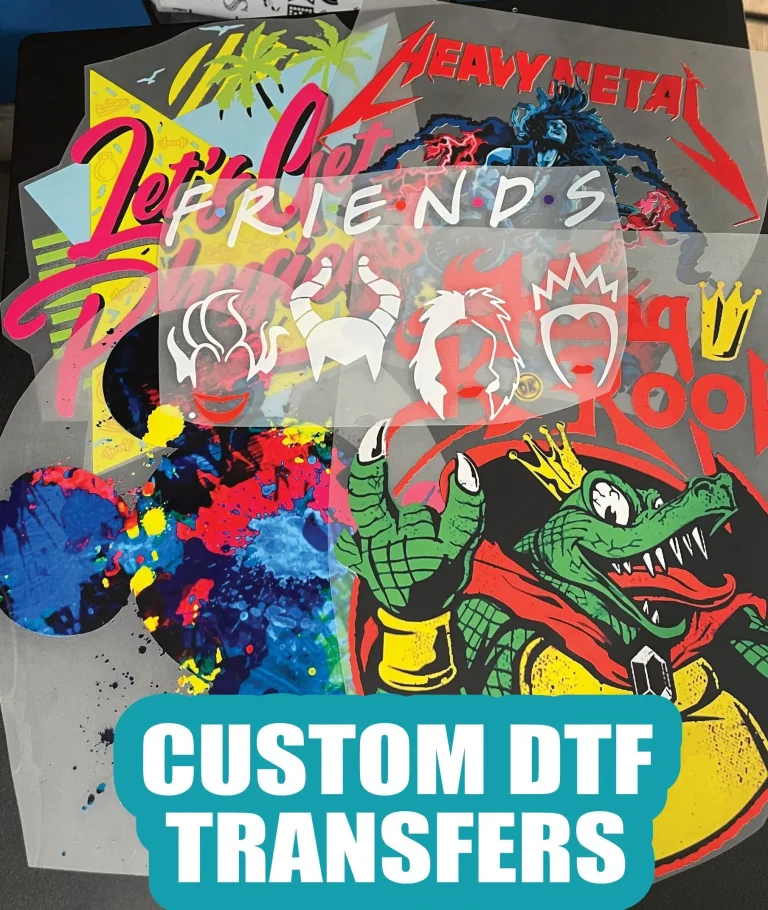

DTF printing, or Direct-to-Film printing, is revolutionizing the fashion industry by offering a cutting-edge solution for custom apparel printing. This technique allows designers to transfer intricate designs onto various fabrics with unmatched vibrancy and quality, all while maintaining cost-effectiveness and efficiency. As fashion technology trends evolve, DTF printing stands out by providing brands with an agile and sustainable method for on-demand fashion production. This not only caters to the growing consumer demand for personalization but also aligns with sustainable fashion printing practices, reducing waste and environmental impact. Embracing DTF printing allows independent designers and established brands alike to keep pace with the dynamic nature of the fashion landscape.

Known as Direct-to-Film printing, DTF printing represents a significant trend shift in textile customization and production. The technique utilizes advanced transfer technology to apply designs directly onto film before heat-pressing them onto fabric, making it efficient for both small and large runs alike. This modern approach integrates seamlessly into the realms of sustainable fashion and on-demand production, creating ample opportunities for brands to innovate. As the appetite for bespoke clothing and quick, eco-friendly fashion solutions grows, DTF printing emerges as a frontrunner in meeting these demands. By harnessing the benefits of DTF technology, fashion brands can elevate their offerings and enhance consumer engagement through tailored apparel.

The Benefits of Direct-to-Film Printing in Sustainable Fashion

Direct-to-Film (DTF) printing represents a significant leap toward sustainable fashion practices. This innovative method reduces the environmental impact typically associated with traditional textile printing, as it utilizes lower amounts of water and minimizes waste. Fashion brands are increasingly prioritizing eco-friendly solutions, and DTF printing fits perfectly within this shift by allowing them to produce high-quality prints without the extensive use of harmful chemicals or excessive resources.

