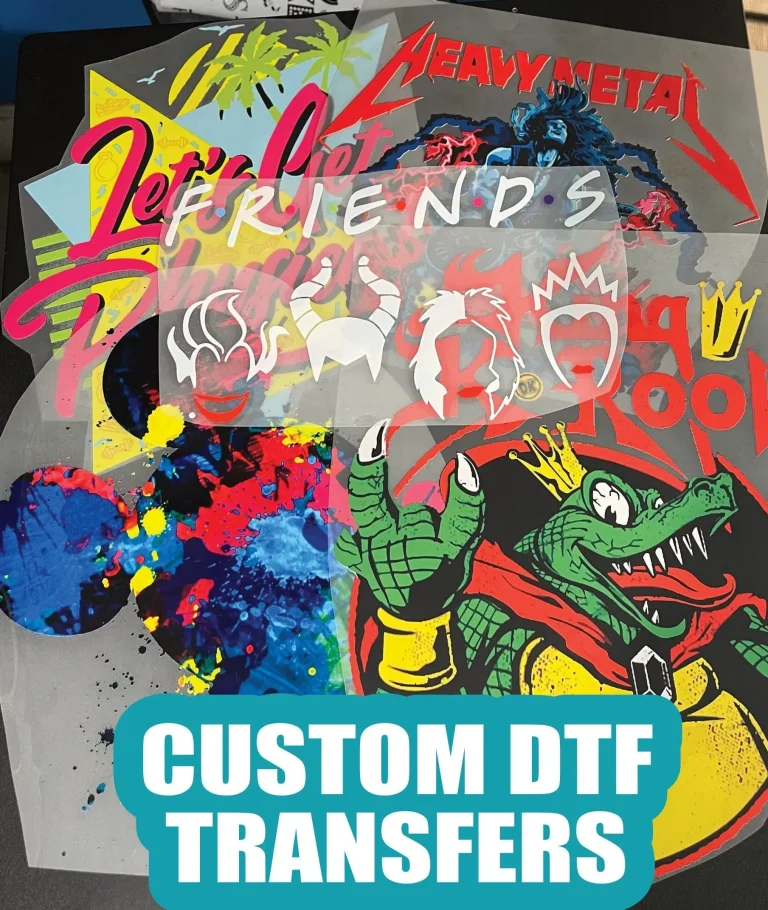

DTF transfers quality is the cornerstone of successful garment decoration. When you invest in direct to film transfers, you want crisp details that stay sharp wash after wash and colors that pop on any fabric, and that requires careful setup, calibration, and a disciplined color workflow. This guide breaks down the key factors behind high-quality DTF results and offers practical steps to achieve crisp details and vivid colors in every design, and it also highlights common pitfalls and quick checks you can perform before committing to a production run. Whether you are a small shop owner printing logos on T-shirts or a hobbyist exploring DIY transfers, understanding how each stage of the process affects final output will help you elevate your results and reduce costly reprints. From artwork and color management to heat-press optimization, a balanced workflow that accounts for fabric variety yields consistent, durable results that scale from one-off projects to large runs.

Viewed through alternative terms, the topic can be described as a film-to-fabric transfer process powered by pigment inks and heat. DTF printing techniques emphasize reliable color management, strong white underbases, and consistent adhesion to produce vibrant colors on textiles across light and dark fabrics. From that angle, practitioners optimize film selection, drying times, and curing profiles to protect edge sharpness and longevity. This framing also aligns with SEO and content strategies by connecting related ideas such as color management, fabric preparation for DTF, and press parameters into a cohesive picture.

DTF transfers quality: Key factors across artwork, printing, and curing

DTF transfers quality begins with artwork and file preparation. Start with high-resolution artwork; for raster images, 300 DPI at the final print size is a solid baseline, while vector logos scale without loss of detail. Proper color separation and avoiding over-compression preserve edges and reduce haloing around fine lines, aligning with best practices in DTF printing techniques. This ensures the final result delivers crisp print details and consistent DTF transfer quality across runs.

Beyond the artwork, material and process choices drive the outcome. Calibrate your printer with ICC profiles matched to your inks and film to achieve reliable color vibrancy; a well-defined white underbase improves opacity and color density. Use high-quality DTF film and inks, perform regular nozzle checks and head alignment, and fine-tune print settings (DPI, speed) to minimize edge blur and bleeding while maximizing crisp print details and overall DTF transfer quality.

Fabric preparation for DTF: Achieving crisp print details and vibrant colors on textiles

Pre-press garments to remove moisture and wrinkles, then apply any required pre-treatment evenly and allow it to dry completely. The fiber content, weave, and fabric color influence how ink sits on the surface, affecting vibrancy and sharpness. Thoughtful fabric preparation is foundational for delivering crisp print details and vibrant colors on textiles across different garment types.

Finish and post-processing validate the result. After transfer, cure fully and peel carefully to preserve edge integrity. Document results and monitor color consistency with test strips and ICC profiles, ensuring fabric preparation for DTF continues to deliver dependable, long-lasting DTF transfer quality with bright, durable colors on a variety of fabrics.

