DTF transfers, or Direct-to-Film printing, have transformed the landscape of apparel printing with their innovative approach. This technology enables the creation of vibrant and detailed designs that can be applied to various fabrics, catering to the increasing demand for custom apparel. As businesses prioritize sustainable printing practices, DTF transfers stand out by minimizing waste while delivering exceptional quality. In this article, we will delve into the workings of DTF printing technology, its benefits, and its significant impact on the fashion industry. Join us as we explore how this remarkable printing method is reshaping the way we think about clothing and design.

Direct-to-Film printing represents a groundbreaking advancement in fabric decoration and personalization. This technique, often referred to as DTF transfers, allows for precise graphics to be seamlessly integrated onto textiles, making it a popular choice in the ever-evolving realm of clothing customization. With a focus on high-quality imagery and eco-friendly methods, this innovative fabric printing solution is leading the charge towards a more sustainable future in the apparel sector. As we venture into the details of this printing process, we will highlight its versatile applications and the benefits that make it a vital tool for designers and small businesses alike.

Understanding DTF Transfer Technology

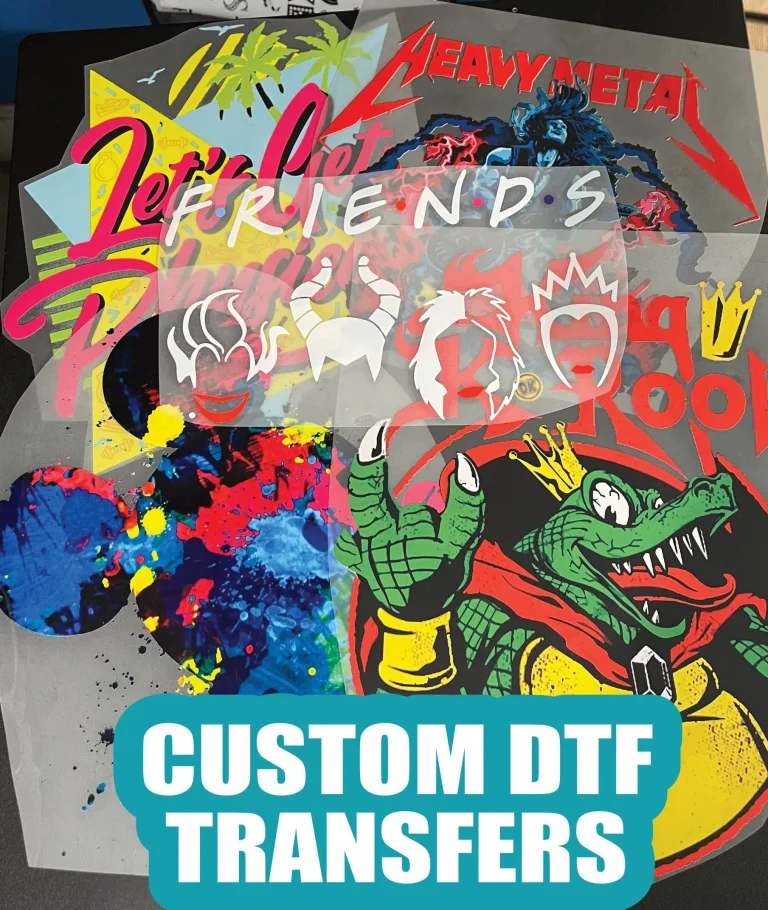

DTF transfer technology signifies a transformative leap in the realm of apparel printing, harnessing the power of heat and adhesive to infuse stunning graphics onto various fabrics. This innovative method is especially lauded for its ability to reproduce vibrant colors and intricate details that are often challenging to achieve with traditional printing methods. The versatility of DTF printing sets it apart, allowing for applications across an array of materials—including cotton, polyester, and their blends—making it a preferred choice for custom apparel.

What enhances the appeal of DTF transfers is the straightforward process of creating these prints. Designs are initially printed onto a specialized film coated with a heat-activated adhesive. When heat is applied during transfer, the design adheres seamlessly to the fabric, resulting in remarkably durable and lively prints. This method not only streamlines production but also caters to the increasing demand for efficient, high-quality apparel printing.

Benefits of DTF Printing for Custom Apparel

The advantages of DTF printing are manifold, particularly for businesses focusing on custom apparel. One of the foremost benefits is the high-quality output that this technology offers. DTF printing facilitates the creation of complex designs characterized by vivid color palettes and sharp detailing. As a result, apparel decorators can confidently tackle intricate patterns, logos, and artwork that would be difficult to reproduce through standard methods.

