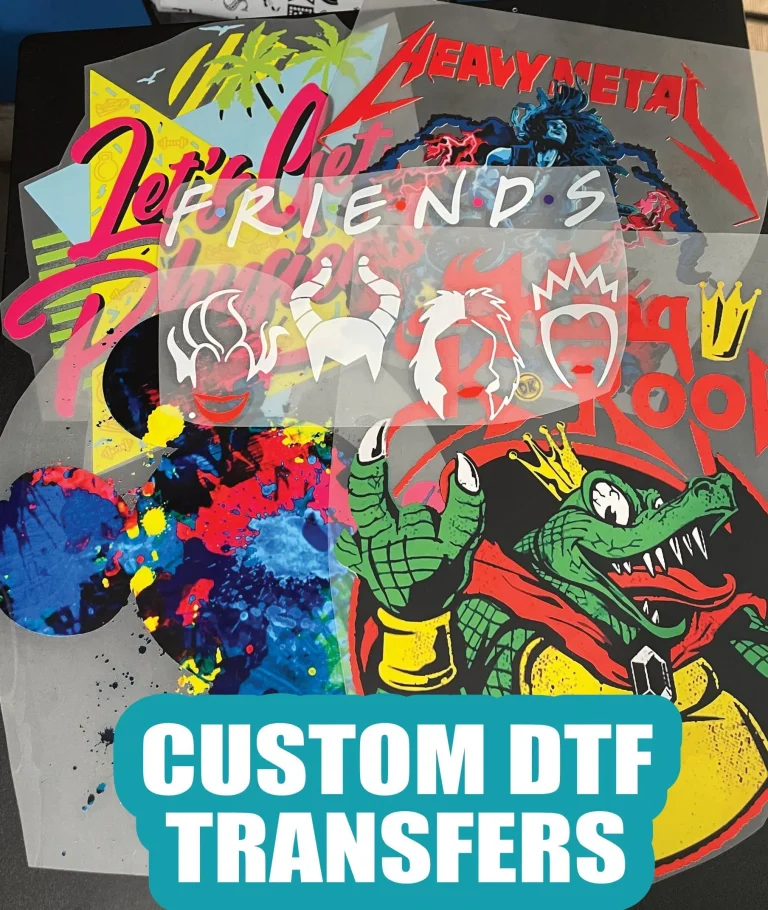

DTF supplies are essential for anyone looking to elevate their custom apparel and textile printing game. This innovative technology, known as Direct-to-Film (DTF) printing, utilizes high-quality DTF inks and transfer films to create vibrant designs on a variety of fabrics. By incorporating DTF adhesive powder and reliable heat press machines into your workflow, you can ensure that your prints not only look stunning but also withstand the test of time. In this guide, we will delve into the must-have supplies that can help you maximize print quality and maintain customer satisfaction. Whether you’re a seasoned print shop owner or just starting, understanding the right DTF supplies is crucial for achieving remarkable results.

When discussing essential materials for high-quality textile printing, the terminology often varies, but the core concepts remain the same. The tools and products known as DTF supplies include key elements like Direct-to-Film inks, transfer coatings, bonding powders, and industrial heat press machines. These components play a pivotal role in the efficiency of the printing process, whether referred to as film transfers or bonding agents for textile prints. By exploring the landscape of these indispensable materials, one can uncover the secrets to producing exceptional prints that resonate with customers. In this article, we will unveil various aspects of these supplies while ensuring that your approach to apparel printing is informed and effective.

The Importance of High-Quality DTF Inks

High-quality DTF inks are the lifeblood of any successful Direct-to-Film (DTF) printing operation. These inks are formulated to provide vibrant colors and ensure that the prints adhere effectively to a variety of fabrics. When selecting DTF inks, consider opting for eco-solvent options, which are environmentally friendly while delivering superior color vibrancy and durability. It’s crucial to select inks that are compatible with the specific profiles of your printer to ensure optimal color reproduction and thread detailing, thus enhancing the overall print quality.

Moreover, the performance of DTF inks directly influences the longevity of your prints. High-quality inks are less likely to fade or wash out over time compared to lower-grade alternatives, making them a wise investment for your print shop. Crafting bold and detailed designs becomes effortless when using inks that effectively bond with both the film and the fabric, giving you the freedom to experiment with intense colors and intricate patterns that satisfy your customer’s expectations.

Exploring the Types of Transfer Films

Transfer films are essential in DTF printing, acting as the medium that carries the ink from printer to fabric. Selecting the right transfer films is critical, as their quality and compatibility can make a significant difference in the final output. Look for films with high-quality coatings to enhance ink absorption. This characteristic not only improves the vibrancy of the colors but also ensures that the printed designs adhere properly to various types of fabrics after the heat transfer process.

Additionally, the compatibility of transfer films with your chosen DTF inks cannot be overlooked. Using films that match your ink specifications can lead to stunning results, as the ink bed will be properly set and won’t smudge or fade during or after application. By prioritizing high-grade transfer films, you can significantly elevate the quality of your prints and expand the range of materials you are able to print on, accommodating both cotton and synthetic blends.

Choosing the Right DTF Adhesive Powder

DTF adhesive powder plays a crucial role in ensuring that your prints maintain their integrity during and after the heat application process. When selecting adhesive powder, it is essential to opt for high-quality products specifically designed for DTF applications. A quality adhesive powder should dissolve uniformly and adhere well, ensuring that your designs last even after repeated washes, thereby improving customer satisfaction and repeat business.

