DTF Transfers for T-Shirt Business have revolutionized the custom apparel landscape, making it easier than ever for entrepreneurs to create vibrant and durable designs. Direct-to-Film (DTF) technology offers a unique advantage by providing a high-quality printing solution that outperforms traditional techniques like screen printing. As a T-shirt business owner, understanding the DTF transfer process is essential to achieving exceptional results and maximizing your market reach. With the right equipment and techniques, you can produce custom T-shirts that not only catch the eye but also withstand the test of time. This guide will walk you through the intricacies of DTF printing, ensuring you harness its full potential while appealing to your target audience.

The world of custom clothing, especially the T-shirt sector, is rapidly evolving with innovative techniques like DTF printing. Using Direct-to-Film technology allows businesses to create high-quality apparel with intricate designs and vibrant colors that capture customer attention. DTF transfers provide a cost-effective solution for those looking to produce customized T-shirts, enabling efficient production processes and versatile fabric choices. By investing in appropriate heat press machinery and understanding the DTF transfer process, entrepreneurs can significantly elevate their product offerings. This article will delve into the benefits and implementation of DTF technology to help aspiring T-shirt business owners thrive in a competitive market.

The Basics of DTF Printing for T-Shirt Businesses

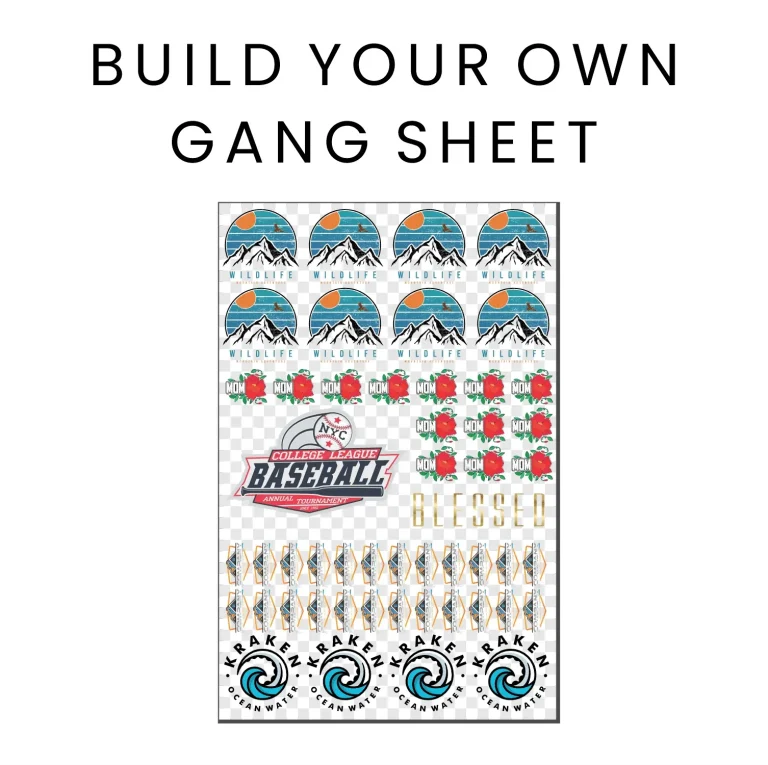

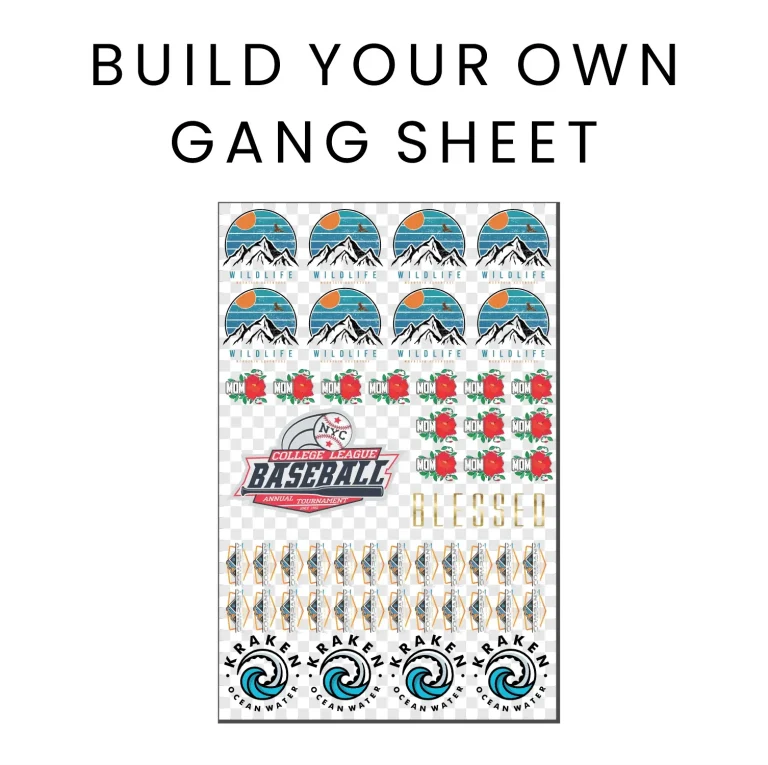

Understanding the basics of DTF printing is crucial for any T-shirt business looking to enter the custom apparel market. DTF, or Direct-to-Film, is a printing method where designs are printed onto a specialized film before being transferred to fabric. This method allows for vibrant, high-quality prints that can be applied to various materials, making it versatile for different T-shirt styles. Knowing how to navigate the DTF printing process can open doors to new business opportunities by catering to a wider audience.

Additionally, the efficiency of DTF printing makes it appealing for businesses that focus on custom work or limited runs. Unlike traditional printing methods, DTF allows for quick production times without sacrificing quality. By mastering DTF printing techniques, T-shirt businesses can elevate their offerings and respond to customer demands, making it an essential tool in today’s competitive market.

Frequently Asked Questions

What are the key benefits of using DTF transfers for my T-shirt business?

DTF transfers offer numerous benefits for T-shirt businesses, including exceptional quality and durability that withstands multiple washes, versatility to print on various fabrics beyond cotton, and cost-effective production for short runs, making them an ideal choice for custom T-shirt designs.

How does the DTF transfer process work for T-shirt printing?

