DTF transfers have surged in popularity as a flexible, vibrant option for customizing apparel and merchandise. If you’re exploring heat-applied designs for T-shirts, hoodies, bags, or athletic wear, this guide outlines what you need to know. It explains what these transfers are, the main advantages and drawbacks, and how they stack up against other methods such as screen printing. You’ll discover practical factors that influence quality, cost, and durability when choosing a method. The section also covers the transfer process, working with a heat press, and best practices to maximize wash durability and the overall appearance.

In other terms, this approach is often described as direct-to-film printing. Also known in shorthand as DTF printing, it relies on a specialty film and adhesive to transfer designs to fabrics. From an LSI perspective, you can think of it as a film-based transfer that emphasizes color fidelity, durability, and fabric versatility. This framing helps readers compare heat-press parameters and post-press care without getting lost in vendor jargon. By using alternative terms and related concepts, brands and hobbyists can connect to broader discussions about film-to-fabric transfers and durable finishes. This broader framing helps readers compare options with other methods in terms of practical outcomes, such as design fidelity, cost efficiency, and wash performance.

DTF Transfers: A Flexible, High-Resolution Solution for Apparel

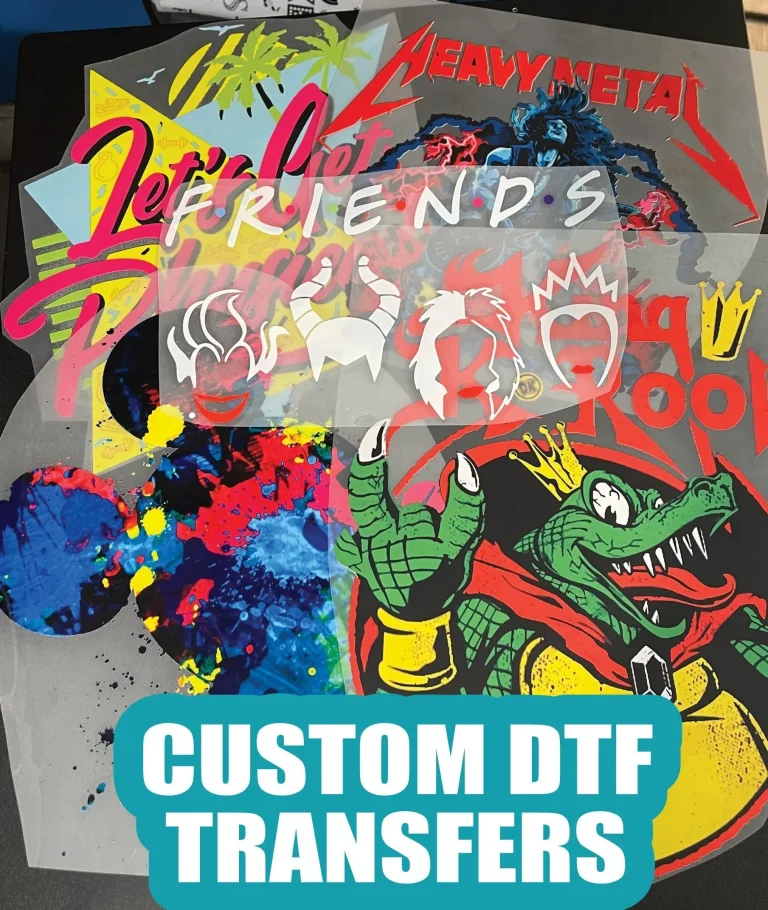

DTF transfers offer a flexible, vibrant option for customizing apparel and merchandise. The DTF transfer process starts with printing designs onto a special film using water-based pigment inks, followed by applying a powder adhesive, curing, and then transferring the image to fabric with a heat press for DTF. This workflow yields high-resolution, detailed color and strong adhesion across materials like cotton, polyester, and blends. Leveraging DTF printing in this way helps you reproduce gradients and fine lines with clarity that compares favorably to other modern methods.

Benefits include fabric versatility and no need for screen setups for each design, enabling small runs or on-demand production. The color reproduction is sharp, with gradients and intricate details preserved, and the finish can be soft and flexible when applied correctly. DTF transfers can be a cost-effective option for short runs compared with traditional screen printing, especially when design changes are frequent. With proper care—the right film, adhesive, and heat-press calibration—the wash durability of DTF tends to be solid across common fabrics.

