DTF transfers for tees have transformed DIY fashion by delivering vibrant color, durable adhesion, and a straightforward application process that empowers makers at any level to produce professional-looking garments from home, on demand, and with minimal waste. This method, often described as DTF transfer printing, bridges the gap between traditional screen printing and modern direct-to-garment options, offering full-color artwork, smooth gradients, and a softer hand feel that holds up through repeated washing when paired with the right materials and workflow. Whether you’re new to apparel hobbies or running a small operation, learning how to apply DTF transfers involves preparing your design, ensuring a clean surface, choosing compatible films and powders, and following a repeatable process that minimizes mistakes and maximizes color fidelity. DTF transfer designs can handle bold typography, photo-real imagery, and gradients, making it ideal for custom tees, merch drops, and limited runs; pairing them with a reliable heat press for DTF and precise temperature, pressure, and dwell-time controls yields consistent results across batches. In this concise introduction, you’ll see how this approach compares to DTG and vinyl, the essential steps involved, and practical care tips to extend the life of your prints, helping makers scale up with confidence and speed.

Alternative terms for this approach include direct-to-film deployment, film-to-fabric transfers, and print-on-film decoration, all pointing to the same idea: bold, durable graphics on textiles. From an LSI perspective, the discussion naturally pairs with concepts like bonding powder, heat press settings, color management, and garment workflows for small runs. Think of the process as a film-based print system, where artwork is prepared, films are heated with precise pressure, and the final image is bonded to fibers, framing the topic for readers interested in heat transfer methods. Using related keywords and synonyms helps search engines understand the topic’s breadth while keeping content approachable for hobbyists, designers, and entrepreneurs exploring tee designs and merch.

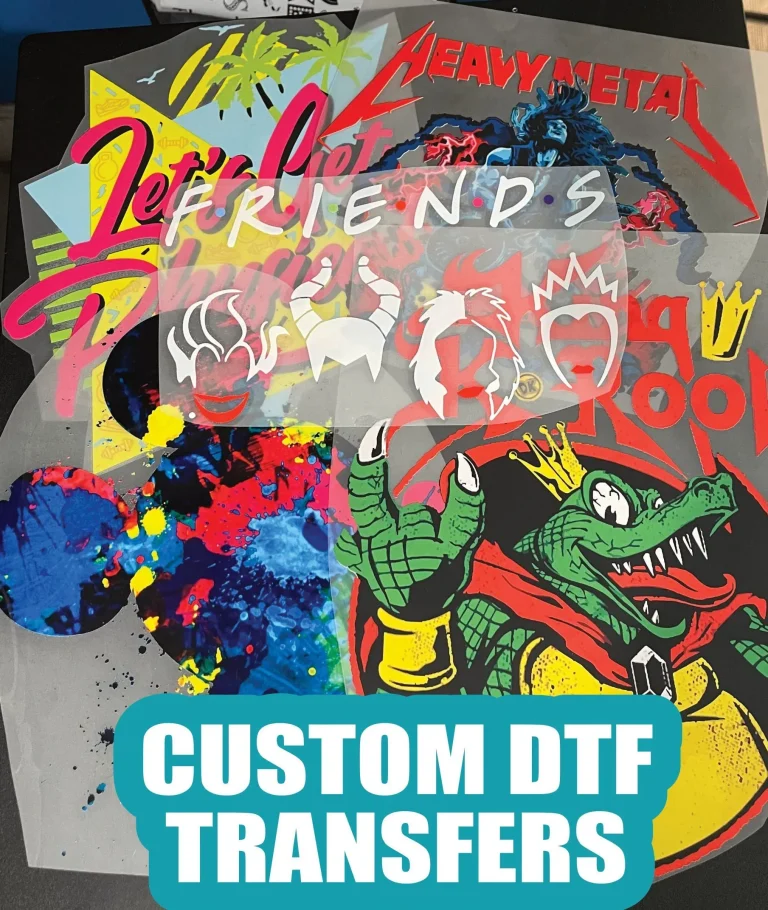

DTF transfers for tees: color, durability, and design versatility

DTF transfers for tees offer a compelling blend of vibrant color, soft handfeel, and reliable adhesion that makes them a favorite for DIY designers and small shops alike. By using water-based inks on a clear film and a bonding powder, this method delivers full-color designs with smooth gradients that rival traditional screen printing, while remaining forgiving on cotton blends and light fabrics. This quality makes DTF transfer printing a practical choice for hobbyists and entrepreneurs who need repeatable results without the high setup costs of other methods.

