DTF transfers, or Direct to Film transfers, have become a game-changer in the custom apparel industry, allowing creators to print stunning designs with remarkable precision. This innovative printing technique leverages specially formulated inks and a transfer film to produce vivid, long-lasting images that adhere well to various fabrics. As interest in personalized clothing continues to grow, understanding how to DTF transfer can elevate your creative projects, whether you’re a small business or a DIY enthusiast. The DTF printing process not only simplifies the creation of intricate graphics but also enhances the durability of your final products. In this guide, we’ll explore how to master DTF transfers and dive into the essentials of effective design application and execution.

Direct to Film transfers represent a cutting-edge method of printing that’s quickly gaining traction among apparel decorators. This technique utilizes a unique combination of ink and specialized film to produce high-quality prints that stand the test of time. Those exploring how to implement direct-to-film applications will find that this process affords a versatile approach to transferring images, beautifully adapting to various types of fabric. Whether you’re interested in crafting custom shirts or other clothing items, mastering the DTF printing process is essential to achieving vibrant and detailed designs. With this comprehensive guide, you’ll be well-equipped to navigate the nuances of DTF printing and elevate your apparel designs.

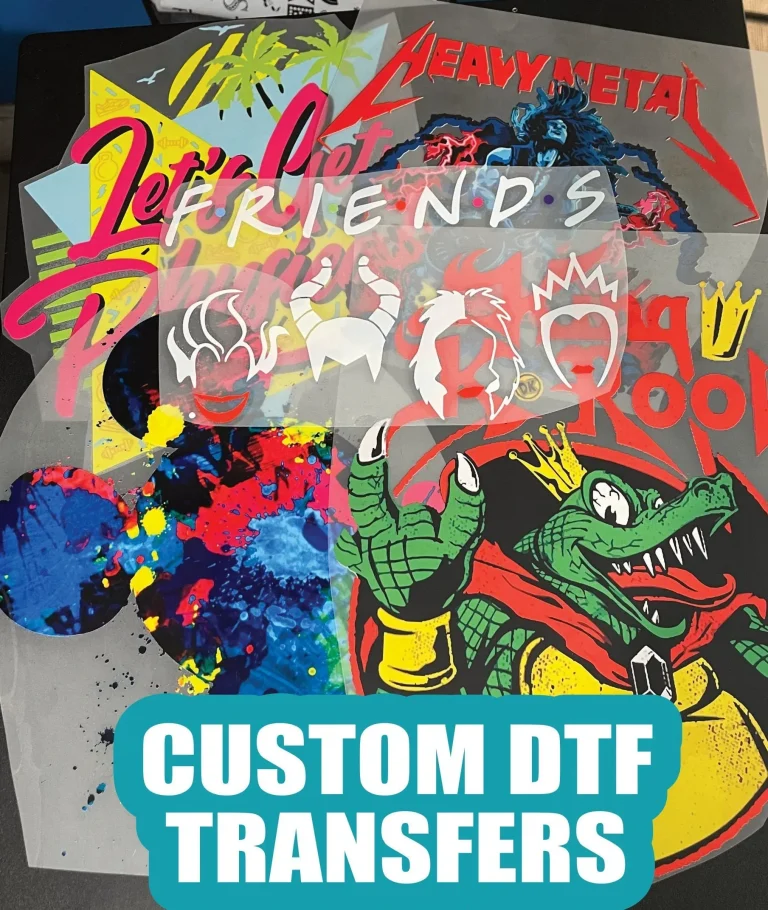

Understanding the Fundamentals of DTF Transfer Printing

DTF transfer printing is a modern technique that allows creators to produce intricate, high-quality designs suitable for various fabric types. By utilizing a specialized ink layered onto film, this method provides exceptional color vibrancy and durability, appealing to both custom apparel enthusiasts and professional businesses. The process shines in its versatility, enabling users to easily create detailed graphics that capture the eye, step by step, from design to application.

One of the key advantages of the DTF printing process is its enhanced practicality compared to traditional methods such as screen printing. Unlike those older techniques, DTF transfers facilitate quick turnaround times, making them an ideal choice for businesses looking to meet high demand. Understanding the fundamentals of DTF transfers not only enables creators to produce unique designs but also positions them strategically in an increasingly competitive custom apparel market.

Step-by-Step Process to Creating Stunning DTF Transfers

Creating stunning DTF transfers begins with a well-crafted design. It is essential to utilize professional graphic design software, such as Adobe Illustrator or CorelDRAW, which provides robust tools for creating vibrant, high-resolution artwork. Designers should focus on color accuracy by using the CMYK color profile, which is compatible with the DTF printing process. Additionally, remember to mirror your design before printing, ensuring optimal adherence to fabric.

After finalizing the imaginative designs, the next steps include careful printing onto DTF film. Selecting the correct DTF printer and optimizing print settings are crucial for success. Ensuring high print quality and correct ink usage can dramatically improve the final outcome. With a meticulous approach to the entire printing process, you can master DTF transfers effectively and produce eye-catching apparel.