One of the standout features of DTF printing is its ability to enable on-demand production. In an industry notorious for overproduction and waste, brands can rely on DTF technology to create garments that meet current consumer demands without excess inventory. This sustainable approach not only benefits the environment but also aligns with the growing consumer preference for brands that value ecological responsibility.

Custom Apparel Printing: Personalization Meets Technology

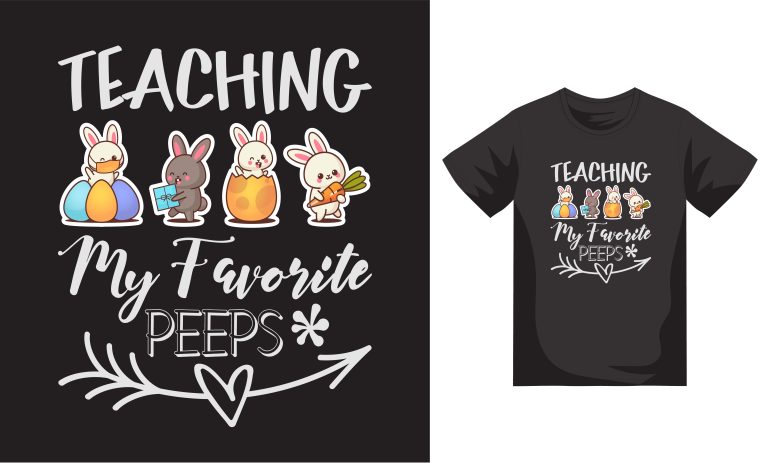

The demand for personalized fashion has surged, with consumers increasingly seeking unique items that reflect their individuality. DTF printing plays a pivotal role in this trend, enabling custom apparel printing that allows brands to offer tailored designs to customers. With the ability to print intricate graphics and text directly onto a wide variety of fabrics, brands can easily adapt their offerings to meet specific consumer requests, effectively standing out in a crowded market.

As fashion technology trends evolve, DTF printing is at the forefront of customization breakthroughs. By harnessing this technology, brands can streamline the design process and quickly turn around personalized products, satisfying the rising expectations of a younger, more discerning clientele. The flexibility afforded by DTF printing not only enhances customer satisfaction but also empowers brands to stay ahead in a fast-changing fashion landscape.

Fashion Technology Trends Shaping the Future of Apparel

DTF printing is one of the key fashion technology trends reshaping the apparel industry, providing brands with the tools they need to innovate. As the fashion industry becomes more tech-driven, DTF offers a seamless integration of design and production, allowing for smoother workflows and more agile business strategies. Fashion labels utilizing this technology can respond to trends more quickly, producing collections that resonate with consumers almost instantaneously.

Additionally, the rise of DTF printing heralds a transformation in how brands view production cycles. By embracing on-demand fashion production, companies can create pieces that reflect current social movements and fashion shifts, minimizing the risk of wastage while maximizing consumer engagement. This approach places them ahead of competitors still relying on outdated production methods, allowing for a more sustainable and trend-responsive market positioning.

Exploring On-Demand Fashion Production with DTF

On-demand fashion production is revolutionizing how garments are made, and DTF printing is at the core of this transformation. Unlike conventional manufacturing processes that require large batches and risk unsold inventory, DTF allows brands to print designs only when orders are placed. This game-changing capability reduces waste and empowers brands to deliver fresh, up-to-date styles without the environmental and financial burdens typically associated with unsold stock.

The flexibility of on-demand production facilitated by DTF printing enables brands to experiment with new designs and styles rapidly. This encourages creativity and innovation, as designers have the freedom to introduce limited-edition collections or exclusive designs tailored to specific customer segments. As fashion consumers increasingly value sustainability and uniqueness, DTF-driven on-demand fashion satisfies both demands beautifully.

