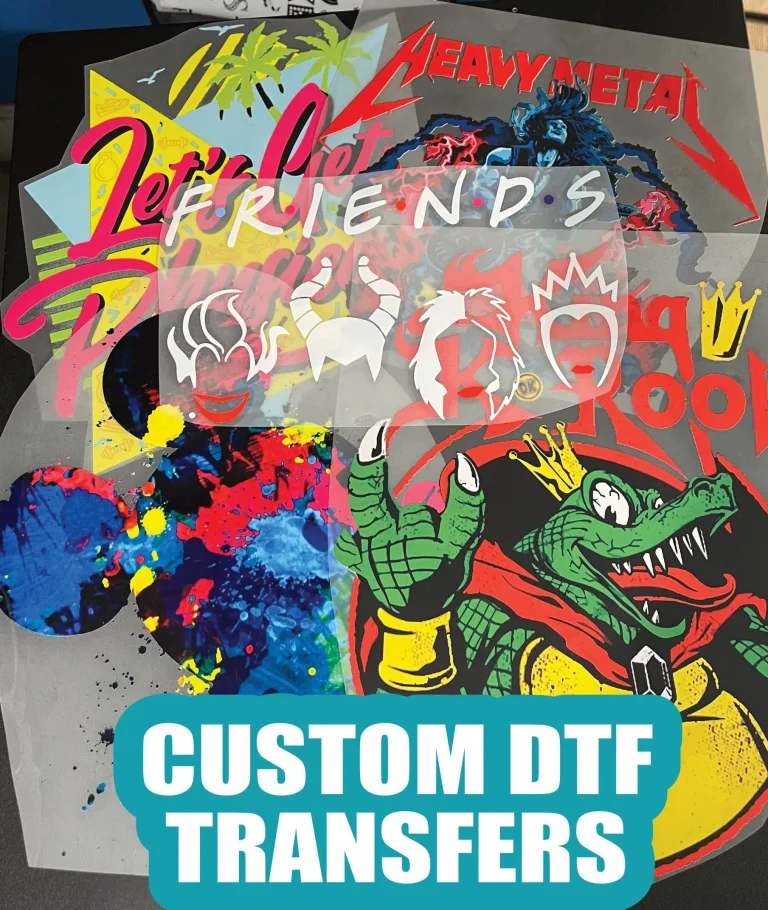

DTF Supplies are essential for anyone looking to harness the full potential of Direct to Film (DTF) printing, which has revolutionized the textile industry with its capacity for producing vibrant, high-quality designs. This modern printing method utilizes specialized DTF transfer film to capture intricate graphics, while DTF inks provide the depth and richness needed for long-lasting prints. Additionally, DTF adhesive powder plays a critical role in ensuring that these designs adhere flawlessly to fabrics during the transfer process. By choosing quality DTF supplies, businesses can enhance their production efficiency and deliver products that satisfy customers’ expectations for durability and brilliance. In this overview, we will explore the significance of each component and how they contribute to spectacular print results.

In the realm of fabric decoration, Direct to Film (DTF) printing stands out as a cutting-edge process that modernizes the way designs are applied to materials. This method, characterized by its use of film as a medium for transferring artwork, relies on a selection of critical materials, including transfer films designed specifically for this technique, unique inks that ensure rich color saturation, and adhesive powders that facilitate enduring prints. As more businesses embrace this innovative approach, understanding the tools and supplies that underpin successful DTF operations becomes increasingly important. Whether referred to as film-based transfer printing or utilizing specific DTF components, mastering these elements can lead to impressive and reliable results in the fast-evolving world of textile printing.

Understanding DTF Transfer Film

DTF transfer film is a pivotal element in the Direct to Film printing process, serving as the canvas for vibrant and intricate designs. This specialized film is coated to allow for exceptional ink adhesion and vibrant color reproduction, which are essential for a successful transfer. Different types of films can yield varying results, but high-quality transfer film ensures clarity and detail, making your prints more appealing to the eye.

Moreover, the choice of DTF transfer film can significantly affect the durability of the final print on textiles. Films that offer superior coating technology will provide better ink absorption and retention, ensuring that your designs withstand multiple washes without fading or peeling. This not only enhances customer satisfaction but also contributes to a business’s reputation for quality.

The Role of DTF Inks in Quality Printing

DTF inks are specifically formulated to offer rich colors and high durability when printed on transfer films. Unlike standard inks that might fade over time, DTF inks are designed to resist fading and flaking, ensuring your designs maintain their vibrancy even after repeated laundering. Utilizing top-shelf DTF inks can provide you with impressive color saturation and high-quality prints that can command higher price points.

In addition, environmental considerations are becoming increasingly important in the printing industry. Many DTF inks are water-based and eco-friendly, aligning with growing consumer demand for sustainable practices. By choosing inks that are not only efficient but also environmentally responsible, businesses can cater to a more conscious consumer base while also improving their brand image.

Selecting the Right Adhesive Powder for DTF Success

The right adhesive powder plays a crucial role in ensuring that prints adhere properly to garments during the DTF process. This powder helps create a strong bond between the ink and the fabric, which is vital for producing a long-lasting product. Without quality adhesive powder, you may encounter issues like print peeling or cracking, which could ultimately harm your business’s reputation.

