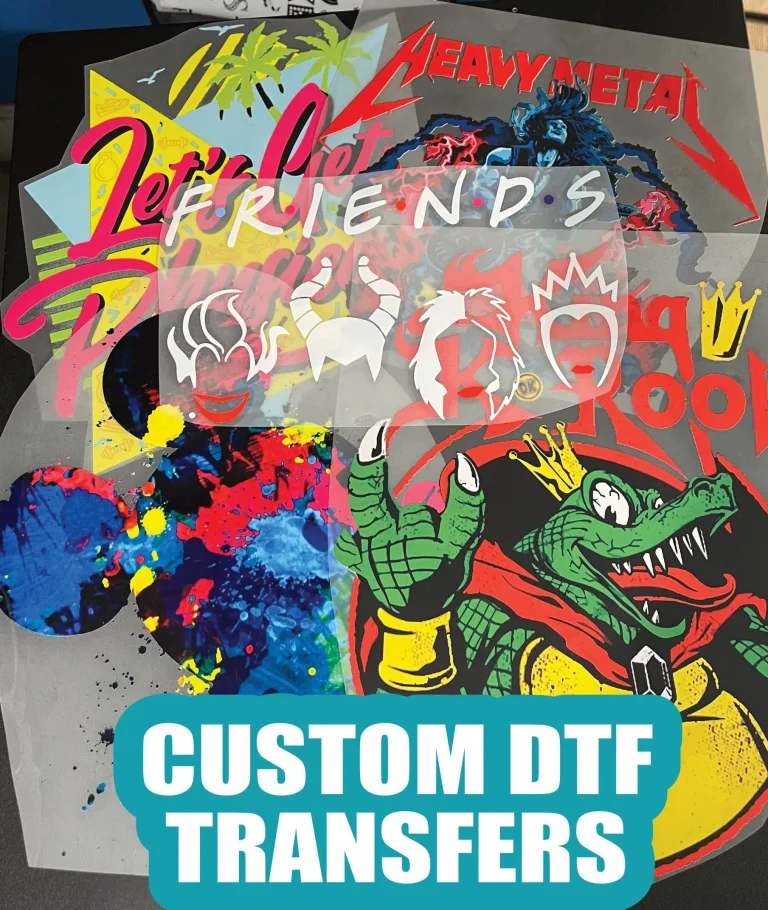

DTF transfers, or Direct to Film transfers, are revolutionizing the printing industry with their innovative approach to custom apparel production. This ground-breaking technology allows for vibrant images and intricate designs to be printed directly onto films, which can then be easily transferred to various fabrics with exceptional durability. As printing businesses embrace DTF technology, they uncover a myriad of benefits that enhance efficiency, reduce costs, and elevate print quality. With its ability to produce high-quality results rapidly, DTF transfers cater to the demands of designers and entrepreneurs looking to standout in the competitive custom apparel market. This blog post will explore how implementing DTF transfers can be a game changer for your printing business, offering new avenues for creativity and success in this ever-evolving landscape.

In the realm of custom printed fabrics, Direct-to-Film (DTF) transfer solutions are emerging as a formidable competitor to traditional methods. Also known as DTF printing technology, it specializes in transferring vivid colors and complex patterns onto diverse material types. This advanced process not only enhances the aesthetic appeal of garments but also supports businesses in meeting consumer expectations for quality and personalization. Small-scale enterprises and large printing houses alike are turning to this innovative printing approach as they expand their offerings and boost production efficiency. By leveraging DTF technology, print service providers can establish themselves as leaders in the burgeoning custom apparel sector.

Understanding DTF Transfers for Your Printing Business

Direct to Film (DTF) transfers represent a significant advancement in the printing technology landscape. This process involves printing designs onto a special film, which is then transferred onto garments using a heat press. The versatility of DTF printing makes it an excellent choice for a variety of applications, from custom apparel to promotional products. Its ability to produce vibrant, detailed prints sets it apart from traditional methods like screen printing, which can often limit color options and design complexity.

Moreover, DTF technology allows for exceptional durability, ensuring that prints remain intact even after multiple washes. This quality is particularly important for businesses looking to build a reputation for high-quality, long-lasting products. By understanding how DTF transfers work, printers can elevate their service offerings and attract a broader clientele, thereby capturing a larger market share.

