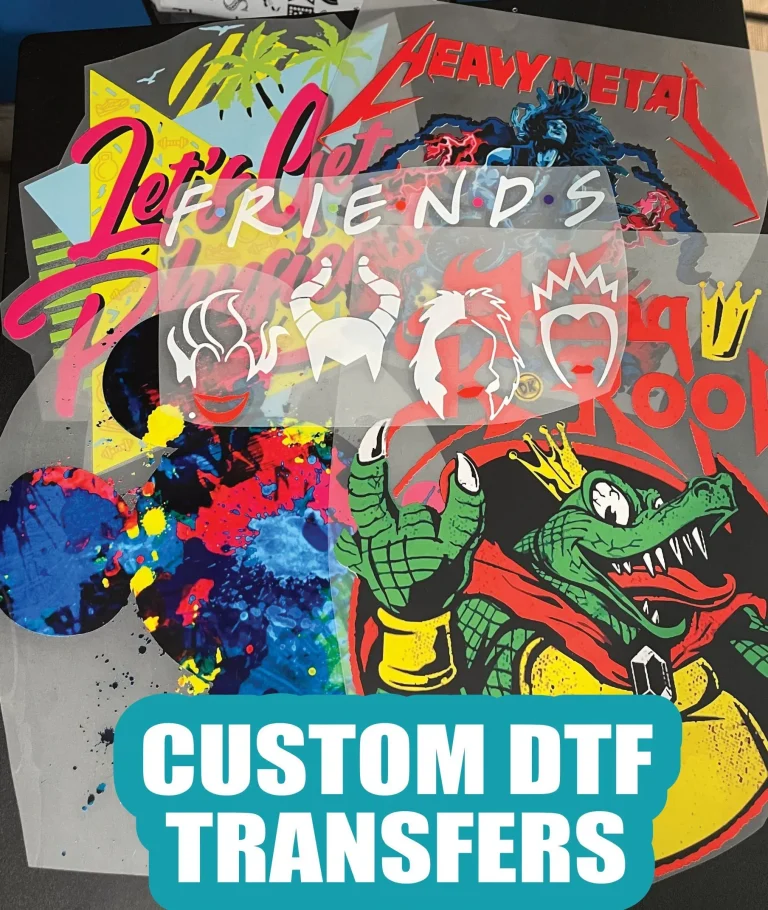

DTF printing supplies are essential for anyone looking to elevate their direct-to-film printing projects. The quality of these supplies—including high-quality transfer films and adhesive powders—plays a significant role in the outcome of your prints. Whether you’re a seasoned professional or just starting, understanding how to choose the right materials can enhance both the vibrancy and durability of your designs. Additionally, maintaining your printer and selecting the best inks are crucial for achieving a flawless finish. In this guide, we will uncover the necessary components for a successful DTF printing experience, ensuring your prints not only look fantastic but also last.

When considering DTF (Direct to Film) printing, it’s important to recognize the implications of utilizing the best film and powder supplies. DTF transfer materials facilitate the process of applying vibrant designs onto various fabrics, while the correct adhesive powders ensure a strong hold between the prints and textile surfaces. For those involved in garment decoration or custom printing, mastering the nuances of ink quality and printer maintenance can be vital in producing impeccable results. As we delve deeper into the world of transfer manufacturing and material selection, we’ll explore how quality supplies like transfer films and adhesive powders can ultimately make or break your printing endeavors.

Understanding DTF Printing Supplies

DTF printing is rapidly gaining popularity among both DIY enthusiasts and professional printers due to its flexibility and quality. Essential DTF printing supplies include transfer films, high-quality inks, and adhesive powders that significantly influence the end product’s durability and vibrancy. Choosing the right supplies can make a distinctive difference in your printing experience, allowing for clearer images and long-lasting designs. By understanding each component’s role, users can optimize their prints to achieve the desired results efficiently.

Investing in top-notch DTF printing supplies is not just about aesthetics; it is also critical to ensuring a smooth workflow. High-quality transfer films, specifically designed for DTF printing, play a vital part in how well ink adheres and transfers to different fabrics. Likewise, using compatible inks and adhesives can substantially reduce issues like fading or peeling, which enhances the final presentation and longevity of the printed items. This holistic approach to selecting DTF printing supplies is essential for anyone serious about quality output.

The Importance of High-Quality Transfer Films

High-quality transfer films are crucial for achieving vivid colors and sharp details in DTF printing. These films are specially formulated to interact properly with DTF inks, allowing for optimal ink transfer and adhesion onto the substrate. When selecting transfer films, it is essential to look for ones that feature a consistent texture and coating, as these attributes ensure even printing and prevent issues like ink bleeding or inadequate adherence. A good film choice not only impacts the print quality but also helps optimize the overall printing process.

Moreover, using the correct transfer films can greatly influence production efficiency. Poor-quality films may lead to more frequent print failures, increased wastage, and time-consuming troubleshooting. By investing in reliable transfer films, printers can enhance their workflow and minimize downtime caused by material inconsistencies. Therefore, thorough research and proper selection of DTF transfer films should be a fundamental part of any DTF printing setup.

Selecting the Right Inks for DTF Printing

Choosing high-quality inks is pivotal to the success of DTF printing. OEM inks are usually designed specifically for certain printer models and tend to produce the best results due to their tested compatibility. However, many third-party options available today offer excellent performance that can match or surpass OEM inks. Conducting tests with different inks allows users to determine which brands consistently yield high-quality prints that align with their expectations.

In addition to compatibility, evaluating the pigmentation and flow characteristics of inks is essential. Pigment-rich inks can provide more vibrant colors and enhance durability, ensuring prints withstand washing and wear over time. Beyond aesthetics, the ink’s viscosity should also be considered, as this affects its flow through the printer’s nozzles, impacting print quality and requiring less maintenance due to fewer clogging issues.

