DTF transfers have reshaped how designers approach apparel customization, delivering vibrant color, flexibility, and surprising durability. As you explore options for tees, hoodies, or bags, you’ll find that DTF printing combines film-based versatility with robust adhesion. This article introduces how the process works, debunks common myths, and shares practical heat press tips for getting consistent results during the heat-press stage. You’ll also see how DTF vs heat transfer stacks up against other methods, including sublimation as a viable sublimation alternative, helping you weigh pros and cons for different fabrics. With a focus on durability of DTF transfers and care, this guide highlights steps to maximize color fidelity and longevity across fabrics.

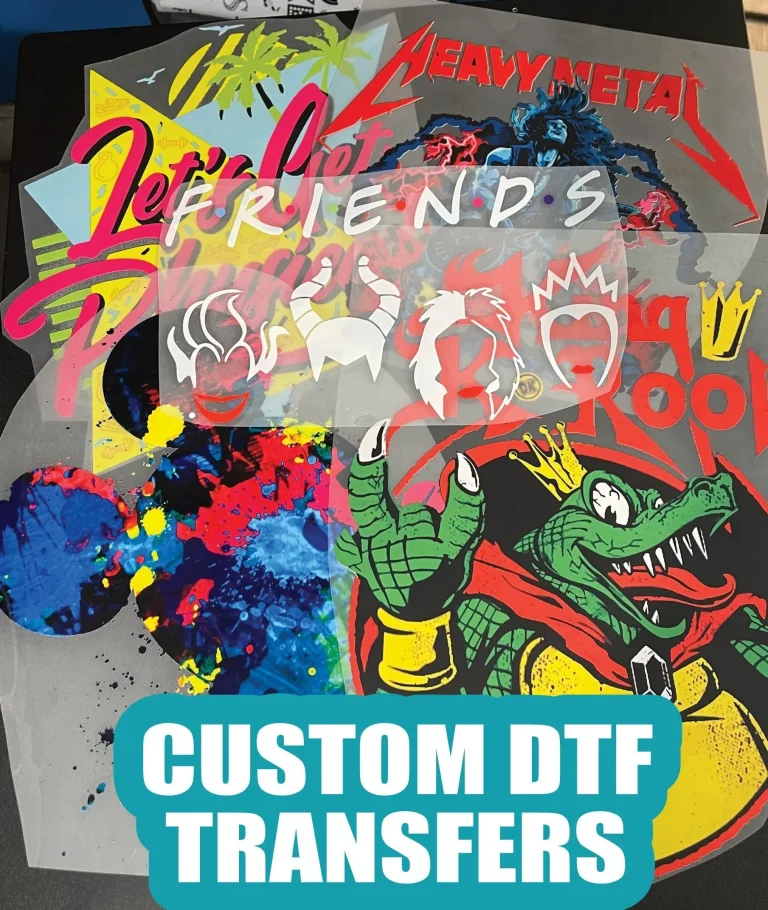

A film-based garment decoration method prints designs onto a carrier film, then applies heat and pressure to fuse the image onto fabric. Often framed as a modern alternative to DTG and traditional heat transfers, this technique relies on an adhesive powder and a curing stage to secure vibrant edges. From a material-agnostic perspective, the workflow centers on graphics-to-film production, powder coating, and a precise heat-press cycle. For brands prioritizing color brightness, fabric compatibility, and scalability, evaluating this approach against sublimation alternatives and other transfer options reveals practical trade-offs.

DTF Transfers Unpacked: How DTF Printing Works, Durability, and the Sublimation Alternative

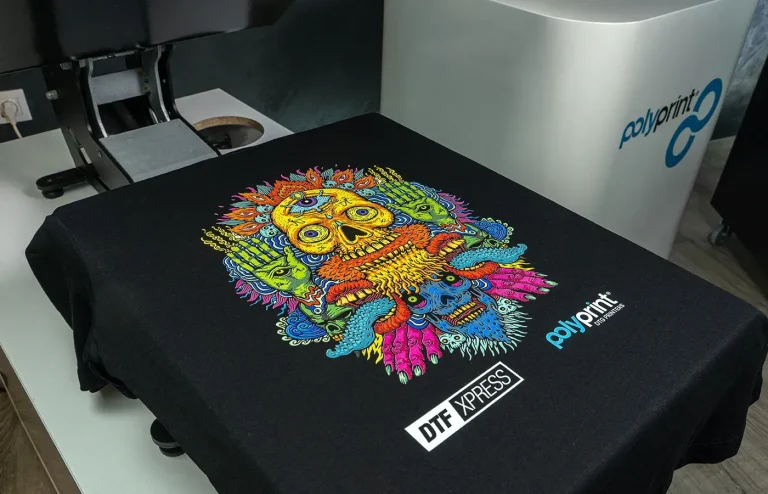

DTF printing starts with artwork designed in a graphics program and printed onto a specialized film using water-based inks. After printing, an adhesive powder is evenly applied and cured, creating a ready-to-transfer film. When heat and pressure are applied, the adhesive activates and bonds the design to the fabric. This workflow—design, film print, adhesive, cure, then heat press—embodies the DTF transfers process and sets it apart from direct-to-garment (DTG) printing, where the art goes directly onto the garment.

