DTF transfers have transformed how designers bring vibrant, durable imagery to fabrics, and this guide focuses on DTF transfer techniques that simplify the workflow. From setup to finish, understanding the DTF printing process and following a practical DTF printing guide helps you achieve consistent results. Practical tips, including mindful DTF printer setup, help ensure sharp details across a range of fabrics. This introduction previews five essential techniques you can apply right away to improve texture, color, and durability. Whether you’re new to DTF printing or aiming to refine your production, these ideas will help you deliver standout transfers with reliability.

Direct-to-Film printing can also be described as a film-based transfer approach that pairs a printed design with an adhesive layer to apply vivid graphics to textiles. In practice, this process hinges on precise image preparation, powdering, curing, and heat-press execution—terms that echo the methods outlined earlier but framed with alternative terminology. When you decorate garments, think in terms of transfer film, adhesive-coated sheets, and color-ready prints compatible with cotton, blends, and synthetics. Adopting an LSI approach means grouping related ideas like color management, substrate compatibility, and workflow consistency under different labels to boost discoverability. Whether you call it film-to-fabric printing, adhesive transfer, or a modern dye-sub-inspired technique, the core principles remain: prepare designs carefully, calibrate equipment, and verify results with test runs.

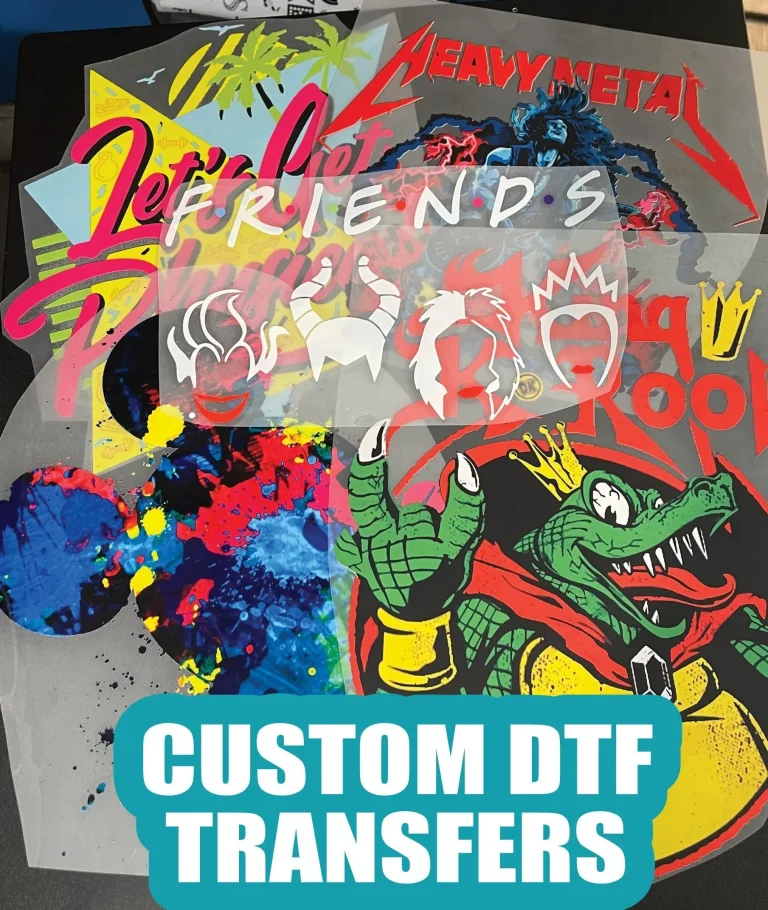

DTF transfers: Mastering five core techniques for vibrant, durable prints

DTF transfers require a disciplined approach that spans design, preparation, powdering, curing, and heat-press execution. Framing your work around the five core DTF transfer techniques ensures you achieve sharp details, bright colors, and strong adhesion across a range of fabrics. This approach aligns with a practical DTF printing guide, providing actionable steps you can implement today to improve consistency and longevity of each transfer.

A key part of mastering these techniques is understanding how the workflow connects to your equipment and setup. From substrate selection and white ink planning to powder distribution and post-press handling, every choice affects final results. Integrating considerations from a solid DTF printer setup and adhering to best practices in the DTF printing process will help you reduce variability, optimize color fidelity, and extend the life of your transfers.

