DTF Printing Materials are pivotal in revolutionizing the landscape of modern printing technology. As the demand for high-quality prints grows, DTF (Direct-to-Film) printing has established itself as a preferred choice due to its efficiency and versatility. With specialized DTF inks and transfer films for DTF, this innovative technique allows for vibrant designs to be applied onto a variety of surfaces seamlessly. The use of gang sheets in DTF printing further enhances the efficiency of the printing process by maximizing material usage while minimizing waste. In this article, we will delve into the essential components of DTF printing materials and how they contribute to producing stunning, durable prints that meet today’s standards.

When discussing printing technologies, alternative terms such as direct-to-film printing and DTF film production often arise. This method utilizes specialized inks and films tailored for outstanding performance in various applications. The materials involved play a crucial role in ensuring the longevity and vibrancy of the final product. Moreover, the concept of gang sheets, which optimizes print production by consolidating multiple designs, showcases the ingenuity present in the DTF process. As we explore these aspects further, it becomes clear that understanding these factors is key to leveraging DTF printing materials effectively.

The Importance of Quality DTF Inks

In the DTF printing process, the type of inks used is paramount to achieving vibrant, high-quality prints. DTF inks should be specially formulated to ensure compatibility with the transfer films and substrates. High-quality DTF inks not only provide excellent color vibrancy but also guarantee longevity, crucial for designs subjected to wear and tear. Inks that adhere properly to the transfer films utilized in DTF printing ensure that the designs are firmly transferred with minimal smudging or fading, making them an essential consideration for anyone involved in this printing method.

Furthermore, different ink formulations can affect the overall durability of prints on various materials. For instance, inks that are resistant to moisture and UV light are particularly important for items such as outdoor apparel. Evaluating the market for inks that incorporate advanced technology, like those used in the LOKLiK iPrinter DTF, assures a balance between richness of color and resistance to environmental factors, ultimately leading to professional-grade results for your printing projects.

Evaluating Transfer Films for DTF Success

Transfer films serve as a crucial component in DTF printing, acting as the medium through which designs are output onto various surfaces. It is vital to select high-quality transfer films that permit optimal ink absorption and release, as the attributes of the film directly impact print quality. Factors such as thickness, opacity, and surface texture can make significant differences in the end product. Choosing specialized films designed for DTF printing, like those associated with reputable brands, ensures that the transferred designs maintain integrity and vibrancy.

Additionally, proficient use of transfer films can enhance operational efficiency by minimizing wasted materials. Films that perform well allow for cleaner prints and smoother transfers, effectively catering to the specific needs of the business. The right choice in transfer films not only ensures high-quality results but also facilitates higher productivity levels. Therefore, understanding the varieties of transfer films available, and matching them with the right printer and inks, creates a synchronized process pivotal for successful DTF printing.

Maximizing Efficiency with Gang Sheets

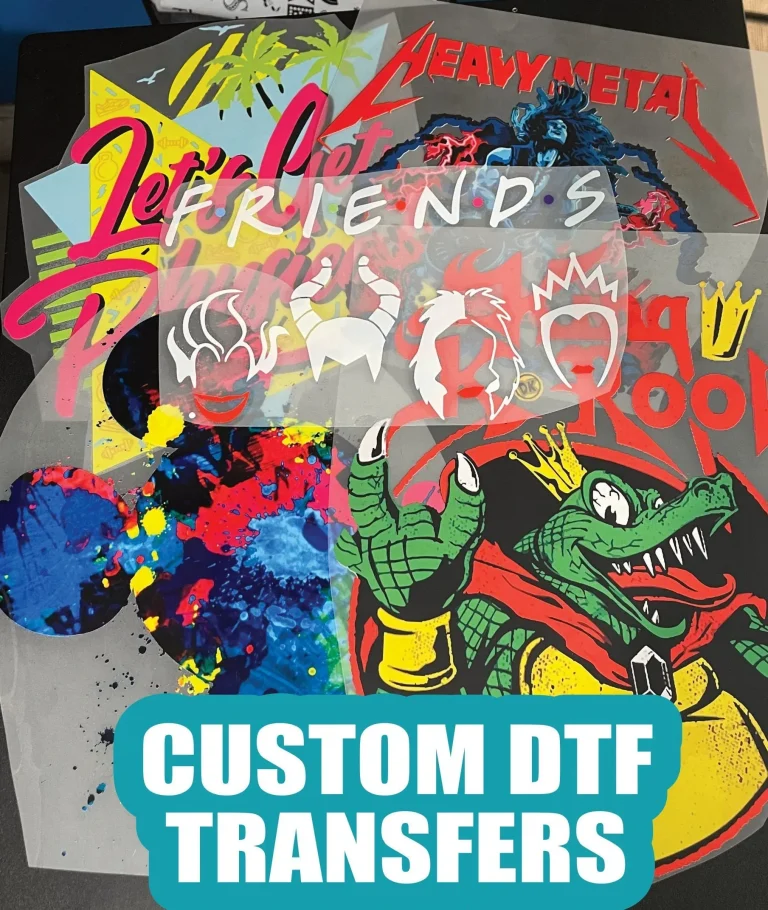

The use of gang sheets is an innovative strategy in DTF printing, allowing multiple designs to be printed simultaneously on a single sheet of transfer film. This not only saves on material costs but also significantly increases efficiency, making it an excellent practice for businesses aiming to optimize resource utilization. By familiarizing oneself with the creation and application of gang sheets, printers can streamline their workflow, minimizing downtime and maximizing throughput.

