DTF Printing is reshaping how apparel and textile designers bring vivid, durable artwork to life. As Direct-to-Film transfers gain traction, studios across creative hubs seek scalable workflows that deliver accurate colors, strong adhesion, and a soft hand-feel on diverse fabrics, while also simplifying ink management, batch consistency, and post-press quality checks. Understanding the broader DTF workflow helps brands optimize printer choices, film options, and heat-transfer settings to meet changing demand, while comparing costs, lead times, and reliability across different suppliers. For California-based operations, this approach offers flexible production, faster prototyping, and cost-effective expansion without sacrificing quality, enabling on-demand runs for seasonal drops, promotions, and custom collaborations with local retailers. From beginners exploring entry-level equipment to established shops upgrading their lineup, this guide helps you make informed decisions through practical checklists, trusted vendor recommendations, and real-world workflow examples.

Beyond the formal name, the concept centers on transferring ready-made designs from a printed film to fabric using heat, yielding durable, photo-like graphics. To achieve this, printers optimize color management, substrate compatibility, and curing methods to deliver vibrant results on a wide range of textiles. Think of it as a digital-to-fabric workflow that leverages film media and adhesive layers to provide customizable apparel with fast turnaround. As technology evolves, suppliers focus on film types, white ink opacity, and streamlined curing to support on-demand production.