Moreover, the method of applying the adhesive powder needs to be consistent; applying it correctly ensures even coverage, which supports uniform adhesion. Investing in high-quality adhesive guarantees that your prints perform well on a range of fabric types, giving you the versatility needed to meet various client demands.

Choosing the Right Heat Press for DTF Printing

A quality heat press is essential in the DTF printing process as it directly influences the transfer of images from film to garment. The right machine applies the precise temperature and pressure necessary for a successful transfer, guaranteeing that designs do not fade or lift after washing. Choosing a heat press with adjustable settings allows for more control, enabling you to produce consistent results.

Additionally, investing in a reliable heat press can enhance overall production efficiency. Lack of equipment failures and a shortened transfer time can lead to less material waste and higher profits. When selecting a heat press, consider features such as temperature accuracy and the size of the platen to accommodate various print sizes, ensuring versatility for future projects.

The Significance of Quality DTF Supplies

Using high-quality supplies is paramount for anyone serious about DTF printing, as it directly correlates to the quality of the final product. Premium materials like DTF transfer film, inks, and adhesive powders significantly enhance print clarity and durability. Customers expect their garments to remain vivid and intact after multiple washes, and utilizing top-tier supplies helps meet these expectations.

Moreover, the improved efficiency that comes with quality supplies can streamline the production process. With fewer errors and better adhesion, businesses can save time and reduce costs associated with reprints and material wastage. Ultimately, investing in superior DTF supplies can lead to higher customer satisfaction and loyalty, essential factors in a competitive market.

The Future Trends in DTF Printing

As DTF printing continues to evolve, several trends are emerging that may shape the future of this industry. Innovations in technology are making DTF printers more user-friendly and efficient, enabling faster production speeds and enhanced quality features. This advancement creates opportunities for businesses to scale their production without compromising the integrity of their designs.

Additionally, the rising demand for sustainable practices in textiles is driving developments in eco-friendly DTF supplies. More manufacturers are focusing on creating water-based inks and recyclable transfer films that reduce environmental impact. Adapting to these trends not only caters to a growing consumer base that values sustainability but also positions companies at the forefront of responsible printing practices.

Frequently Asked Questions

What are DTF supplies and why are they important for DTF printing?

DTF supplies refer to the essential materials used in Direct to Film (DTF) printing, including DTF transfer film, DTF inks, adhesive powder, and heat presses. These supplies are crucial as they directly influence the quality, durability, and overall success of the printing process. High-quality DTF supplies ensure vibrant colors, effective adhesion, and long-lasting prints on garments, making them vital for any printing business.

How does DTF transfer film impact the quality of prints?

DTF transfer film plays a critical role in the Direct to Film printing process. It is specially coated to enhance color vibrancy and detail. Using superior quality DTF transfer film ensures better ink transfer, resulting in clearer and more vibrant prints. A good transfer film is essential for achieving the high-quality results that customers expect from DTF printing.

What types of DTF inks should I use for the best results?

The best DTF inks are water-based inks specifically designed for DTF printing. These inks produce rich, vivid colors that resist fading and flaking, making them ideal for high-quality prints. Using quality DTF inks is essential for ensuring that designs maintain their appearance after multiple washes and contribute to the overall durability of finished products.

Why is adhesive powder necessary for DTF printing?

Adhesive powder is crucial in the DTF printing process as it helps the printed ink adhere effectively to the fabric during the transfer process. Applying high-quality DTF adhesive powder ensures a strong bond between the print and the garment, enhancing the durability of the design. Without proper adhesive, prints may peel off or wear out quickly, leading to customer dissatisfaction.

What is the role of a heat press in DTF printing?

A heat press is an essential tool in DTF printing, used to apply the necessary heat and pressure to transfer the image from the DTF transfer film to the fabric. The right heat press can significantly impact the transfer quality, ensuring that the design is properly adhered to the garment. Following manufacturer guidelines for temperature and pressure is critical for achieving the best results.

How do I choose the best DTF supplies for my printing business?

To choose the best DTF supplies for your printing business, look for reputable suppliers that offer high-quality DTF transfer film, eco-friendly DTF inks, and reliable adhesive powders. Important factors to consider include product reviews, compatibility with your equipment, and the specific demands of your printing projects. Investing in quality materials is crucial for producing vibrant, durable prints and enhancing customer satisfaction.

| Supply | Description |

|---|---|

| DTF Transfer Film | Specially coated film that enhances vibrancy and clarity of prints. |

| DTF Inks | Rich, vivid water-based inks designed for durability and eco-friendliness. |

| Adhesive Powder | Applied to ensure ink adheres properly to fabric, enhancing durability. |

| Heat Press | Applies heat and pressure to transfer designs from film to garments. |

Summary

DTF Supplies are essential for anyone entering the realm of textile printing. This innovative process, which allows for high-quality prints on various fabrics, relies heavily on key supplies like transfer films, inks, adhesive powders, and heat presses. By investing in superior quality materials, businesses not only enhance the vibrancy and durability of their designs but also ensure a smoother production process with better overall results. As the demand for DTF printing continues to grow, the importance of quality supplies cannot be overstated for achieving success in this competitive market.