The DTF Gangsheet Builder represents a revolutionary approach in the textile printing industry, combining modern technology with the unique benefits of direct-to-film printing. Unlike traditional printing methods such as screen printing, the DTF Gangsheet Builder enhances printing efficiency by allowing multiple designs to be printed on a single sheet, a game-changer for businesses requiring versatility and speed. This innovative solution not only reduces material waste but also minimizes costs, making it a more cost-effective printing option for bulk orders. As brands seek to navigate the demanding landscape of custom apparel, the DTF Gangsheet Builder is becoming an essential tool to meet various printing needs. Whether you’re a small business owner or a seasoned printer, understanding the impact of DTF printing can help elevate your production capabilities significantly.

In today’s rapidly evolving printing landscape, the DTF Gangsheet Builder offers an exciting alternative to longstanding processes like screen printing and heat transfer vinyl. Known for its ability to streamline production through direct-to-film technology, the DTF builder enhances operational efficiency and caters to a variety of printing demands. This method not only supports intricate designs with superb detail but also encourages a more environmentally friendly approach to printing by minimizing waste. As customization becomes increasingly crucial for consumers, utilizing gangsheet builders may provide the flexibility and cost savings businesses need to thrive. Embracing this contemporary printing solution may very well position you at the forefront of the textile printing revolution.

The Advantages of DTF Printing Technology

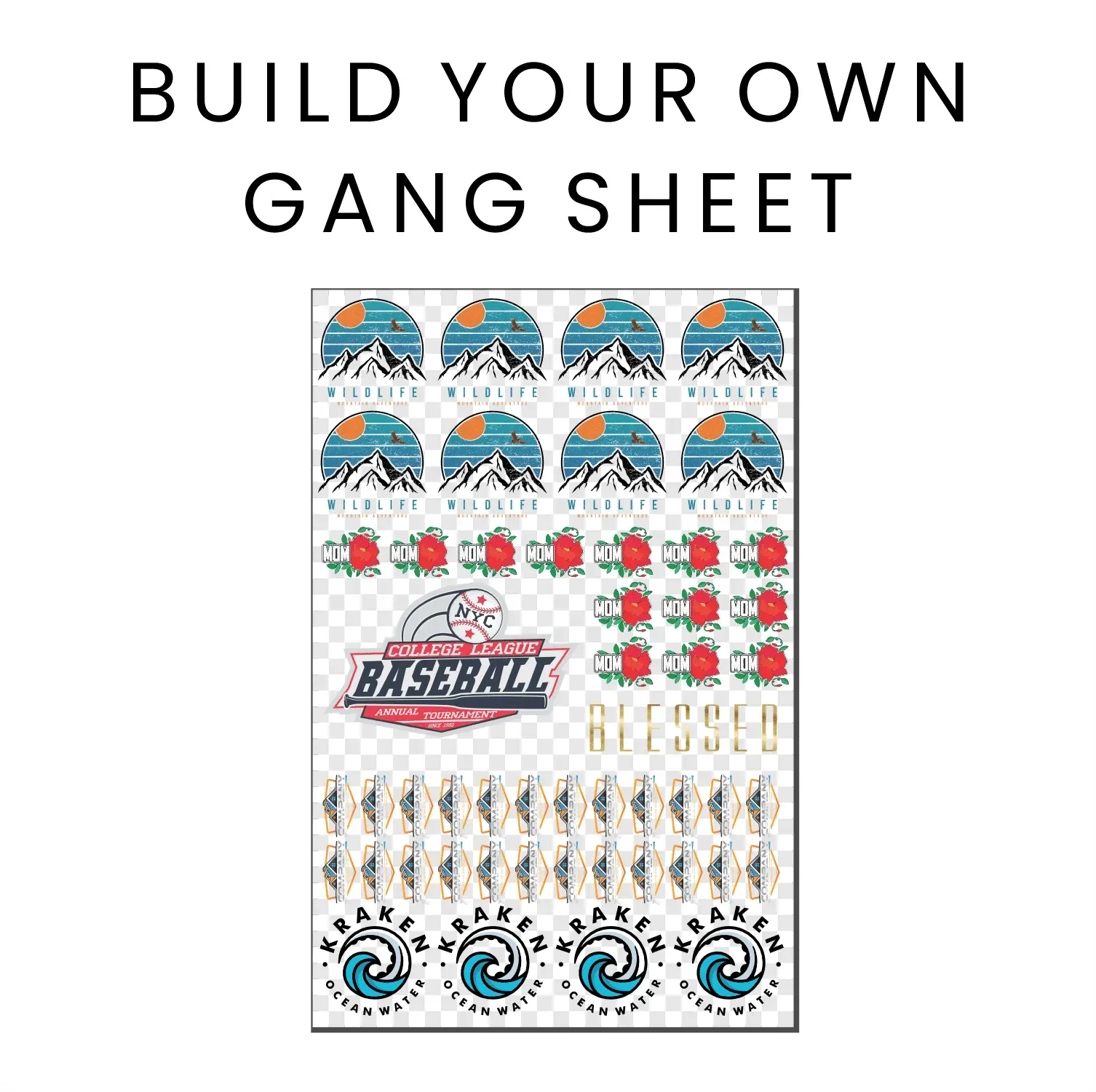

DTF printing technology offers several notable advantages that are redefining the textile printing industry. One of its primary benefits is its unmatched efficiency. By allowing multiple designs to be printed on a single film, DTF gangsheet builders significantly minimize setup times and reduce material waste. This means that businesses can process orders much faster, which is critical in meeting market demands, particularly during peak seasons. Additionally, DTF printing supports personalized apparel production, making it an ideal choice for small businesses looking to cater to unique customer requests.