Moreover, the type of fabric you are printing on also matters when choosing adhesive powder. Different fabrics may require different types of adhesive to achieve the best bond. By understanding the characteristics of your fabrics and their compatibility with specific powders, you can enhance the overall quality and durability of your prints. Experimenting with various powders can also yield insights into which combinations provide the best results for your unique printing needs.

Investing in Reliable Heat Press Machines

A dependable heat press machine is an indispensable tool in DTF printing, and investing in one can greatly affect the success of your printing operations. A quality heat press should offer consistent temperature control and even heat distribution to ensure that the adhesive powder sets properly and that the design transfers seamlessly. Without precise temperature regulation, the adhesion may suffer, leading to poor quality prints that do not meet customer standards.

Furthermore, modern heat press machines come equipped with programmable features allowing you to set time and temperature presets tailored to different types of fabrics and adhesive powders. This automation not only streamlines the production process but also minimizes the risk of human error, leading to more consistent and high-quality prints. By investing in such advanced equipment, you position your print shop for success and build a reputation for reliability and excellence.

Enhancing Print Quality with Protective Pre-Treatment Solutions

Utilizing protective pre-treatment solutions is a game changer for achieving superior print quality, especially when working with darker fabrics. These treatments enhance ink absorption, allowing the ink to penetrate deeper into the fabric fibers rather than simply resting on the surface. This deeper absorption not only improves color vibrancy but also increases the durability of the print, ensuring that it withstands multiple washes without fading or cracking.

Moreover, by applying effective pre-treatment, you create a better foundation for the DTF transfer, enhancing the overall finish of your designs. This added step may require an initial investment in both materials and equipment, but the payoff comes in the form of satisfied customers who appreciate the quality and longevity of their custom apparel. Pre-treating fabrics is an essential step for any print shop aiming to deliver consistently high-quality results.

Emerging Trends in DTF Supplies for Competitive Edge

In the fast-evolving world of DTF printing, keeping abreast of emerging trends can provide a competitive advantage. One such trend is the increased demand for sustainable and eco-friendly supplies. As consumers become more conscientious about environmental impact, suppliers are responding by offering inks and materials that are free from harmful chemicals and toxins. Adopting these sustainable practices not only attracts a broader customer base but also enhances your brand image as an eco-friendly business.

Additionally, the versatility in fabric compatibility is another growing trend impacting the DTF supplies market. Suppliers are innovating materials and inks that can be effectively used on a wider array of fabrics, including blends and unique textiles. This flexibility allows print shops to expand their range of offerings, catering to diverse clientele and capturing new market segments. By staying updated on these trends, print shop owners can make strategic decisions that align with consumer preferences, ultimately driving growth and success.

Frequently Asked Questions

What are the essential DTF supplies needed for optimal print quality?

To achieve optimal print quality in Direct-to-Film (DTF) printing, essential supplies include high-quality DTF inks, transfer films with proper coating, adhesive powders, and reliable heat press machines. These components work together to ensure vibrant colors and durable designs.

How do high-quality DTF inks impact the printing process?

High-quality DTF inks are crucial as they provide vibrant colors, ensure better adherence to fabrics, and offer wash resistance. Selecting eco-solvent inks can enhance print quality while being environmentally friendly, making them ideal for DTF printing.

What role do DTF transfer films play in the printing process?

DTF transfer films are vital as they absorb the ink and facilitate its transfer to fabric. A quality-coated film enhances ink adhesion and impacts the final print’s vibrancy. Compatibility with the DTF inks you use is also important for best results.

Why is adhesive powder necessary for DTF printing?

Adhesive powder acts as a bonding agent, ensuring that the printed design adheres well to the fabric after heat application. Choosing high-quality adhesive powders guarantees they dissolve evenly and maintain the integrity of the design through multiple washes.

How does a heat press machine affect DTF printing quality?

A heat press machine provides the necessary temperature and pressure to transfer designs effectively. Consistent temperature control is vital for activating the adhesive powder, while programmable settings help tailor applications to various fabric types.

What trends are emerging in DTF supplies that print shops should consider?

Emerging trends in DTF supplies include a focus on sustainability with eco-friendly inks, advancements in materials that increase fabric compatibility, and continuous innovations in DTF printing technology. Staying updated on these trends can enhance service offerings and customer appeal.

| Key Points | Details |

|---|---|

| Understanding DTF Printing | Versatile printing technique for vibrant designs on various fabrics. |

| High-Quality DTF Inks | Eco-solvent inks for vibrant colors and durability. |

| Transfer Films | High-quality coating enhances ink absorption for better prints. |

| Adhesive Powder | Ensures design adheres to fabric post-heat application. |

| Heat Press Machines | Consistent temperature control for even heat distribution. |

| Protective Pre-Treatment Solutions | Improves ink absorption and durability of prints. |

| Emerging Trends | Focus on sustainability and versatility in fabric compatibility. |

Summary

DTF supplies play a crucial role in achieving exceptional print quality in the custom apparel industry. Investing in high-quality inks, transfer films, adhesive powders, heat press machines, and protective pre-treatment solutions helps ensure each print is vibrant and durable. Additionally, staying updated with trends, including sustainability and materials compatibility, will help print shops not only meet but exceed customer expectations. Embracing these best practices enables businesses to maintain a competitive edge while delivering superior products.