF Printing

Cost-efficiency is a significant driving factor behind the adoption of DTF transfers in custom apparel printing. Traditional printing methods often come with high setup costs and minimum order requirements that make them prohibitive for smaller businesses or startups. DTF printing shifts this paradigm, allowing for smaller production runs without compromising on quality. This flexibility opens up opportunities for entrepreneurs to test designs and respond quickly to market demands with lower financial risk.

Moreover, with DTF sourcing affordable materials and resources, businesses can produce high-quality prints that are both economically viable and appealing to consumers. By streamlining the production process, DTF printing eliminates wasted resources, thus enhancing profitability. Consequently, businesses that embrace DTF transfers can not only meet customer expectations but also maintain a competitive edge in the increasingly crowded custom apparel market.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel printing?

DTF transfers, or Direct to Film transfers, involve printing designs onto a special film, applying an adhesive powder, and heat-pressing onto garments. This innovative process allows for high-quality prints on various fabric types, making it a popular choice for custom apparel.

Why are DTF transfers considered cost-effective for small businesses?

DTF transfers are cost-effective because they eliminate the need for high minimum order quantities and reduce setup costs compared to traditional printing methods. This accessibility makes it easier for small businesses to offer personalized products without incurring large expenses.

How do DTF transfers compare to traditional printing methods in terms of quality?

DTF transfers produce high-quality prints with vibrant colors and intricate details. Unlike traditional methods that may compromise on quality for complex designs, DTF ensures that every product meets customer expectations for custom apparel.

Are DTF transfers a sustainable printing option?

Yes, DTF transfers are a sustainable printing solution. They utilize water-based inks and generate less waste compared to traditional printing methods, making them an eco-friendly choice for businesses aiming to improve their environmental impact.

What advancements in technology support the growth of DTF printing?

The DTF printing market has seen significant technological advancements, including improved printers and supplies that increase output efficiency while lowering costs. These innovations help solidify DTF as a leading option for custom apparel printing.

How do DTF transfers cater to the consumer demand for customization in apparel?

DTF transfers effectively meet the rising consumer demand for customization by allowing businesses to create unique designs on demand quickly. This flexibility enables brands to respond to individual customer preferences, making DTF ideal for personalized apparel.

| Key Point | Description |

|---|---|

| High-Quality Prints | DTF printing delivers vibrant colors and high-resolution images, accommodating various fabrics for unique designs. |

| Cost-Effective Solutions | DTF is economical for small runs and complex designs, reducing setup costs and minimum order quantities. |

| Ease of Use | The simple process of DTF printing requires minimal technical training, allowing quick turnarounds in custom printing. |

| Sustainability | DTF printing uses water-based inks and minimizes waste, aligning with the demand for eco-friendly practices. |

| Market Growth and Technology Advancements | Innovations in DTF technology have boosted market growth, allowing printers to achieve more at lower costs. |

| Consumer Demand for Customization | DTF printing meets the increasing demand for personalization, enabling businesses to deliver unique designs rapidly. |

| Expansion Across Industries | DTF’s versatility allows applications beyond apparel, including merchandise and promotional items, expanding business opportunities. |

Summary

DTF Transfers are revolutionizing the custom apparel printing landscape, bringing together exceptional quality, affordability, and sustainability. This innovative printing technique excels in delivering stunning, personalized designs that resonate with today’s consumers. As businesses increasingly prioritize eco-friendly and cost-effective solutions, DTF transfers are emerging as the go-to choice for fulfilling the growing demand for customized apparel. In embracing these advances, brands can not only enhance their product offerings but also align themselves with consumer values, ensuring they remain relevant in a shifting market.