DTF supplies have surged in popularity as a flexible, cost-effective option for garment decoration. If you’re weighing your options for your print shop or small business, understanding how DTF printing works and how direct-to-film supplies compare with other methods—such as DTG vs DTF—can save you time, money, and frustration. This introductory guide highlights the role of the DTF transfer film and explains why selecting the right DTF printing supplies, powders, and heat presses matters for consistent results. You’ll see how film-based transfers stack up in a printing methods comparison for color vibrancy, durability, and hand feel across fabrics. Optimizing your choice of DTF supplies can shorten setup, boost throughput, and keep projects on budget.

In other terms, the film-based transfer workflow for clothing decoration centers on printing onto a specialized translucent sheet and then bonding the design to fabric. This approach leverages a color-rich film, adhesive powders, and heat application to deliver durable, washable images on a wide range of textiles. From a search-engine perspective, you’ll want to explore terms like garment printing on film, color transfer film, and affordable color transfer solutions when researching products. Understanding the supply chain—inks, films, powders, and compatible presses—helps clarify performance differences and informs better purchasing decisions. By mapping these concepts to your production goals, you can evaluate whether a film-forward path aligns with your budget, turnaround, and fabric mix.

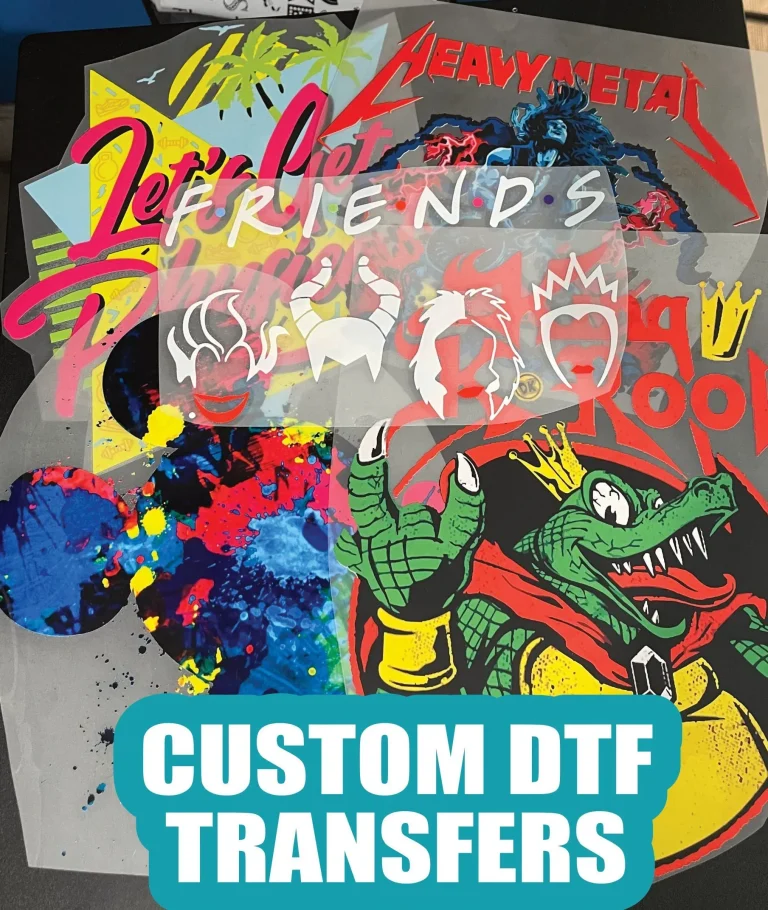

DTF supplies: Selecting the right DTF transfer film, powders, and inks for versatile garment decoration

DTF supplies form the backbone of a reliable transfer workflow. When choosing DTF transfer film, adhesive powder, inks, and curing equipment, you optimize color fidelity, wash durability, and the hand feel of your finished garments. This aligns with the broader topic of direct-to-film supplies and DTF printing, helping you map out a practical starter kit and testing plan.