DTF printing guide: optimizing your process from design to finish

This subheading focuses on the print stage and how careful control over design, color management, and press readiness translates into durable transfers. By following the principles outlined in a thorough DTF printing guide, designers can tune vector versus raster workflows, establish reliable white-layer density, and calibrate printers for accurate skin tones, greens, and blues. Emphasizing a consistent DTF printing process and using test swatches helps lock in color accuracy before production runs.

Beyond the printer itself, attention to maintenance, RIP settings, and layering order supports repeatable results. Regularly cleaning print heads, verifying nozzle health, and using printer profiles tailored to film and fabric minimize edge blur and color shifts. As you apply DTF transfer tips during print preparation and link them to your DTF printer setup, you create a robust pipeline that yields crisp edges and vibrant, durable outputs.

Frequently Asked Questions

What are the essential DTF transfer techniques and how does the DTF printing guide help improve your DTF transfers?

Core DTF transfer techniques include design preparation, powdering and curing, print quality control, precise heat-press execution, and post-transfer care. A solid DTF printing guide provides a repeatable workflow, emphasizing color management, white ink underbase considerations, substrate prep, and step-by-step procedures to improve adhesion, color accuracy, and durability across fabrics.

What steps in the DTF printer setup and DTF printing process ensure durable, vibrant transfers across fabrics?

Start with a reliable DTF printer setup—clean heads, proper alignment, and correct film settings—and follow a consistent DTF printing process that uses a dense white base when needed, accurate color profiles, and proper layering order. Finish with careful powdering, curing, and heat-press control to maximize adhesion, color brightness, and long-term durability on a range of fabrics.

| Technique | Focus / Summary | Key Points |

|---|---|---|

| Technique 1: Prepare designs for flawless DTF transfers | Design readiness for successful DTF transfers | – Clean artwork; optimize resolution; color separation; substrate compatibility; white ink planning. – Use vector art when possible; if raster, aim for 300 dpi final size. – Manage color with calibrated workflows and ICC profiles. – Plan white base density and alignment; prep substrate (clean, dry). – Ensure white layers are considered like color layers. |

| Technique 2: Master the powdering and curing process | Durable adhesion through even powdering and proper curing | – Powder evenly; too little causes poor adhesion, too much dulls colors. – Perform hot-tack test to verify powder adherence. – Use controlled curing temps, timing, and airflow. – Allow cooled film to set before handling. |

| Technique 3: Optimize print quality and color fidelity (DTF printing guide) | Calibrated printing for crisp details and accurate colors | – Regular printer maintenance (heads, nozzles, alignment). – RIP/color profiles tuned to film/textile. – Print white layer first when required; ensure density for dark garments. – Create test swatches; verify under different lighting. – Balance resolution and ink density with processing speed. |

| Technique 4: Set heat press parameters and timing precisely (DTF transfer techniques) | Controlled heat, pressure, and timing for durable transfers | – Follow manufacturer guidelines for temp/pressure. – Use consistent dwell time; adjust for fabric type. – Choose hot or cold peel per adhesive/film. – Adapt for cotton, blends, synthetics; post-press checks to ensure set. – Allow post-press cooling to improve bond. |

| Technique 5: Post-transfer finishing and care (DTF printing process durability) | Care and finishing to preserve vibrancy and durability | – Cool on a flat surface before packaging. – Wash inside-out in cold water; mild detergent; avoid harsh chemicals/high heat. – Optional post-press cure for extra durability per adhesive guidelines. – Store away from sunlight and humidity. – Troubleshoot by reviewing design prep, powdering, curing, heat-press settings. |

Summary

Conclusion: Mastering DTF transfers comes down to disciplined preparation, precise powdering and curing, meticulous print quality control, careful heat-press execution, and thoughtful post-transfer care. By embracing these five essential techniques and integrating them into a consistent workflow, you’ll see sharper details, brighter colors, and longer-lasting results across a wide range of fabrics. Whether you’re producing small runs or scaling up to larger orders, a solid understanding of DTF transfer techniques will elevate your work and keep customers coming back for more.