DTF Transfers, or Direct-to-Film printing, represent a revolutionary advancement in the printing landscape, offering businesses innovative solutions for custom apparel printing. This cutting-edge technology allows for vibrant and intricate designs to be applied to a variety of fabrics, setting new standards in the industry. As the future of printing technology unfolds, DTF transfers are at the forefront, utilizing water-based inks that promote sustainable printing solutions. With efficiencies brought by automated printing processes, companies can now scale their operations without sacrificing quality or creativity. In this article, we’ll delve deeper into the mechanisms and advantages of DTF transfers, exploring how they are redefining the custom printing space into 2025 and beyond.

Direct-to-Film printing, often abbreviated as DTF, is rapidly becoming a sought-after method for high-definition graphics on textiles. Known for its versatility, this technique enables users to transfer eye-catching designs onto various substrates, paving the way for innovative approaches in custom apparel creation. As we navigate the evolving world of printing technology, the versatility and eco-friendliness of DTF printing are increasingly being recognized. This method not only streamlines production but also aligns with the growing demand for sustainable practices in the industry. With advancements in automated solutions seamlessly enhancing production times, businesses can efficiently meet the rising consumer expectations for personalized and responsibly produced items.

Understanding DTF Transfers: A Comprehensive Overview

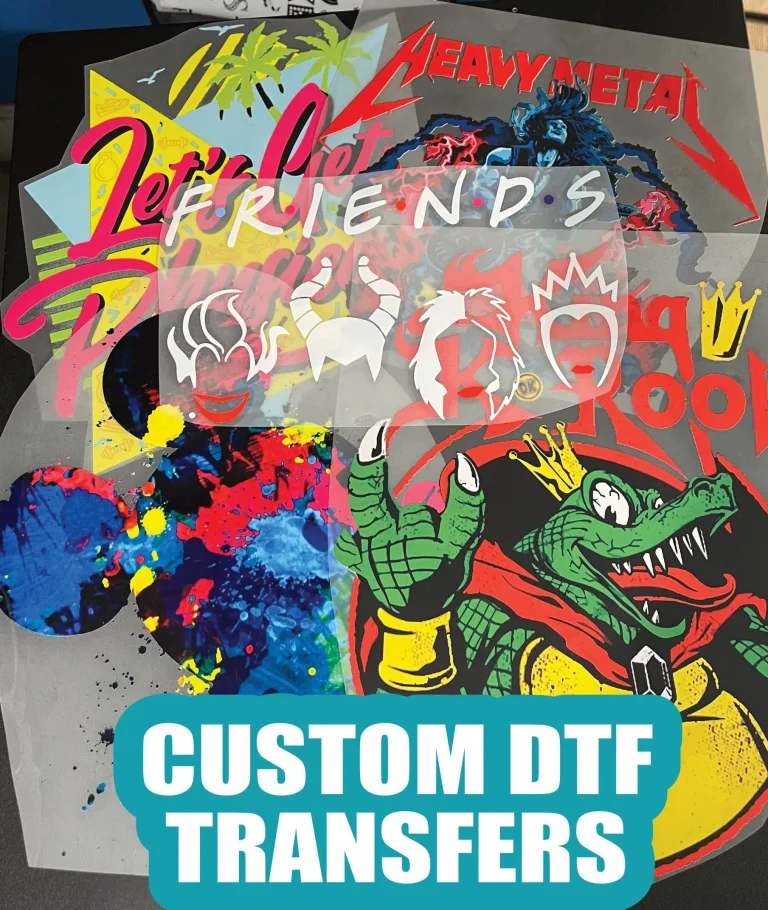

Direct-to-Film (DTF) transfers represent a revolutionary leap in the world of printing technology. This innovative method allows for vivid and detailed designs to be printed on various substrates, thereby expanding the horizons of custom apparel printing. Essentially, the DTF process involves printing designs on a specialized film, which is then heat-pressed onto the desired material. This technique offers a myriad of benefits, including increased durability and vibrancy of prints, making it a preferred choice for modern businesses and custom printing enthusiasts alike.

Furthermore, DTF transfers utilize water-based inks that are much more environmentally friendly than traditional solvent-based inks. This shift towards sustainable printing solutions not only resonates with eco-conscious consumers but also positions DTF printing as a frontrunner in environmentally responsible manufacturing. As the printing industry evolves, DTF technology stands out for its combination of high quality and sustainability, thus carving its niche in the marketplace.

