DTF transfers, or Direct-to-Film transfers, are revolutionizing the landscape of custom apparel printing with their innovative approach and affordability. Unlike traditional printing methods such as screen printing and Direct-to-Garment (DTG) printing, DTF technology provides exceptional benefits for both small and large-scale operations. This cutting-edge technique enables vibrant and detailed designs to be applied effortlessly onto a variety of fabrics, ensuring a high-quality finish that customers crave. As businesses seek more efficient and effective printing solutions, DTF transfers emerge as a game-changer, offering flexibility and lower startup costs while maintaining superior output quality. Join us as we delve into the many advantages of DTF printing and how it stands tall against time-tested methods in the dynamic world of custom apparel.

When it comes to modern printing solutions for custom clothing, Direct-to-Film (DTF) technology stands out as a remarkable alternative to conventional techniques. Alternative terms like film transfer printing or direct film application describe the process that allows creators to apply designs directly onto fabrics with remarkable clarity and color vibrancy. This method not only enhances production speed but also offers businesses the ability to produce high-quality items, adapting easily to various textiles beyond what’s possible with other options like screen printing. As the demand for personalized apparel grows, exploring the benefits of such innovative printing methods becomes essential for those looking to thrive in the competitive customization market. Understanding these versatile approaches can help businesses meet shifting consumer preferences while maximizing creativity and quality.

Understanding DTF Transfers: A Revolutionary Printing Method

Direct-to-Film (DTF) transfers represent a groundbreaking shift in the world of custom apparel printing. This innovative technology enables high-quality designs to be printed onto transfer films, which are then applied to a variety of fabrics. Unlike traditional printing methods such as screen printing or Direct-to-Garment (DTG) printing, DTF offers a more flexible and efficient approach. The process involves printing designs on a special film followed by heat transfer, ensuring vibrant colors and intricate details that appeal to modern consumers.

With DTF transfers, businesses can easily create personalized items quickly, catering to the growing demand for custom apparel in today’s fast-paced market. This method is particularly advantageous for small to medium-sized operations, as it allows for shorter production runs without the hefty investments associated with traditional screen printing setups. By understanding the fundamentals of DTF transfers, companies can leverage this method to enhance their service offerings and attract a diverse clientele.

Advantages of DTF Transfers Over Traditional Printing Methods

One of the primary advantages of DTF transfers over traditional printing methods lies in their cost-effectiveness. For small-scale orders, DTF eliminates the need for extensive setup costs, such as creating screens for screen printing. This enables businesses to offer competitive pricing, especially when dealing with customized designs for clients who might only require a few pieces. In comparison, screen printing thrives on volume, often making it unfeasible for smaller orders.

Additionally, DTF transfers reduce material waste significantly. Traditional ink methods can become problematic due to oversaturation and misprints, leading to extra costs for businesses. DTF minimizes these issues by using a precision transfer application, which not only enhances profitability but also aligns with environmentally-conscious practices. This effectiveness makes DTF printing a strong contender in the evolving landscape of custom apparel.

The Efficiency of DTF Printing in Business Operations

DTF printing’s efficiency is another compelling reason to adopt this technology over conventional methods. The process is designed to be straightforward, allowing for quicker setups and faster turnarounds. Unlike screen printing, which requires meticulous manual work to prepare screens, DTF can be implemented with minimal downtime. This means that businesses can react swiftly to market demands and customer requests, something that’s increasingly vital in today’s competitive environment.

Moreover, the simplicity of DTF transfers streamlines production workflows. By minimizing labor-intensive preparations, employees can focus on high-value tasks, ultimately improving productivity and customer satisfaction. As more businesses recognize the importance of operational efficiency, DTF printing stands out as a pragmatic approach that complements modern manufacturing needs.

Quality Comparison: DTF Transfers vs. Traditional Methods

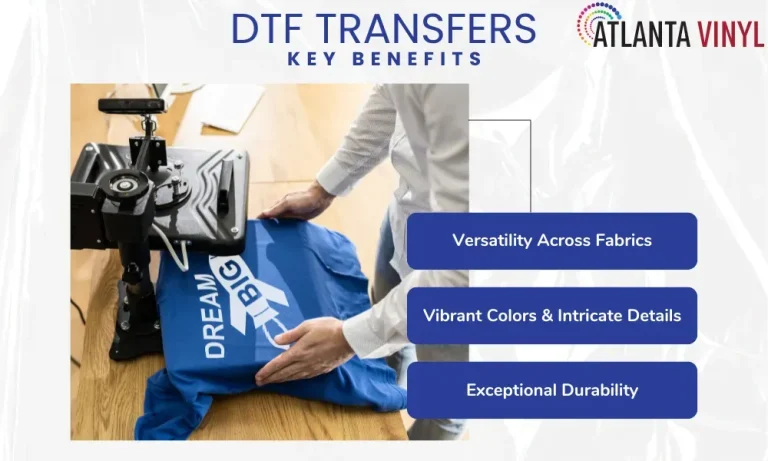

When assessing print quality between DTF transfers and traditional methods, DTF consistently outperforms in several key areas. DTF technology excels in producing vibrant colors and sharp details in designs, which is invaluable for brands aiming to create distinctive custom apparel. The finished product has a soft touch, which enhances the garment’s overall aesthetics and comfort—an aspect that many consumers prioritize when making purchases.