Additionally, ganging designs together reduces ink waste and enables better management of printing resources. It’s possible to experiment with different designs to cater to customer demands without incurring additional material costs. This approach not only benefits printing operations economically but also allows for increased flexibility in design offerings, fulfilling varied client needs while maintaining high output levels.

Selecting the Right Printer for DTF Applications

Choosing the right printer is critical to the success of any DTF printing operation. Factors such as printer type, size, and compatibility with specific DTF inks and transfer films play an essential role in determining the quality of the final product. Printers, like the LOKLiK iPrinter DTF, offer features tailored to the requirements of DTF printing, such as precise ink application and customizable settings that enhance print clarity.

Investing in an appropriate printer aligns with the operational capacity and specific printing needs of the business. Quality printers can also significantly reduce the margin for error during production, ensuring consistency across multiple print runs. By doing thorough research on printer technologies and features, businesses can find models that not only enhance efficiency but also contribute to achieving high-quality, standout prints.

Innovations Shaping the Future of DTF Printing

The DTF printing landscape is witnessing rapid technological advancements that are continuously enhancing printing processes. Recent innovations, such as the introduction of web-to-print platforms like the Snuggle DTF platform, have simplified the accessibility of DTF technologies for commercial printers and resellers. These platforms allow individuals and businesses to navigate the complexities of DTF printing more effectively, from material selection to streamlined ordering processes.

Moreover, advancements in ink formulations and transfer film technologies are making it easier to achieve vibrant, durable designs that appeal to a wide range of applications. These innovations promise to attract more users to DTF printing, expanding market reach and increasing competition. Staying abreast of these developments not only helps businesses adopt more efficient practices but also ensures continued growth and adaptation in an ever-evolving printing industry.

Choosing Reliable Suppliers for DTF Materials

Selecting reputable suppliers for DTF printing materials is fundamental to the quality of output and overall success in the printing business. When sourcing DTF inks, films, and printers, it is critical to choose suppliers that are recognized for their high-quality products and reliability. Researching suppliers, reading reviews, and engaging with other printing professionals can provide insights into which suppliers consistently meet industry standards.

A reliable supplier will not only provide the products necessary for maintaining quality in DTF printing but also offer valuable support and advice, helping businesses make informed decisions. Establishing a relationship with trusted suppliers ensures that you have access to the best available materials and innovations within the DTF printing sector, which is vital for achieving superior prints and maintaining a competitive edge.

Frequently Asked Questions

What are the essential DTF printing materials for beginners?

The essential DTF printing materials for beginners include DTF inks, transfer films for DTF, and a compatible printer. DTF inks should be specially formulated for vibrant and durable results. Transfer films act as the medium for ink before the final transfer to fabrics, while the right printer ensures precise ink application.

How do DTF inks affect print quality in DTF printing technology?

DTF inks significantly influence print quality in DTF printing technology. High-quality DTF inks enhance color vibrancy, adhesion, and durability of prints. Choosing the right inks will directly impact the longevity and appearance of the final printed design, making them a crucial factor for any printer.

What role do transfer films play in direct-to-film printing?

In direct-to-film printing, transfer films provide the substrate where the DTF inks are printed before being transferred to the final material. The quality of transfer films is vital as they affect ink absorption and release, ultimately determining the clarity and professionalism of the print.

What are gang sheets in DTF printing, and why are they important?

Gang sheets in DTF printing refer to a method where multiple designs are printed on a single film sheet. This technique optimizes ink usage and minimizes waste, making it crucial for efficient production and cost-effectiveness in print jobs, especially for businesses seeking to improve resource management.

How can I choose the right printer for DTF printing?

Choosing the right printer for DTF printing involves considering compatibility with DTF inks, precision in ink application, and overall efficiency. Look for printers that come with necessary supplies and innovations that enhance printing capabilities for quality and consistency in results.

Where can I find reliable suppliers for DTF printing materials?

You can find reliable suppliers for DTF printing materials by researching providers known for their high-quality DTF inks, transfer films, and printers. Reading reviews and seeking recommendations from the DTF printing community can help ensure you partner with suppliers who align with industry standards.

| Key DTF Materials | Importance | Recent Innovations |

|---|---|---|

| DTF Inks | Determines vibrancy and longevity of prints. | LOKLiK iPrinter DTF with high-quality inks. |

| Transfer Films | Significantly impacts print outcome; ensure proper ink absorption. | Films recommended for A3 DTF Printer from AM.CO.ZA. |

| Gang Sheets | Minimizes waste and enhances printing efficiency. | Guides on gang sheets can improve resource management. |

| Printer Selection | Foundational for achieving quality prints. | LOKLiK iPrinter DTF for newcomers with included supplies. |

| Trusted Suppliers | Critical for ensuring quality materials and advice. | Research suppliers to align with industry standards. |

Summary

DTF Printing Materials are essential for anyone looking to achieve high-quality prints through this modern technology. By understanding the various components like DTF inks, transfer films, and printers, you can significantly enhance the quality and durability of your printed designs. Innovations such as gang sheets optimize material usage while recent advancements in technology make the process more accessible. Therefore, prioritizing quality in your DTF materials and partnering with reliable suppliers are key steps to ensure exceptional results in your printing endeavors.