Printer Maintenance for Optimal DTF Output

Regular maintenance of printing equipment cannot be overstated when it comes to DTF printing. Keeping print heads clean and regularly checking for clogs ensures that ink flows smoothly, which translates directly into better print quality. These maintenance practices help prevent common issues, such as color inconsistencies and misalignment, which can compromise the final product. Moreover, consistent upkeep helps prolong the lifespan of printers, providing a better return on investment over time.

Beyond the basics, printer settings must also be adjusted to accommodate the type of ink and transfer film being used. Regularly updating these settings, such as the DPI for precision and ensuring the correct ink density, can greatly impact the quality of DTF prints. A tailored approach to maintenance and settings optimization can lead to impeccable prints that meet the expectations of professional clients and hobbyists alike.

Maximizing Adhesion with Adhesive Powders

Adhesive powders are a critical component in the DTF printing process, acting as the binding agent that ensures prints adhere well to their designated fabrics. The choice of adhesive powder can vary significantly based on the type of material being printed on, as different fabrics may require different adhesive properties to achieve a strong bond. Conducting tests with various adhesive powders is recommended to find the right solution that guarantees durability and permanence.

Moreover, the technique used to apply adhesive powders is also vital for successful adhesion. Effective heat application and ensuring that the powders are evenly distributed during the transfer process can significantly enhance the strength of the bond between the printed design and the fabric. Paying attention to these details when using adhesive powders can make a notable difference in the quality and longevity of DTF prints.

Optimizing DTF Printing Workflow

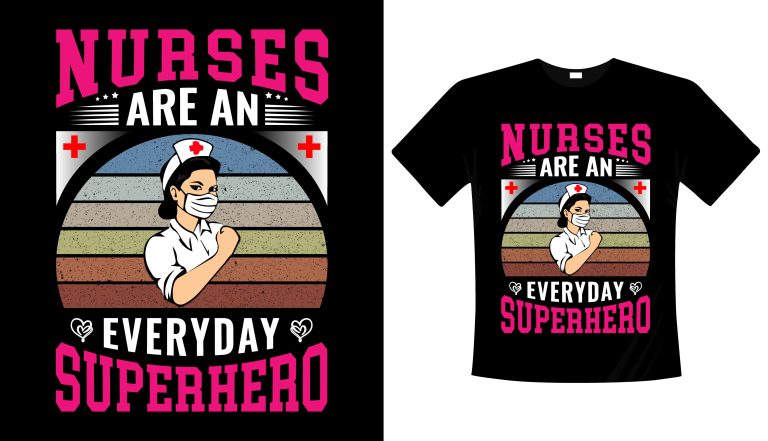

To achieve consistent, high-quality results in DTF printing, optimizing your workflow is essential. This includes preparing your designs efficiently, selecting the correct supplies, and ensuring your equipment is functioning at its peak. Utilizing design software to pre-visualize prints can save significant time by allowing adjustments before actual printing begins. Additionally, maintaining a clean and organized workspace can streamline the process and reduce the chance of errors.

Incorporating training and best practices into your workflow further boosts efficiency. Keeping up with industry trends and advancements in DTF technology can enhance skills and knowledge, allowing for innovative approaches to printing. Regularly revisiting and revising workflow processes based on what yields the best results can contribute to a more productive and high-quality printing operation.

Frequently Asked Questions

What are the essential DTF printing supplies for achieving quality prints?

Key DTF printing supplies include high-quality DTF transfer films, OEM or high-quality inks, adhesive powders for fabric bonding, and proper printer maintenance tools. Selecting the right combination ensures vibrant, durable prints that adhere well to your fabrics.

How does the quality of transfer films impact DTF printing results?

The quality of transfer films directly affects print vibrancy and durability in DTF printing. High-quality films enhance color brightness and improve ink adherence, resulting in superior final products. Always opt for films designed specifically for DTF printing.

What types of adhesive powders should I use for DTF printing?

Using the right adhesive powders is crucial in DTF printing, as different fabrics require specific types. Test various adhesive powders to find the best option that provides strong adhesion and durability for your chosen materials.

How can I maintain my printer for optimal DTF printing performance?

Regular printer maintenance is vital for DTF printing. This includes cleaning print heads, checking for clogs, and ensuring proper ink flow. A well-maintained printer leads to consistent print quality and longevity, reducing downtime.

What temperature and pressure settings are recommended for DTF printing?

For optimal DTF transfer, set your heat press between 300°F to 340°F (150°C to 170°C) and apply consistent pressure as per the manufacturer’s guidelines. Correct settings are crucial for ensuring proper adhesion and print durability.

Why is pre-treatment important for fabrics in DTF printing?

Pre-treating fabrics is essential in DTF printing to enhance ink adhesion and minimize issues like cracking or peeling. Washing fabrics to remove sizes and finishes ensures a clean surface, leading to better print quality and longevity.

| Key Points | Details |

|---|---|

| Direct to Film (DTF) Printing | A revolutionary method for transferring designs to fabrics with high quality and versatility. |

Summary

DTF printing supplies play a pivotal role in elevating the quality and durability of your prints. By selecting the right transfer films and inks, configuring your printer settings meticulously, and utilizing appropriate adhesives, you can achieve exceptional results. Additionally, paying attention to fabric pre-treatment, post-processing care, and color optimization ensures that your final products not only look great but will stand the test of time. Understanding and properly utilizing these DTF printing supplies can significantly enhance your capabilities, enabling you to produce stunning apparel that meets industry standards and satisfies customer expectations.