DTF Printing in Focus: What Direct-to-Film Transfers Bring to Apparel

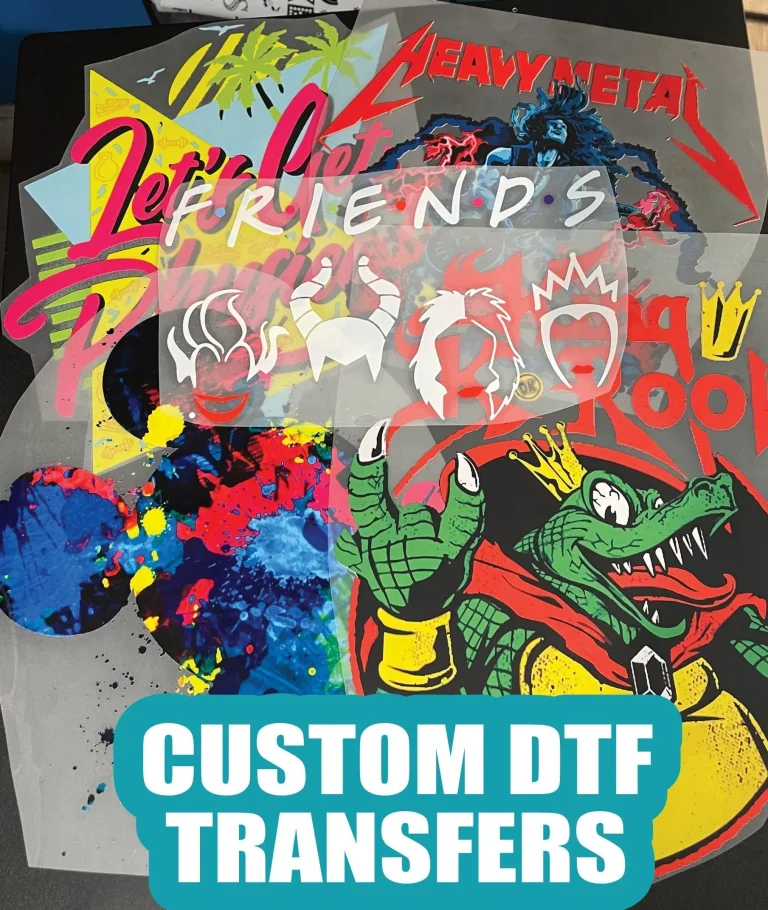

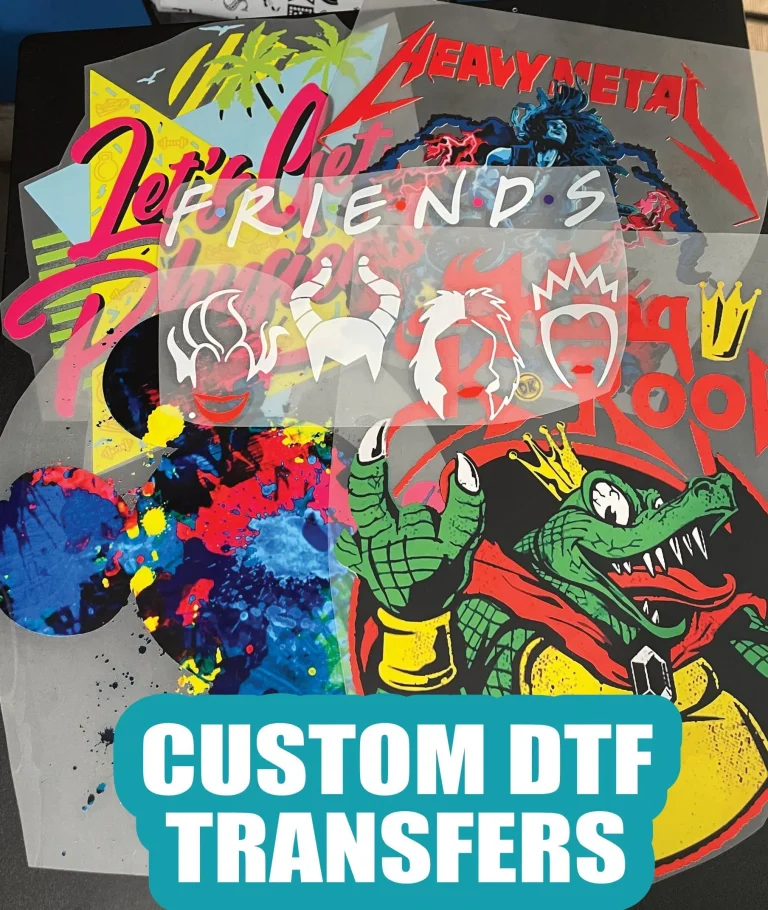

DTF Printing, also known as Direct-to-Film transfers, is reshaping how brands decorate fabrics by printing designs onto a PET film and then transferring them with heat. This approach delivers vibrant color, soft hand-feel, and durable wash performance across cotton, blends, and synthetics. For California designers and shops, DTF transfers enable fast prototyping, on-demand production, and scalable runs without the lengthy setup commonly associated with traditional screen printing.

In practice, the DTF printing process centers on a digital-to-film workflow that blends high-resolution print quality with an adhesive powder and heat transfer. By carefully selecting film, powder, and curing steps, shops can maintain consistent color reproduction and edge definition across batches. This makes Direct-to-Film transfers a compelling option for California markets with diverse fabrics and production needs.

The DTF Printing Process: Step-by-Step Guide for Consistent Results

The DTF printing process starts with artwork prepared using calibrated color profiles and registration guides to minimize misregistration. Careful pre-press planning helps ensure the image sits correctly within garment areas and scales well across sizes.

The design is then printed onto Specialty PET film using a DTF-compatible printer with CMYK inks, often with white to achieve opacity on dark fabrics. After printing, adhesive powder is applied, the film is cured, and finally transferred to the garment with a heat press, followed by any post-transfer finishing steps to maximize durability.

Choosing the Right Equipment and DTF Supplies for California Shops

A reliable DTF workflow starts with a robust DTF printer capable of laying down vibrant color and dense white ink where needed. Select printers with stable ink chemistry, dependable maintenance, and compatible RIP software to keep color fidelity high in California production environments.

You’ll also need Specialty PET film, hot-melt adhesive powder, and a dependable curing and finishing setup. The core cluster of DTF supplies and equipment—along with a capable heat press and clean room practices—forms the backbone of a consistent, scalable Direct-to-Film operation in any California shop.

Design and Color Management for Vivid DTF Transfers

Color management is central to delivering consistent DTF transfers. Use calibrated color profiles and plan white-ink layering to maximize opacity on dark fabrics, ensuring the final print matches the client’s branding in California markets.