The Advantages of DTF Technology for Custom Apparel Printing

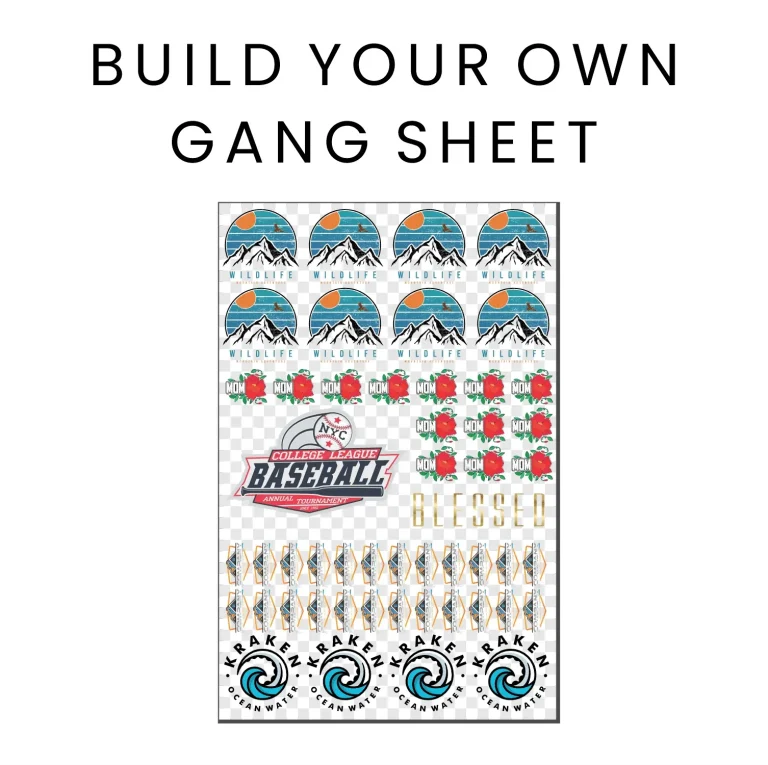

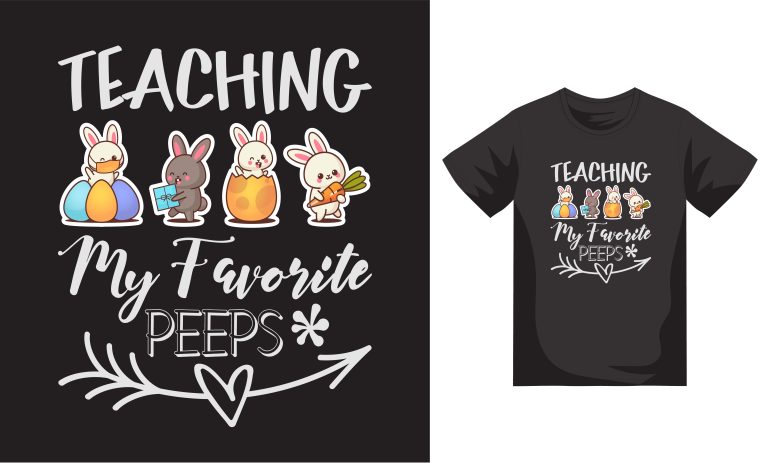

One of the primary benefits of utilizing DTF technology in custom apparel printing is its flexibility and ease of use. Printers can create vibrant designs that adhere well to various fabric types, including cotton, polyester, and blends. This opens up a world of opportunities for businesses, allowing them to cater to diverse customer preferences and fulfill unique orders. With DTF transfers, intricate designs and multicolor graphics can be printed effortlessly, enhancing the overall appeal of the final product.

Additionally, the DTF printing process is relatively straightforward, enabling quick turnaround times and lower capital investment. This efficiency can significantly benefit startups and small businesses, allowing them to maintain a competitive edge in a fast-paced market. As custom apparel continues to surge in popularity, the adoption of DTF technology positions businesses to capitalize on emerging trends and meet client demands effectively.

Cost Benefits of DTF Transfers in Printing Business Solutions

Cost-effectiveness is a major consideration for any printing business, and DTF transfers excel in this area. The initial investment in DTF technology is often much lower than traditional printing setups, such as screen printing, which requires expensive screens and setup each time a new design is produced. With DTF, companies can print directly from digital files, significantly reducing labor and material costs while maintaining quality output.

Moreover, DTF transfers enable businesses to minimize waste, as printing can be done on demand. This flexibility not only enhances profitability but also promotes sustainable practices within the printing industry. By embracing DTF technology, printing businesses can achieve efficiency and cost savings that empower them to grow and adapt to changing market demands.

Enhancing Printing Efficiency with DTF Technology

DTF transfers contribute to enhanced efficiency in printing workflows, allowing businesses to streamline their operations. By reducing the need for multiple setup processes, businesses can focus on producing high-quality prints faster. This speed is particularly advantageous during peak seasons when demand for printed products skyrockets. With DTF, printing operations can scale easily, accommodating larger orders without compromising quality or turnaround time.