DTF vs Screen Printing: How to Decide and Maximize Results

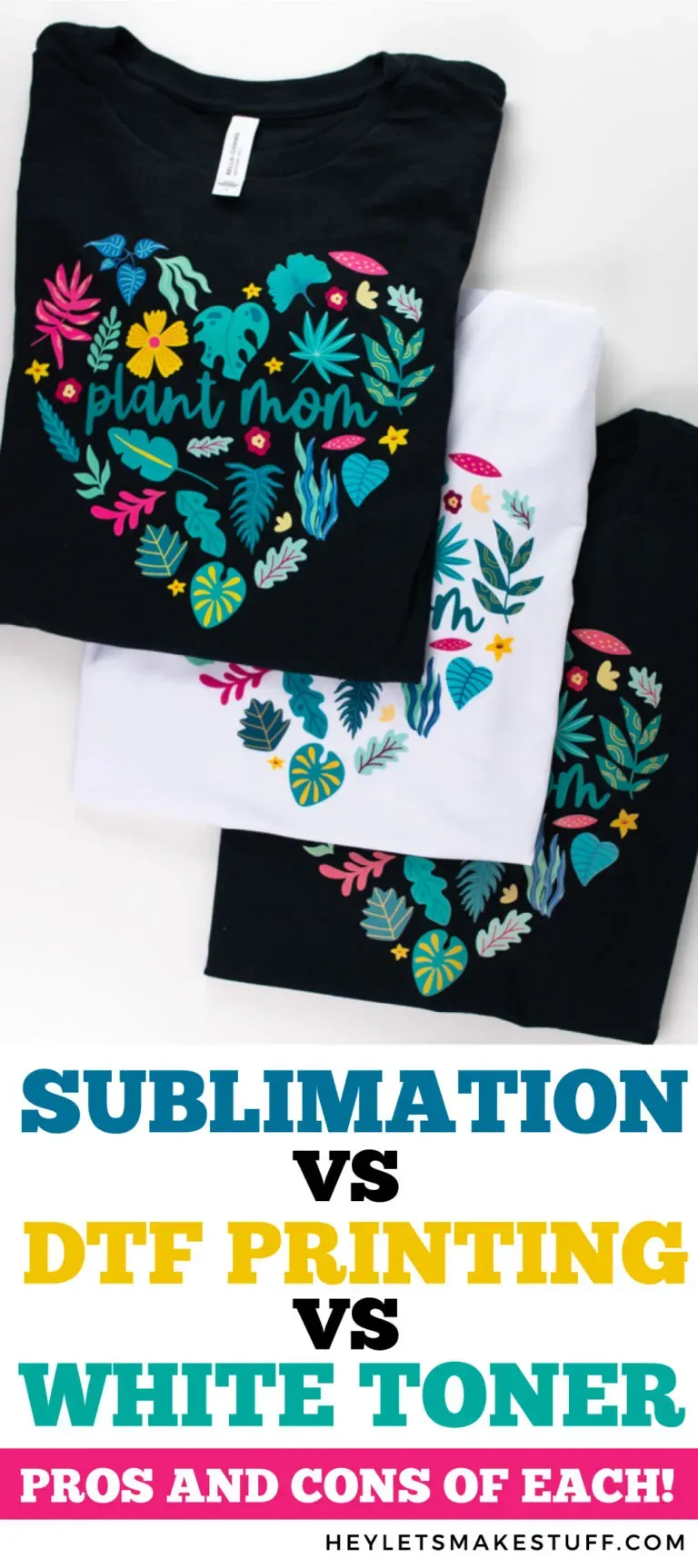

When deciding between DTF vs screen printing, consider design complexity, run size, fabric, and budget. For designs with many colors, subtle gradients, or photographic elements, DTF printing often provides superior color fidelity without the setup overhead of multiple screens. For very small runs or on-demand prints, DTF transfers can be more economical due to lower upfront tooling, while large-volume production may favor screen printing for lower per-unit costs. DTF transfer process nuances and fabric compatibility further influence the choice, as DTF adheres well to a wide range of fabrics, including cotton, polyester blends, and some non-traditional materials.

To maximize results, invest in quality film, inks, and adhesives from reputable suppliers, and ensure your heat-press equipment is properly calibrated. Key considerations include pre-pressing to smooth the fabric, selecting appropriate temperature and dwell times, and maintaining even pressure across the design. For long-term performance, follow care guidelines to improve wash durability of DTF, such as turning garments inside-out, washing in cool water, and avoiding harsh chemicals that can degrade adhesives or inks.

Frequently Asked Questions

DTF transfers vs screen printing: how does the DTF transfer process compare, and when should you choose DTF over traditional screen printing?

DTF transfers involve printing designs on a special film with a heat-activated adhesive and using a heat press to transfer the image to fabric, delivering high color fidelity and fabric versatility. They’re advantageous for small runs, on-demand work, and multicolor designs because setup is minimal compared with screen printing. Large-volume production can favor screen printing due to lower per-unit costs, depending on design and color count. For the transfer process, use a heat press at about 305-325°F (150-165°C) for 10-15 seconds with even pressure, then allow to cool and follow the adhesive’s curing guidelines to maximize durability.

How can you maximize wash durability of DTF transfers and ensure long-lasting performance?

Start with quality materials and proper application: pre-press to flatten the fabric, apply the DTF transfer with correct temperature, time, and pressure, then let it cool. To preserve wash durability, turn garments inside-out, wash in cold or warm water on a gentle cycle, and either air-dry or use a low-heat dryer. Avoid chlorine bleach and harsh cleaners, and always follow the adhesive and film manufacturer’s care guidelines for best results.

| Topic | Key Points |

|---|---|

| What are DTF transfers? |

|

| Pros of DTF transfers |

|

| Cons of DTF transfers |

|

| DTF transfer process: how it works |

|

| DTF vs screen printing: when to choose which |

|

| Heat press considerations for DTF |

|

| Wash durability and care tips |

|

| Cost considerations and practical use cases |

|

| Use cases and best practices |

|

Summary

Conclusion: DTF transfers offer a compelling combination of color fidelity, material versatility, and production flexibility, making them a strong choice for many apparel projects. By understanding the transfer process, optimizing heat-press settings, and following care guidelines to boost wash durability, you can achieve reliable results across a range of fabrics and applications. Whether you’re comparing DTF transfers to DTF printing workflows, weighing the pros and cons, or deciding between DTF and screen printing, informed decisions and careful execution will help you deliver standout products that meet customers’ expectations and stand up to regular wear and washing.