Attention to image resolution, color separation, and overprint settings helps preserve detail and prevent color bleed during transfer. Testing on representative fabrics—such as cottons, blends, and performance textiles—ensures that color, saturation, and edge definition remain reliable across orders and garment types.

DTF vs Other Transfer Methods: When to Choose Direct-to-Film in California

DTF transfers offer versatility across a wide fabric range, with strong color fidelity and durability that often outperform traditional heat transfers on synthetic blends. Compared to DTG, DTF can be more cost-effective for small to mid-volume runs and is less sensitive to fabric type, making it appealing for California brands with varied materials.

DTF also compares favorably to screen-printing for on-demand or low-to-mid-volume projects due to faster setup and easier changes. The choice often hinges on run size, fabric mix, and desired hand-feel, with California shops frequently leaning toward DTF for its blend of flexibility and dependable wash performance.

Practical Tips for California-Based DTF Printing Businesses

California-facing printers should leverage local supplier networks for films, powders, and pre-treatment products to reduce lead times and support rapid fulfillment for campaigns and events. Aligning with regional distributors can improve stock consistency and service levels across the state.

Invest in color management, energy-efficient curing options, and compliant labeling practices to meet California’s environmental and regulatory expectations. Regular maintenance, test prints, and clear client education help manage expectations and minimize rework, ensuring steady growth in a competitive market.

Frequently Asked Questions

What is DTF Printing and how do Direct-to-Film transfers work?

DTF Printing, or Direct-to-Film transfers, involves printing designs onto a PET film, applying hot-melt adhesive powder, curing, and transferring the image to fabric with heat. The result is vibrant color, good wash durability, and compatibility with most fabrics. The process enables flexible, on-demand production suitable for California boutiques and schools.

What equipment and supplies do I need for DTF printing (DTF supplies and equipment)?

Key items include a DTF printer with CMYK (and white) inks and a compatible RIP, specialty PET transfer film, hot-melt adhesive powder, a curing setup, and a heat press. Optional pre-treatment for certain fabrics and color-management tools help ensure consistency across batches.

How does the DTF printing process compare with DTG or traditional heat transfers?

DTF printing process offers flexibility across fabrics (cotton, blends, synthetics) and generally lower setup costs for small runs than screen printing, with strong durability and color fidelity. DTG may yield great results on natural fibers but can be fabric-sensitive; traditional heat transfers can be slower or less scalable. DTF transfers also enable on-demand production with relatively quick turnaround.

Why is DTF Printing a strong option for California DTF printing shops?

In California, DTF Printing delivers vibrant colors, soft hand feel, and reliable performance on a wide fabric range, meeting demand from boutiques and events. Local supplier networks, sustainable options, and compliance considerations support efficient workflows. The method’s flexibility supports on-demand orders common in California markets.

How can I ensure color accuracy and durability in the DTF printing process?

Start with proper color management, calibration, and white ink layering when printing designs. Use the right PET film, optimize ink densities via RIP, and tailor curing temperature and dwell time to the film and fabric. After transfer, ensure correct heat-press settings and allow adequate cooling for durability.

What are common challenges with DTF transfers and how can I troubleshoot them?

Common issues include misregistration, uneven powder application, and poor adhesion due to improper curing. Solutions: align film and garment with templates, use controlled powder application, verify consistent curing temperatures, and perform test prints before large runs. Regular maintenance of printheads and film handling helps prevent quality dips.

| Topic | Key Points |

|---|---|

| What is DTF Printing? |

|

| How Direct-to-Film Transfers Work |

|

| DTF Printing Process: Step-by-Step |

|

| Equipment and Materials |

|

| Design and Color Considerations |

|

| DTF vs Other Transfer Methods |

|

| California Market: Practical Tips |

|

| Practical Tips, Troubleshooting, and Best Practices |

|

| Common Pitfalls and How to Avoid Them |

|

| The Future of DTF Transfers |

|

Summary

Table summarizes the key points about DTF Printing based on the provided base content. The HTML table highlights what DTF Printing is, how it works, the step-by-step process, required equipment and materials, design and color considerations, comparisons with other transfer methods, California market tips, practical troubleshooting advice, common pitfalls, and future trends.