Innovations Shaping the Future of DTF Printing

The future of DTF printing is brimming with exciting innovations that are set to transform the industry. For instance, advancements in color technology have led to the development of new nine-color printing systems, which significantly enhance color accuracy and vibrancy. This development allows for the reproduction of complex designs with breathtaking detail, appealing to creators and businesses aiming to push artistic boundaries. Enhanced color technology is essential for custom apparel printing, as it ensures that every detail of a design is represented faithfully, making products more appealing to consumers.

Aside from color improvements, the expanded material compatibility associated with DTF transfers is another trend that will drive future growth. DTF printing is no longer confined to textiles; it now accommodates materials such as leather, wood, and glass, allowing businesses to diversify their offerings in unique ways. This capability not only facilitates creativity but also opens up markets for businesses looking to cater to various customer needs, enhancing development opportunities across the board.

The Role of Automation in DTF Printing

Automation is becoming a cornerstone of DTF printing technology, marked by the adoption of sophisticated machinery designed to enhance production processes. For example, the introduction of models like the ARC 127 flatbed cutter has dramatically streamlined operations, reducing the time typically required for manual processes. Such technological integrations not only boost efficiency but also allow businesses to scale up production while maintaining print quality, thus meeting rising demand effectively.

The implications of automation extend beyond productivity; they also improve accuracy and reduce waste, aligning perfectly with the growing emphasis on sustainable printing solutions. As businesses increasingly turn towards automation in DTF printing, we can expect to see not only enhanced operational workflows but also a reduction in the environmental footprint typically associated with traditional printing methods. This alignment indicates that the future of DTF transfers is not only about speed but also about responsible manufacturing.

Sustainability Trends in DTF Printing

Sustainability in printing has moved from a niche concern to a mainstream expectation, and DTF printing is leading the charge with eco-friendly practices. The increasing use of biodegradable films and water-based inks is a testament to how DTF technology is adapting to meet consumer preferences for sustainable products. Companies that embrace these materials not only fulfill regulatory requirements but also appeal to the growing base of environmentally conscious customers seeking responsible purchasing options.

Furthermore, sustainable practices in DTF printing can enhance a brand’s image and consumer loyalty. As businesses adopt recyclable and biodegradable products, they position themselves as forward-thinking and responsible, resonating with consumers who prioritize environmental stewardship. This focus on sustainability could well become a determining factor in the competitive landscape of the printing industry as it moves toward 2025, benefiting both companies and consumers alike.

Custom Apparel Printing: The Competitive Edge of DTF Transfers

In the competitive landscape of custom apparel printing, DTF transfers offer a unique advantage that sets them apart from traditional printing methodologies. The technology facilitates intricate designs, including photographic images and complex artwork, to be recreated with exceptional clarity and brightness. These features not only enhance the aesthetic appeal of custom apparel but also cater to diverse consumer preferences, helping businesses stand out in a crowded marketplace.