Frequently Asked Questions

What factors influence DTF transfers quality and how can I ensure crisp print details on textiles?

DTF transfers quality is shaped by several interdependent factors. Key elements include: – Artwork and file preparation: use high‑resolution artwork (300 DPI for raster, scalable vector for logos) with proper color separation to avoid halos and jagged edges. – Color management: calibrate your monitor and use ICC profiles tuned to your ink/film to keep crisp edges and accurate colors. – DTF film and white underbase: a strong white underprint and quality film improve opacity and edge contrast. – Inks and printer calibration: high‑quality inks and regular nozzle checks/alignments keep lines crisp. – Print settings and DPI: higher resolutions (600–1200 DPI) boost edge definition, within your printer’s capabilities. – Heat press and curing: correct temperature, time, and pressure ensure stable adhesion and color maturity. – Fabric preparation for DTF: pre‑press to remove moisture and use appropriate pre‑treatment to anchor the transfer. Following a consistent workflow and testing on target fabrics will help preserve crisp print details across runs.

How can I achieve vibrant colors on textiles while maintaining DTF transfers quality across batches?

Achieving vibrant colors on textiles without compromising DTF transfers quality relies on deliberate color management and material choices. Key practices include: – Color management discipline: implement screen‑to‑print calibration with ICC profiles for your ink/film combo to reproduce saturated reds, greens, and blues reliably. – Underbase strategy: a robust white underprint preserves color density, especially on dark fabrics. – Film and ink balance: adjust ink density, print speed, and film translucency to maintain color richness without oversaturation. – Fabric interaction: account for fabric color and weave; use stronger white underbase for dark garments to keep brightness on light fabrics. – Finishing steps: proper cooling and careful peeling after transfer help lock in color and prevent migration. – Practical workflow: use test strips, verify color accuracy before production, and document settings for consistency across batches.

| Aspect | Key Points |

|---|---|

| Artwork and file preparation | Start with high‑resolution artwork ( raster: 300 DPI at final print size; vector logos scale without detail loss). Ensure proper color separation and avoid over‑compression to preserve edges and reduce haloing. |

| Color management and ICC profiles | Use consistent color management. Calibrate your monitor and use printer ICC profiles tailored to your DTF ink set and film to ensure reliable color vibrancy across runs. |

| DTF film and white underbase | Film quality and white underbase dramatically affect opacity and color density. A strong white underprint provides a clean canvas and prevents fabric color from bleeding into the design. |

| Inks and printer calibration | Use high‑quality white and color inks, with a well‑maintained printer. Regular nozzle checks, head alignment, and cleaning routines keep lines crisp and colors accurate. |

| Print settings and DPI | Print at higher resolution (commonly 600–1200 DPI for DTF) to improve edge definition and detail resolution. DPI depends on printer, film, and design complexity. |

| Heat press parameters and curing | Temperature, time, and pressure determine how well the film adheres and how colors mature. Too little heat/time can fade colors; too much heat can cause bleeding or fabric damage. |

| Fabric type and preparation | Fiber content, weave, and pre‑treatment influence ink sit on the surface. Pre‑press to remove moisture and use pre‑treatment when required to anchor the transfer. |

| Crisp details: artwork optimization | Use vector outlines where possible; for raster designs, ensure edges are clean and high‑resolution to minimize jagged lines. |

| Crisp details: white underbase & color separations | Build a solid white layer beneath color areas; proper color separations and limited over‑printing help edges stay sharp. |

| Achieving vivid colors: color management discipline | Calibrate steps from screen to print with ICC profiles tuned to your ink and film to reproduce saturated colors across fabrics. |

| Achieving vivid colors: underbase strategy | A well‑built white underbase reveals true color density and helps unlock brighter blues and reds on various fabric tones. |

| Achieving vivid colors: film, ink balance & fabric interaction | Balance film translucency and ink density; adjust density, speed, or film to preserve vibrancy on different fabrics. |

| Finishing steps & fabric interaction | Post‑press cooling, careful peeling, and protective finishing help preserve color; avoid aggressive handling until set. |

| Practical workflow to maximize DTF transfers quality | Pre‑press and fabric prep; file and color prep; printing discipline; transfer and curing; QA and documentation for consistency. |

| Troubleshooting common issues | Fading after washing, color bleeding, blurred outlines, white gaps, or poor adhesion—apply targeted fixes like adjusting heat/time, underbase density, or curing. |

| Maintenance, testing, and ongoing improvement | Regular printer maintenance, color calibration, production QA, and record keeping to sustain quality across runs. |

Summary

DTF transfers quality is a cornerstone of modern garment decoration. By focusing on artwork readiness, material selection, printer calibration, and precise heat application, you can achieve crisp details and vivid colors that endure wash and wear. A repeatable workflow with prepress, color management, test prints, and quality checks helps maintain high DTF transfers quality across batches and fabrics. With ongoing refinement, your designs will stand out in a crowded market.