Additionally, the simplicity of DTF technology means that it requires less training and fewer specialized skills compared to traditional printing methods. This makes it easier for businesses to hire and onboard new employees, maintaining a high level of productivity. As efficiency increases, so does customer satisfaction, leading to repeat business and a solid reputation in the market.

The Role of DTF Transfers in Supporting Small Businesses

In the competitive domain of custom printing, DTF technology plays a crucial role in supporting small businesses and entrepreneurs. The lower cost of entry for DTF printing systems empowers startups to offer high-quality products without the financial burden typically associated with traditional printing methods. This fosters a vibrant entrepreneurial ecosystem, allowing creative individuals to monetize their designs and offerings.

Moreover, DTF technology democratizes the printing industry by enabling a more diverse range of businesses to enter the market. Small businesses can leverage DTF transfers to create unique and personalized products that cater to niche audiences, enhancing their visibility and market reach. As a result, supporting small businesses not only contributes to economic growth but also enriches the overall printing landscape.

Future Trends in DTF Technology and Custom Printing

The future of DTF transfers and custom printing appears promising as technology continues to evolve. Innovations in DTF technology are likely to lead to even faster printing speeds and improved quality, enabling businesses to keep pace with consumer demand for personalized and unique products. As more manufacturers focus on developing user-friendly DTF printers, the barrier to entry will continue to decrease, inviting more players into the field.

Furthermore, as sustainability becomes increasingly important among consumers, DTF technology offers eco-friendly alternatives to traditional printing methods. The potential for waste reduction and the use of water-based inks can position DTF as a preferred option for businesses committed to sustainability. By keeping an eye on future trends, businesses can stay ahead of the curve and ensure they are well-positioned in the ever-evolving printing market.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, involve printing designs directly onto a special film using DTF technology. The printed film is then transferred onto fabric using heat and pressure. This method allows for vibrant colors and intricate details, making it ideal for custom apparel printing.

What are the benefits of DTF printing for small businesses?

DTF printing offers numerous benefits for small businesses, including cost-effectiveness, high-quality outputs, and the ability to produce intricate designs. The accessibility of DTF technology through affordable printers enables entrepreneurs to enter the custom apparel market without significant financial barriers.

How does DTF technology compare to traditional printing methods?

DTF technology surpasses traditional printing methods by offering a wider color spectrum, enhanced durability on various fabrics, and the ability to create detailed designs. This innovation allows printing businesses to expand their service offerings and better meet customer demands in custom apparel printing.

Can DTF transfers be used on all types of fabric?

Yes, DTF transfers are highly versatile and can be used on a variety of fabric types, including cotton, polyester, and blends. This flexibility makes DTF technology suitable for creating diverse custom apparel products, catering to a broad range of clients.

What equipment is needed for DTF printing?

To start DTF printing, you typically need a DTF printer, a heat press, DTF transfer film, and DTF inks. Affordable options like compact DTF printers have made it easier for small businesses to access high-quality printing solutions, making it an appealing choice for custom apparel entrepreneurs.

Is DTF printing suitable for high-volume production?

Yes, DTF printing is well-suited for high-volume production as it enables rapid printing of multiple designs and colors. The efficiency and quality of DTF technology help businesses scale their operations to meet growing demand, making it a robust solution for custom apparel printing.

| Key Points | Details |

|---|---|

| Innovation in DTF Technology | DTF transfers are revolutionizing the printing industry by offering vibrant colors and durable prints, enhancing both productivity and quality. |

| Accessibility and Quality | Tools like the LOKLiK iPrinter DTF enable small businesses to produce high-quality outputs without significant investment, fostering competition. |

| Expansion of DTF Services | DTF technology allows unlimited color printing and caters to various clients, expanding the range of services printing businesses can offer. |

| Support for Small Businesses | Affordable DTF printers support entrepreneurs and local communities, providing them with opportunities to thrive in the custom merchandise space. |

| Summary of Benefits | DTF technology is cost-effective, produces high-quality outputs, and expands market reach for printing businesses. |

Summary

DTF transfers are transforming the printing landscape by combining high-quality production with accessibility and innovation. The advantages of adopting DTF technology include cost savings, superior print quality, and the ability to cater to a broader audience, allowing businesses to thrive in a competitive market. As the industry evolves, integrating DTF transfers into your services not only enhances operational efficiency but also positions you to meet diverse customer demands. This technology is not just a trend; it’s a gateway to future-proofing your printing business, making it essential for newcomers and established entities to embrace its benefits wholeheartedly.