Mastering the Powder Adhesion Technique in DTF Transfers

Powder adhesion is a crucial step in the DTF transfer process, directly impacting the quality and durability of the finished product. After printing your design onto the DTF film, promptly sprinkle hot melt powder over the wet ink. This powder acts as a bonding agent, facilitating a strong connection between the ink and the fabric when heat is applied. Properly layering the powder ensures a smooth adhesion and prevents any peeling of the design post-transfer.

After applying the powder, curing it with a heat source is paramount. This stage transforms the powder into a solid binding layer that connects your intricate designs to the fabrics. Utilizing consistent heating techniques, whether through curing ovens or heat presses, ensures that the adhesion layer is appropriately melted. Mastering the powder adhesion technique is foundational in producing high-quality DTF transfers that withstand the test of time and wear.

The Importance of Heat Transfer Specifications

Heat transfer plays a vital role in executing successful DTF transfers, as it is the stage where the design permanently adheres to the fabric. It is important to preheat your heat press to the temperature recommended for DTF transfers, typically between 160-180 degrees Celsius. Setting the correct pressure is equally critical to ensure an even application of heat and that your design adheres correctly without damage.

Applying firm pressure for the appropriate time, generally between 15 to 30 seconds, will optimize the transfer effectiveness. Skipping this step or applying insufficient heat can lead to subpar results, such as lifting edges or loss of vibrancy. By adhering to the specified heat transfer parameters, you can guarantee crisp, professional-looking DTF designs that appeal to a wide market.

Tips for Maintaining Quality in DTF Printing

To maintain quality in DTF printing, consistently use high-grade materials such as quality DTF films, pigmented inks, and reliable heat presses. Investing in these materials can significantly elevate the end results, making your designs more vibrant and durable against wear and tear. Be vigilant about the condition of your printing equipment, regularly calibrating your printer and heat press to ensure optimal function and quality control.

Experimentation is beneficial in the DTF transfer process. Trying out different fabric types and printer settings can help you discover the ideal combinations that work best for your specific designs. Keep up with the latest developments in DTF technology and materials on the market, as this knowledge will empower you to refine your methods and produce top-notch work consistently.

Exploring Recent Innovations in DTF Transfer Technology

Recent innovations in DTF transfer technology have significantly improved the printing landscape, focusing on quality enhancement and sustainability. New formulations of inks are being developed that increase durability and softness, making DTF transfers ideal for daily wear apparel. Innovations are aiming at providing smoother textures without compromising color vibrancy, which is essential for custom fashion.

Moreover, an eco-conscious shift is emerging within the DTF printing industry, with more manufacturers offering environmentally friendly inks and films designed to cater to the modern consumer’s preferences. Staying informed about these advancements not only helps businesses appeal to environmentally conscious customers but also positions them to take advantage of the evolving market trends.

Frequently Asked Questions

What is the DTF printing process and how does it work?

The DTF printing process involves using Direct to Film (DTF) transfers to print high-quality images onto a film medium, which are then transferred to fabric. This method utilizes special inks that bond well with a hot melt powder, creating vibrant and durable designs that can be applied to various materials.

How do I create designs for DTF transfers effectively?

To create effective designs for DTF transfers, it’s important to use professional graphic design software and set your artwork to CMYK color mode for optimal color accuracy. Ensure that your design is high resolution and mirror the image before printing for successful application.

What equipment do I need to start DTF transfer printing?

To start with DTF transfer printing, you will need a dedicated DTF printer, high-quality DTF film, pigmented inks, heat press, and hot melt powder. Investing in good equipment will significantly improve your printing results.

Can I use DTF transfers on various fabric types?

Yes, DTF transfers are versatile and can be used on a wide range of fabric types, including cotton, polyester, and blends. This flexibility makes DTF printing a popular choice for custom apparel.

What are some tips for mastering DTF transfers?

To master DTF transfers, choose quality materials like films and inks, regularly calibrate your printer, and experiment with different settings and fabrics. Following the right procedures will enhance the clarity and durability of your designs.

What recent developments can I expect in the world of DTF transfers?

Recent developments in DTF transfers include advancements in ink formulations for better durability, eco-friendly options for environmentally conscious consumers, and an expanding market appealing to both small businesses and hobbyists looking for efficient printing solutions.

| Step | Description | Key Tips |

|---|---|---|

| 1. Design Creation | Creating high-quality artwork for DTF transfers. | Use graphic design software, convert to CMYK, mirror designs. |

| 2. Printing the Design | Printing your artwork onto specialty DTF film. | Use a dedicated DTF printer, optimize settings, and mirror print. |

| 3. Powder Adhesion | Applying hot melt powder to the printed design. | Sprinkle powder while ink is wet, cure the powder. |

| 4. Heat Transfer | Transferring the design onto fabric using a heat press. | Preheat heat press, apply correct pressure and time. |

| 5. Peeling and Finishing | Finalizing the transfer process with careful peeling. | Allow cooling before peeling to avoid damage. |

Summary

DTF transfers have become a game changer in custom apparel printing, providing vibrant, high-quality designs with ease. This comprehensive guide outlines the essential steps—from crafting an impeccable design to executing a flawless transfer onto fabric—empowering you to harness this innovative technology. With the right materials and techniques, DTF transfers allow anyone, from small business owners to hobbyists, to create stunning custom apparel that stands out. As advancements continue in this field, the potential for your creativity is limitless, making now the perfect time to master the art of DTF transfers.