Moreover, the cost-effectiveness of DTF printing cannot be overstated. Compared to traditional processes, such as Direct-to-Garment (DTG) printing, DTF systems require a lower initial investment, making it accessible to small and medium-sized enterprises aiming to break into the apparel market. This democratization of printing technology empowers more creators and businesses to offer personalized, unique pieces to consumers while managing their budgets effectively.

Advancements Driving DTF Printing Innovation

The landscape of DTF printing is evolving rapidly, influenced by continual advancements in technology. Notably, manufacturers are investing in the development of new DTF printers that boast enhanced functionalities, such as faster print speeds and improved adhesion properties. These innovations are crucial for meeting growing consumer expectations for not only aesthetic quality but also durability, with prints designed to withstand frequent washing without fading or degrading.

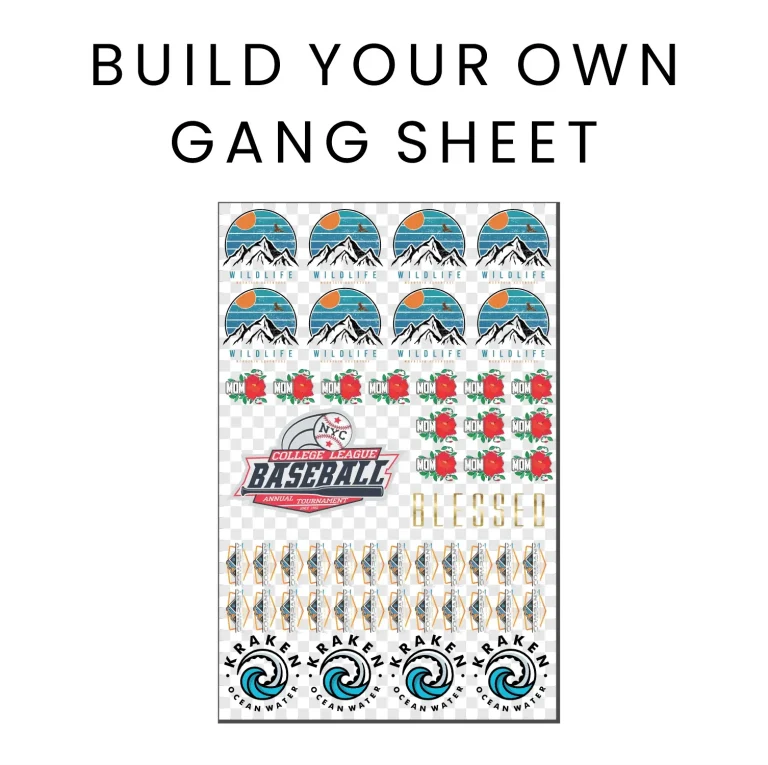

In addition, the recent surge in the adoption of DTF printing among small businesses can be attributed to its user-friendly nature. The integration of easy-to-navigate software has simplified the design-to-production workflow, allowing new entrants to quickly get up to speed with the technology. As a result, more entrepreneurs are leveraging DTF transfers to bring their creative visions to life, ultimately enriching the marketplace with diverse, high-quality custom apparel.

Sustainability in DTF Printing Practices

As the fashion industry increasingly embraces sustainable practices, DTF printing has surfaced as a more eco-friendly alternative compared to traditional methods. The ability of DTF technology to execute small runs of prints mitigates waste—a significant advantage in an industry known for its environmental impact. This makes DTF an appealing option for businesses seeking to align with eco-conscious consumers who favor brands that prioritize sustainability.

Furthermore, DTF printing’s lower setup requirements and minimal material waste make it conducive to on-demand production. When printers can swiftly fulfill small orders without the extensive resource commitments typical of bulk production, they not only conserve materials but also support a shift towards ethical fashion. Despite concerns about the environmental impact of some adhesives, ongoing innovations within the industry are focusing on developing greener options that further reduce DTF printing’s carbon footprint.

Getting Started with DTF Printing

Embarking on a DTF printing venture requires careful planning and the right toolkit. First and foremost, investing in a quality DTF printer is critical. Prospective printers should look for models that offer reliable performance and compatibility with various inks and films. Additionally, essential accessories such as heat presses and the appropriate inks should not be overlooked, as they are fundamental for achieving optimal results with DTF transfers.