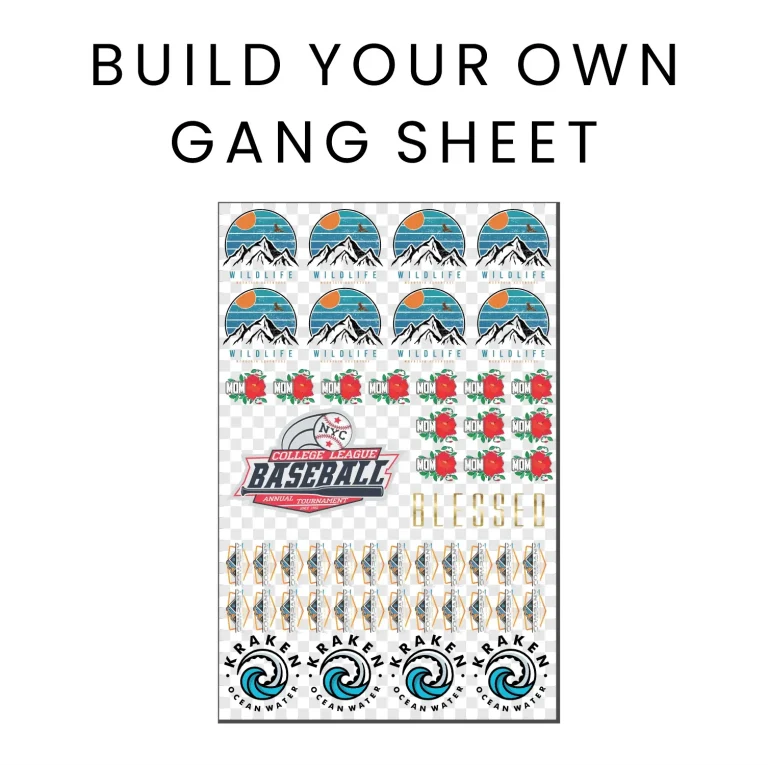

Moreover, the adaptability of DTF printing allows for smaller production runs without sacrificing quality, making it ideal for bespoke garment production. This flexibility appeals to both individual customers and businesses alike, as they can experiment with ideas and launch specialty collections without the burden of excessive inventory costs. DTF printing thus empowers brands to offer personalized products, enhancing customer satisfaction and driving loyalty through unique offerings.

Future Prospects: What’s Next for DTF Technology?

As we gaze toward the horizon of 2025, the printed media landscape is poised for transformative changes driven by DTF printing technology. Emerging trends suggest a potential hybridization of DTF with Direct-to-Garment (DTG) methods, which may enhance capabilities for high-volume production runs while allowing for material versatility. This combination could revolutionize how businesses approach print-on-demand services, tackling challenges associated with rapid fulfillment and diverse order sizes.

Additionally, ongoing research and development within DTF technology promise to introduce new equipment and eco-friendly methods of production aimed at minimizing environmental impact. Innovation is likely to focus on energy efficiency and minimizing waste through smarter printing processes. Brands that align with these emerging technologies will not only improve operational efficiencies but also reinforce their commitment to sustainable practices, making them attractive to today’s conscientious consumers.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel printing?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a special film which is then heat-pressed onto apparel. This method allows for vivid colors and detailed graphics on various fabrics, making it a popular choice for custom apparel printing.

How does DTF printing compare to traditional printing methods in terms of sustainability?

DTF printing is considered a more sustainable choice compared to traditional methods, as it primarily uses water-based inks and biodegradable films. This eco-friendly approach attracts consumers looking for sustainable printing solutions.

What innovations are shaping the future of DTF transfers in the printing industry?

Recent innovations in DTF transfers include enhanced color vibrancy through nine-color printing systems, expanded material compatibility for diverse substrates, and automation technologies that streamline production processes.

What types of materials can be used with DTF transfers?

DTF transfers are versatile and can be applied to a variety of materials, including cotton, polyester, leather, wood, and glass. This broad compatibility enables businesses to expand their product offerings in custom printing.

How do automated printing processes impact DTF transfers?

Automated printing processes significantly enhance DTF transfers by reducing manual labor and production times. Technologies like the ARC 127 flatbed cutter help businesses fulfill large orders efficiently while maintaining high quality.

Why is DTF printing considered the future of printing technology?

DTF printing is regarded as the future of printing technology due to its ability to produce high-quality, vibrant prints, sustainability benefits, versatility in material applications, and the incorporation of advanced automation to improve efficiency.

| Key Development | Description |

|---|---|

| Enhanced Color Vibrancy and Technology | Introduction of nine-color printing systems for richer, more accurate colors. |

| Expanded Material Compatibility | DTF printing can now be applied to leather, wood, glass, and more, expanding product offerings. |

| Automated Production Enhancements | Integration of automation tools to streamline operations and reduce production times. |

| Sustainability Trends | Growing use of biodegradable films and water-based inks to appeal to eco-conscious consumers. |

Summary

DTF Transfers are shaping the future of printing technology by introducing innovative advancements that cater to the evolving desires of consumers and businesses alike. As we approach 2025, these transfers are revolutionizing the printing landscape through enhanced color vibrancy, versatility in material application, and eco-friendly practices. The push for automation further ensures that printing processes become more efficient, allowing for the fulfillment of larger orders without compromising quality. Overall, DTF Transfers not only represent technical innovation but also align with consumer trends towards sustainability and unique customization.