In practice, the right combination balances film thickness, powder quality, and printer compatibility. The cost-per-unit benefits compound as runs increase, and you can extend your capability across fabrics—from blends to synthetics. The ongoing DTG vs DTF debate is part of a comprehensive printing methods comparison, and by focusing on DTF supplies as a system you improve repeatability and reduce returns.

DTF printing vs other methods: printing methods comparison for shop owners

When evaluating DTF printing against DTG, screen printing, and HTV, it helps to frame a clear printing methods comparison. DTF printing offers full-color, photo-realistic results on a wide fabric range, while DTG shines on cotton with proper pre-treatment and workflow.

Screen printing excels for large-volume runs on cotton, but DTF supplies enable a flexible workflow for smaller batches and designs with multiple colors. HTV remains useful for simple logos, yet DTF printing generally delivers richer color, durability, and a softer look when tuned with the right DTF transfer film and adhesive powder.

Frequently Asked Questions

What are the essential DTF supplies to start DTF printing?

To begin with DTF printing, the core direct-to-film supplies include a compatible printer with DTF inks, DTF transfer film, DTF adhesive powder, a curing device (such as a conveyor dryer or oven), and a heat press. Also consider suitable substrates/fabrics and a compatible bonding agent as needed. The right DTF supplies help ensure color fidelity, durability, and a soft hand feel. Factors like film thickness and powder quality affect adhesion and wash durability, so it’s wise to test a few film and powder options to find what yields consistent results.

How does DTF printing compare with DTG, screen printing, and other printing methods?

DTF printing offers versatile fabric compatibility, full-color capability, and relatively low setup when running multiple or variable designs. In a printing methods comparison, DTG vs DTF shows that DTG can be ideal for 100% cotton with pre-treatment, while DTF works well on blends and synthetics. Screen printing is cost-efficient for very large runs, but requires screens and setup time. DTF transfer film and related supplies enable high-quality, durable transfers across a broad fabric range, with typically quicker turnarounds for small-to-mid runs and less pre-treatment than DTG in many cases.

| Topic | Key Points |

|---|---|

| What is DTF printing and why are DTF supplies important? | DTF uses a film substrate to transfer full-color designs onto fabrics and relies on high-quality supplies (films, powders, glues, and compatible heat presses) to achieve color vibrancy, durability, and a soft hand feel. |

| DTF supplies you’ll likely need | DTF transfer film, DTF printing inks, DTF adhesive powder, curing equipment, heat press, substrates and printers. |

| DTF printing vs DTG | DTF offers versatility across fabrics and easier workflow on non-cotton, while DTG excels on 100% cotton with pre-treatment; each has different setup, costs, and fabric compatibility. |

| DTF printing vs screen printing | Screen printing favors large runs and high-volume output; DTF is better for smaller to mid runs and multi-color designs without extensive screen setup. |

| DTF printing vs HTV | HTV is strong for single-color designs; DTF handles full-color images with better durability and softer edges on many fabrics. |

| Practical workflow tips | Design with color management in mind; print and cure in controlled environments; test before large runs; optimize transfer pressure and temperature; maintain supplies. |

| Starter kit | Printer with DTF inks, DTF transfer film, adhesive powder, curing device, heat press, fabric samples. |

Summary

DTF supplies enable flexible, scalable printing that adapts to a wide range of fabrics and designs. By understanding how DTF printing compares with DTG, screen printing, and HTV, you can tailor your production to the needs of your market—whether you’re a small shop producing custom t-shirts or a larger operation exploring diverse catalog items. The right combination of DTF transfer film, adhesive powder, inks, curing, and heat-press settings will deliver consistent results, improve turnaround times, and expand your options for creative expression. If you’re evaluating which method to adopt, start with DTF supplies and a few trial designs to see how the results meet your expectations for color fidelity, durability, and cost per unit. With careful selection of DTF supplies and a steady workflow, you’ll be able to deliver standout prints that satisfy customers and stand out in a competitive market.