Moreover, educating oneself about the DTF printing process is paramount for success. Aspiring printers can leverage the plethora of online resources, including tutorials and forums, to enhance their understanding of the technology. By mastering the technical aspects, including design selection and print execution, newcomers can better navigate the complexities of DTF printing, enabling them to innovate and explore their creative potential.

Market Trends Influencing DTF Printing Growth

The future of DTF printing is poised for significant growth, driven by shifting consumer preferences towards personalized and unique apparel options. As the market continues to evolve, trends suggest an increasing demand for customizable designs, which DTF printing can readily accommodate. This ability to produce distinctive pieces on-demand empowers consumers to express their individuality, making DTF printing an invaluable asset for businesses looking to attract a diverse clientele.

Additionally, analysts project a robust expansion for the DTF printing sector over the coming years, with expectations for a compound annual growth rate exceeding 10%. This prediction reflects the technology’s rising popularity in both niche markets and mainstream applications. As businesses recognize the potential of DTF printing to deliver high-quality custom apparel solutions while minimizing waste, investments in this area are likely to escalate, defining the future of textile printing.

Frequently Asked Questions

What is DTF printing technology and how does it work?

DTF printing technology, or Direct-to-Film printing, is a modern method for creating high-quality graphics on fabric. This process involves printing designs onto a special film, which is then coated with a heat-activated adhesive. When pressed onto the fabric at high temperatures, the design transfers smoothly, resulting in vibrant, durable prints suitable for various materials, including cotton and polyester.

What are the key advantages of using DTF transfers in apparel printing?

DTF transfers offer numerous advantages in apparel printing, including high-quality output with rich colors and intricate details. The technology is versatile, allowing for printing on both light and dark fabrics. Additionally, it is cost-effective compared to other methods like Direct-to-Garment (DTG) printing, making it accessible for small businesses. DTF printing also promotes sustainable printing practices by minimizing waste and facilitating small batch production.

Can DTF printing technology be used on different fabric types?

Yes, DTF printing technology is highly versatile and can be used on a wide range of fabric types, including cotton, polyester, and blends. This flexibility enables apparel decorators to create custom designs that cater to various styles and consumer preferences, making DTF transfers a popular choice in the fashion industry.

How does DTF printing compare to traditional screen printing methods?

DTF printing contrasts with traditional screen printing by eliminating the need for physical screens and reducing setup time. While screen printing is often better for large runs with few colors, DTF transfers excel in producing detailed, colorful designs with minimal waste, allowing for both large and small print runs. This efficiency and versatility make DTF printing a preferred method for custom apparel.

What should I consider when starting a DTF printing business?

When starting a DTF printing business, invest in quality equipment such as a reliable DTF printer, inks, and heat presses. Familiarize yourself with the DTF printing process through online tutorials and community resources. Experiment with various designs to showcase your creativity and understand your target market’s needs. Finally, promote your services through social media and local markets to attract customers.

What is the environmental impact of DTF printing and its sustainability benefits?

DTF printing technology is noted for its sustainability benefits, primarily due to its lower waste potential. By allowing small batch printing without extensive setup, DTF reduces material waste in comparison to other methods. However, it is essential to consider the environmental impact of some adhesives used in the process. Overall, DTF printing supports sustainable printing practices, aligning with the growing demand for eco-friendly fashion.

| Key Aspect | Details |

|---|---|

| DTF Transfer Technology | A process utilizing heat and adhesive to transfer graphics onto fabric, known for vibrant color and detail. |

| Advantages | High-quality output, versatility on different fabrics, cost-effective for small businesses, user-friendly, and supports sustainable practices. |

| Recent Developments | Increased market adoption, technical innovations improving speed and quality, sustainability concerns addressed, favorable market forecasts, and abundant tutorials for beginners. |

| Starting with DTF Printing | Invest in quality equipment, learn the process through online resources, experiment with designs, understand market needs, and promote your work effectively. |

Summary

DTF transfers are revolutionizing the apparel printing industry, offering innovative solutions that were previously unattainable. As businesses seek to meet the demands for quality and sustainability, DTF transfers provide a compelling answer with their vibrant output and adaptability. This technology not only enhances production efficiency but also supports creative ambitions, making it an optimal choice for modern printers. The continued growth in the adoption of DTF printing is set to bolster the apparel industry, providing endless opportunities for customization and creativity. Embracing DTF transfers will undoubtedly transform the landscape of apparel printing.