DTF transfers offer high color fidelity, crisp edges, and broad fabric compatibility, including cotton and blends. The durability of DTF transfers is a key advantage, making them a strong option for longevity in real-world wear and washing. Because the process can create a white underlay on dark fabrics and maintain vibrant color across varied textures, many designers view DTF as a sublimation alternative that expands the range of printable materials beyond polyester-heavy substrates.

In practice, this method scales from single-item prototypes to small batches without the setup costs associated with screen printing. Proper curing and film quality are essential to maximize durability, while careful garment preparation and heat-press parameters ensure consistent results across runs. With thoughtful design and process control, DTF transfers can deliver durable, high-quality results suitable for everyday wear and promotional products.

DTF vs Heat Transfer: Practical Comparisons, Heat Press Tips, and Real-World Outcomes

When weighing DTF transfers against traditional heat transfer methods, you’ll notice differences in edge sharpness, color vibrancy, and texture. DTF transfers typically produce crisper edges and smoother color gradients, with a softer hand on the fabric when applied correctly. This makes DTF a compelling option for multi-color designs and complex graphics, and it positions DTF as a strong alternative to other heat transfer sheets in terms of durability and wash performance.

To maximize success with DTF printing, follow practical heat press tips: aim for 320–350°F (160–177°C), press for about 12–20 seconds depending on fabric thickness and ink formulation, and apply medium to firm pressure (roughly 40–60 psi). Some films require a hot peel, while others need a cold peel, so always follow the film manufacturer’s instructions. Pre-press the garment to remove moisture and post-press briefly to improve adhesion and reduce soft-hand on certain fabrics.

In real-world use, DTF transfers prove particularly effective for small runs, custom merch, and applications where you need full-color designs on a wide range of fabrics. The durability of DTF transfers under washing conditions is a common point of comparison with sublimation and DTG, and many brands choose DTF as a viable sublimation alternative when dark fabrics or cotton blends are involved. With proper care—turning garments inside out, washing on gentle cycles, and avoiding high heat drying—DTF designs can maintain color, adhesion, and readability across many washes.

Frequently Asked Questions

DTF transfers vs heat transfer: what are the key differences and is DTF printing more durable?

DTF transfers (DTF printing) involve printing artwork onto a film, applying adhesive powder, curing, and then heat-pressing the film onto fabric. Compared with traditional heat transfer sheets, DTF transfers typically offer crisper edges, richer color, and better adhesion across a wider range of fabrics, including cotton blends. When properly cured and pressed at recommended temperatures and times, DTF transfers deliver strong wash durability that can rival other modern methods. For best results, use quality film and follow heat press tips such as correct pressure, temperature, and peel method.

Is DTF transfers a good sublimation alternative, and what heat press tips ensure durable results on diverse fabrics?

Yes—DTF transfers can be an effective sublimation alternative on fabrics where sublimation is impractical (such as many cotton blends). DTF works on a broader range of materials and colors, including dark garments, thanks to the white underbase. To maximize durability, follow heat-press tips: select appropriate temperature (often around 320–350°F / 160–177°C), dwell time (12–20 seconds), and consistent pressure; ensure proper curing of the adhesive powder; and cure and wash according to guidelines to preserve color and adhesion.

| HTML Table | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

“}]} , |

||||||||||||||||||||

|

DTF transfers provide a versatile, color-rich option for modern apparel printing, blending broad fabric compatibility with scalable production. This overview highlights how DTF works, debunks common myths, and shares practical tips for design, curing, and heat-press settings. Real-world applications—from custom tees to promotional items—demonstrate DTF’s adaptability and durable results on both light and dark fabrics. By optimizing workflow, color management, and garment care, brands can maximize the longevity and vibrancy of DTF transfers across small orders or large runs. For makers and brands seeking flexible, cost-effective prints, DTF transfers stand out as a robust tool in the contemporary printing toolkit. “}] } ] , |

||||||||||||||||||||

| DTF transfers offer a versatile, color-rich option for modern apparel printing, blending broad fabric compatibility with scalable production. This overview highlights how DTF works, debunks common myths, and shares practical tips for design, curing, and heat-press settings. Real-world applications—from custom tees to promotional items—demonstrate DTF’s adaptability and durable results on both light and dark fabrics. By optimizing workflow, color management, and garment care, brands can maximize the longevity and vibrancy of DTF transfers across small orders or large runs. For makers and brands seeking flexible, cost-effective prints, DTF transfers stand out as a robust tool in the contemporary printing toolkit. |

Summary

DTF transfers offer a versatile, color-rich option for modern apparel printing, blending broad fabric compatibility with scalable production. This overview highlights how DTF works, debunks common myths, and shares practical tips for design, curing, and heat-press settings. Real-world applications—from custom tees to promotional items—demonstrate DTF’s adaptability and durable results on both light and dark fabrics. By optimizing workflow, color management, and garment care, brands can maximize the longevity and vibrancy of DTF transfers across small orders or large runs. For makers and brands seeking flexible, cost-effective prints, DTF transfers stand out as a robust tool in the contemporary printing toolkit.