Challenges and Solutions in DTF Printing

Despite the numerous advantages of DTF printing, challenges remain that require strategic navigation. One primary concern is the initial investment in DTF technology, which can be significant for small to medium-sized brands. Additionally, mastering the technology demands training and expertise, which can further strain limited resources. However, many companies are overcoming these hurdles through collaborative training initiatives and mentorship programs that enhance skill development within their teams.

Another challenge lies in maintaining quality control as production scales up. Fashion brands must ensure that the vibrant prints produced through DTF technology remain consistent across different fabric types and printing conditions. Establishing rigorous testing protocols and investing in high-quality materials helps brands uphold their reputations for excellence, aligning with consumer expectations for premium custom apparel.

The Future of Fashion with DTF Printing

Looking ahead, DTF printing is poised to play a crucial role in the future of fashion. As technology continues to evolve, so too will the capabilities of DTF printing, allowing for even more intricate designs and faster production times. Brands that adopt this technology will not only be able to cater to the custom apparel market but also engage with consumers in a more authentic and relevant manner by producing items that reflect their values and preferences.

Moreover, the integration of DTF printing with other advancements in fashion technology—such as artificial intelligence and big data—will likely offer brands unprecedented insights into consumer behavior. This data can be leveraged to predict trends and streamline production processes, ensuring that every piece produced resonates with the target audience while staying true to sustainable fashion principles.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct-to-Film printing, involves printing vibrant designs onto a special film that is then transferred onto fabric using heat. This method allows for high-quality, detailed prints on various textiles, making it a popular choice in custom apparel printing.

How does DTF printing contribute to sustainable fashion printing?

DTF printing is considered a sustainable fashion printing method because it uses less water and generates less waste compared to traditional textile printing. Its on-demand production capabilities help reduce excess inventory, aligning with eco-friendly practices in the fashion industry.

What are the main benefits of DTF printing in custom apparel printing?

The main benefits of DTF printing in custom apparel printing include lower setup costs for small runs, quick turnaround times, and the ability to produce intricate, colorful designs that cater to consumer demands for personalization and uniqueness.

Are there any challenges associated with DTF printing technology?

Yes, challenges of DTF printing include the initial investment for equipment and the learning curve required for effective use. Fashion brands often invest in training to ensure they can fully leverage the advantages of DTF technology.

How is DTF printing shaping fashion technology trends?

DTF printing is shaping fashion technology trends by facilitating efficient production processes, promoting sustainability, and enabling brands to respond quickly to emerging trends and consumer preferences, thereby transforming traditional fashion manufacturing.

What role does DTF printing play in on-demand fashion production?

DTF printing plays a significant role in on-demand fashion production by allowing brands to create apparel as needed, reducing excess inventory and waste. This method supports a shift towards more responsive and sustainable production models in the fashion industry.

| Key Development | Description |

|---|---|

| Increased Adoption by Fashion Brands | DTF printing is being readily adopted due to its cost-effectiveness and flexibility, allowing brands to produce small to medium runs quickly, responding to trends effectively. |

| Sustainability Edge | DTF printing uses less water and generates less waste compared to traditional methods, making it a favorable option for environmentally-focused fashion brands. |

| Advancements in Technology | Recent technological enhancements have lowered the costs and improved the usability of DTF printers, driving integration with eco-friendly practices. |

| Customization and Personalization | DTF printing facilitates high levels of customization for consumers, particularly appealing to younger demographics prioritizing personalized apparel. |

| Challenges and Considerations | The high initial costs and the learning curve associated with DTF printing technology present challenges for brands, leading to investments in training. |

Summary

DTF printing is revolutionizing the fashion industry by enabling brands to create vibrant, high-quality designs with remarkable efficiency. This printing method not only drives down costs for short runs, allowing designers to stay on-trend, but also respects the environment by reducing water usage and waste. The technology’s advancements mean that brands can offer greater customization to consumers, meeting the rising demand for personalized apparel, especially among younger buyers. Though challenges remain, such as initial equipment costs, the potential benefits of DTF printing promise a transformative shift towards sustainability and creativity in fashion design.