The DTF transfer process involves printing a design onto a specialized film, which is then heat-pressed onto fabric using a heat press machine. This method ensures vibrant colors and high detail, allowing for intricate designs on a variety of materials.

What equipment do I need for successful DTF printing in my T-shirt business?

To implement DTF printing in your T-shirt business, you’ll need a reliable DTF printer, high-quality transfer films designed for DTF application, and a heat press machine to effectively transfer prints onto your T-shirts.

Can DTF transfers be used for customizing T-shirts?

Yes! DTF transfers are excellent for customizing T-shirts. They allow for personalization with unique designs, names, or graphics, catering to customer preferences and enhancing the appeal of your custom T-shirt offerings.

Is DTF printing more efficient than traditional T-shirt printing methods?

Yes, DTF printing is often more efficient than traditional methods like screen printing for custom T-shirts, particularly for small-batch orders. It simplifies the setup process and allows for quick and cost-effective production.

What types of fabrics can I use with DTF transfers for my T-shirt business?

DTF transfers are highly versatile and can be applied to a wide range of fabrics including cotton, polyester, blends, and more. This adaptability allows your T-shirt business to offer diverse product options to meet varying customer needs.

| Key Point | Details |

|---|---|

| Understanding DTF Transfers | DTF transfers involve printing designs onto a specialized film that is then heat-pressed onto fabrics, offering vibrant colors and intricate details. |

| Benefits of DTF Transfers | 1. Quality and durability, 2. Fabric versatility, 3. Efficient production. |

| Implementation Steps | 1. Invest in quality DTF printers and transfer films. 2. Utilize professional design software (Adobe Illustrator, CorelDRAW). 3. Conduct testing and regular quality control. |

| Marketing Strategies | 1. Identify and engage target audience. 2. Utilize social media to showcase designs. 3. Collaborate with influencers and local businesses. |

| Staying Ahead | 1. Eco-friendliness and sustainability. 2. Personalization and customization options for T-shirt designs. |

Summary

DTF Transfers for T-Shirt Business represent a groundbreaking advancement in custom apparel printing, enabling businesses to achieve high-quality prints that are durable and versatile across various fabrics. This innovative printing technology not only enhances the visual appeal of T-shirts but also allows small businesses to operate efficiently by facilitating quick production processes. As the demand for personalized and eco-friendly apparel rises, leveraging DTF transfers can significantly position your T-shirt business for success in a highly competitive market. By focusing on quality equipment, engaging marketing strategies, and staying updated with industry trends, businesses can thrive and attract a broader audience through the effective use of DTF technology.