Design versatility is another key advantage. DTF transfer designs can include graphics, photographs, typography, and intricate gradients without layering per color as in vinyl or screen print workflows. To optimize results, prepare high-resolution artwork (vector art or PNG with a transparent background), ensure good edge definition, and mirror the image for correct orientation after transfer. When you combine thoughtful design with the right transfer film and transfer powder, you gain the ability to produce eye-catching tees with bold color and crisp detail.

How to apply DTF transfers: step-by-step with a heat press for DTF

Learning how to apply DTF transfers starts with a clean garment and a properly prepared workspace. Begin by pre-washing and pressing the tee to remove moisture and wrinkles. Print your design onto the DTF film using the correct ink set, then cure and bond the powder according to the supplier’s guidelines. This preparation ensures that the transfer adheres evenly to the fabric and minimizes edge lift during the pressing stage.

Next, trim and position the transfer carefully, centering or aligning any text as needed. Use a calibrated heat press for the pressing phase: set the recommended temperature, dwell time, and pressure, then apply firm, even heat across the design. After pressing, peel the carrier according to the specified method (hot or cold peel), and allow a brief post-press cure if advised. With attention to these steps—design prep, film handling, and precise heat application—you’ll achieve durable, vibrant results that demonstrate the strength and flexibility of DTF transfer printing.

To maintain quality over time, follow care guidelines such as washing tees inside out in cold or warm water and avoiding harsh detergents. This helps preserve the color depth and adhesion of your DTF transfers for tees, ensuring your designs remain sharp wash after wash. By leveraging the right heat press settings and accurate workflow, you can reproduce professional results even in small batches.

Frequently Asked Questions

How to apply DTF transfers for tees using a heat press for DTF to achieve durable, vibrant results?

Begin with a clean, pre-washed tee on a flat surface. Print your design onto DTF transfer film with the correct water-based inks and coating, then cure the bonding powder per the supplier’s guidelines. Position the transfer on the tee, cover with a protective sheet, and use a heat press for DTF at the temperature, time, and pressure recommended for your film. After pressing, peel the carrier according to hot or cold peel guidance, wait for a brief post-press cure if advised, and inspect for complete adhesion. Finally, wash the tee inside out and follow care instructions to preserve the DTF transfers for tees through regular wearing and washing.

What is DTF transfer printing for tees, and how should I handle DTF transfer designs to get the best results?

DTF transfer printing is a process that prints full-color designs onto a clear film, which is bonded to fabric with heat and pressure. For best results, design with high-contrast edges and use vector art or high-resolution PNGs with transparent backgrounds. Mirror the image before printing and ensure color management aligns with your ICC profile and film. After printing, apply the bonding powder, cure it, trim the transfer, and press with the recommended heat press settings and peeling method. Thoughtful DTF transfer designs combined with proper handling lead to vibrant, durable tees.

| Key Point | Details |

|---|---|

| What DTF transfers are | Direct-to-film process: design printed on a clear film with water-based inks, coated with bonding powder, cured, and transferred to fabric with heat and pressure for a vibrant, durable result. |

| Advantages for tees | Vivid color, smooth gradients, and good durability; forgiving on cotton blends; handles complex, multi-color designs; well-suited for small runs and quick turnaround. |

| When to choose DTF | Balances cost, quality, and ease compared with DTG, vinyl, and screen printing; ideal for custom orders or limited runs. |

| Tools and materials | Printer designed for water-based inks, DTF film, bonding powder, heat press; lint-free garments; thermometer; workspace; trimming tools. |

| Design considerations | Use high-contrast artwork; vector art or high-res PNGs with transparent background; mirror image before printing; ensure legibility of fine details. |

| Step-by-step process | Prepare garment; print on DTF film; apply bonding powder and cure; trim; position on tee; heat/press; peel carrier; post-press curing; inspect and care. |

| Troubleshooting | Adjust temperature, pressure, and dwell time; check ink density, printer calibration, and film quality; verify alignment and proper cutting; ensure proper post-press curing. |

| Care and durability | Wash inside-out; use cold/warm water; avoid bleach; tumble dry low or air dry; store away from direct sunlight to preserve color. |

| DTF vs other methods | Midpoint between DTG and screen printing; strong color reproduction, flexible application, and cost efficiency for small runs; softer hand than vinyl; durable adhesion. |

| Creative ideas and final thoughts | Expands design possibilities with logos, typography, gradients, photos, or hand-drawn art; practice and document settings to achieve consistent, scalable production. |