Traditional methods like screen printing produce high-quality results but can fall short in maintaining detail when multiple colors are involved. This limitation can affect the final appearance, making more complex designs less feasible. As trends shift towards individualized and intricate designs, DTF transfers become increasingly essential for businesses that wish to stay relevant and meet consumer expectations for style and quality.

Versatility in Fabric Choices with DTF Technology

The versatility of DTF printing allows it to accommodate a broader range of fabrics compared to traditional printing methods. While screen printing and DTG printing are often limited to cotton or specific blends, DTF transfers shine by performing superbly on both synthetic and natural fabrics. This adaptability grants businesses the ability to expand their product lines beyond typical apparel, allowing them to explore various items, from tote bags to sports jerseys.

Such flexibility opens new avenues for revenue generation, helping entrepreneurs tap into niche markets and cater to customers with diverse fabric preferences. The ability to offer printed products on multiple fabric types creates unique advantages, enabling businesses to stand apart from competitors who may be restricted by traditional printing limitations.

Current Market Trends Favoring DTF Printing

Analyzing current market trends reveals a significant shift towards the adoption of DTF printing within the custom apparel landscape. As consumer preferences evolve towards quick-turnarounds and personalized items, businesses are recognizing the advantages that DTF technology offers. Recent studies indicate an increasing number of companies are integrating DTF into their production processes to meet market demands effectively.

Industry analysts predict that the DTF printing market will continue to expand through 2030, fueled by innovations and the need for customized solutions. As more brands embrace DTF transfers, the printing landscape is poised for a transformation that could reshape how custom apparel is produced and delivered, positioning DTF technology at the forefront of the industry.

Frequently Asked Questions

What are the advantages of DTF transfers compared to traditional printing methods?

DTF transfers offer several advantages over traditional printing methods such as screen printing and Direct-to-Garment (DTG) printing. Key benefits include cost-effectiveness for smaller orders, faster setup and reduced downtime, vibrant color output and detail, and versatility across various fabric types, including synthetics. These features make DTF printing increasingly popular in the custom apparel industry.

How does DTF printing contribute to cost-effectiveness in custom apparel production?

DTF printing boasts cost-effectiveness for custom apparel production by minimizing setup expenses, particularly for small to medium-sized orders. Unlike traditional methods like screen printing that require significant initial investments, DTF allows businesses to avoid heavy costs and achieve savings through flexible production runs, making it an ideal choice for startups and smaller operations.

Can DTF transfers provide better quality than traditional screen printing or DTG methods?

Yes, DTF transfers often provide superior print quality compared to traditional screen printing and Direct-to-Garment (DTG) methods. They produce vibrant colors and fine details, along with a softer finish that improves the garment’s wearable quality. While traditional methods can achieve high quality as well, DTF ensures consistent performance across varying designs and fabric types.

What types of fabrics can be printed using DTF transfers compared to traditional printing methods?

DTF transfers are highly versatile and can be applied to a wide range of fabrics, including synthetics, unlike traditional methods like DTG that predominantly work well with cotton. This versatility allows businesses to expand their custom apparel offerings to include items such as tote bags, hats, and uniforms, giving them a competitive edge in the market.

What current market trends are influencing the adoption of DTF printing in the custom apparel industry?

Current market trends indicate a significant shift toward DTF printing technology in custom apparel due to its efficiency, quality, and growing consumer demand for faster turnarounds on high-quality products. Analysts suggest that the DTF printing market is set to expand through 2030, driven by innovation and evolving customer preferences, marking DTF as a game-changer in the industry.

Is DTF printing easier to use than traditional methods like screen printing?

Yes, DTF printing is generally easier to use compared to traditional methods like screen printing. The DTF process typically involves fewer intricate setups and manual labor associated with creating screens, allowing for quicker operations and reduced downtime. This ease of use enables businesses to respond swiftly to customer demands, enhancing overall efficiency.

| Key Point | DTF Transfers | Traditional Printing Methods |

|---|---|---|

| Cost-Effectiveness | Lower startup costs, ideal for small to medium-sized orders. | Higher initial investment required, more economical at larger volumes. |

| Ease of Use | Faster setup and streamlined operations, reducing downtime. | More complex setup involving manual processes and longer preparation time. |

| Quality of Output | Produces vibrant colors and soft finishes, high detail. | Can offer high-quality prints but may lack consistency in detail. |

| Versatility | Can print on a variety of materials, not limited to cotton. | Limited to specific fabric types, such as cotton. |

| Market Trends | Rapid adoption and projected growth due to innovations & demand for quality. | Stable, but may face competitive pressure from DTF technology. |

Summary

DTF Transfers represent a significant advancement in the custom apparel and printing industry, distinguished by their cost-effectiveness, ease of use, and exceptional output quality. As businesses adapt to the increasing demand for customized and high-quality products, DTF technology is becoming an essential solution for meeting consumer expectations without heavy financial burdens. The ability of DTF to work across various fabrics allows companies to cater to a broader market, thus enhancing their competitive edge. It is clear that understanding and utilizing DTF Transfers can empower entrepreneurs to thrive in the evolving landscape of custom printing.