Another key advantage is the cost-effectiveness of DTF printing. Since multiple designs can be printed simultaneously on a gang sheet, the per-unit cost decreases, creating savings especially beneficial for bulk orders. This efficiency helps businesses remain competitive in a market where printing costs are constantly scrutinized. Moreover, the vibrant and intricate designs achievable with DTF technology attract customers who seek high-quality, detailed prints that traditional methods often struggle to deliver.

Comparing DTF Gangsheet Builders and Screen Printing

When comparing DTF gangsheet builders with traditional screen printing methods, several factors come into play. Screen printing has long been celebrated for its durability and quality, particularly with large batches of the same design. This method’s ability to produce rich, vivid colors aligns well with the demands of businesses that prioritize sturdiness, especially for solid designs. However, the rigidity in adapting to varied designs presents a challenge as custom printing becomes increasingly popular.

Conversely, DTF gangsheet builders shine in their adaptability, allowing for a wider variety of designs and prints on different materials. This flexibility makes DTF particularly appealing for small to medium-sized enterprises that thrive on diversity in offerings. The ease of use in DTF printing also reduces the need for extensive training, making it accessible for newcomers to the industry. While screen printing may continue to dominate in certain areas, the growing trend towards individualized designs favors the swift adaptability and low setup costs associated with DTF.

The Cost-Effectiveness of DTF vs Traditional Methods

Cost considerations are pivotal when selecting a printing method, and this is where DTF printing often has an edge over traditional methods. In traditional screen printing, while the costs can be lower for large, homogenous runs, the initial setup, including the creation of screens and inks, can be quite costly and time-consuming. This initial investment can deter smaller businesses or those with fluctuating order sizes. DTF printing, on the other hand, allows for economical small-batch runs, making high-quality printing accessible without hefty upfront costs.

Moreover, DTF printing’s cost-effectiveness extends beyond just the first production phase. Efficiency in using materials and reducing waste translates into lower operational costs over time. For example, printing multiple designs on a single sheet minimizes the ink and film used, further enhancing profitability for businesses. The ability to accommodate unique customer requests without significant financial risk is an attractive feature that makes DTF an economically sensible choice for many.

Durability and Quality: Traditional Methods vs DTF

In the debate of durability and print quality, traditional screen printing holds a strong reputation. This method excels at producing crisp, vibrant prints that withstand the rigors of washing and wear, especially when solid colors are used. Brands that prioritize long-lasting apparel often lean toward screen printing for its reliability in producing uniformity and quality across extended runs. The rich texture of screen-printed designs can enhance the perception of value among customers, making it a preferred choice for premium apparel.

However, the versatility offered by DTF printing is catching up rapidly. While it may not traditionally rival screen printing on the durability aspect, the advancements in DTF technology have led to improved resilience in prints capable of retaining their vibrancy over time. Additionally, DTF excels in detailed designs and color gradients that traditional methods may struggle to produce. For brands wishing to push the envelope with intricate artwork, DTF gangsheet builders allow for creative freedom without compromising on quality.

How to Choose the Right Printing Method for Your Business

Deciding between DTF gangsheet builders and traditional printing methods should be an informed choice based on specific business needs. If your operations require a fast turnaround with a variety of designs, DTF printing stands out as the more practical option. The flexibility it offers enables businesses to respond swiftly to market trends and customer demands, ensuring that they remain competitive in a rapidly evolving landscape. For businesses catering predominantly to bulk orders with established designs, traditional screen printing remains a viable option due to its efficiency and low cost for large runs.

Furthermore, consider your target audience’s preferences and the types of products you wish to offer. If your customer base is leaning towards custom apparel that reflects individual styles or limited-time designs, investing in DTF technology can provide a significant advantage. Conversely, if your brand is known for high-quality, consistent designs, especially in solid colors, sticking with traditional methods may reinforce your brand identity. In the end, aligning your printing method with your overall business strategy is essential for long-term success.

Future Trends in Textile Printing Technologies

The textile printing industry is witnessing a significant shift towards innovative technologies, with DTF gangsheet builders at the forefront of this evolution. As consumer demand for customization and quick fulfillment continues to rise, businesses are increasingly inclined to adopt direct-to-film printing methods that allow for agility and versatility. As manufacturers continue to refine DTF technology, we can expect enhancements in print quality and durability that further bridge the gap with traditional methods, enabling a new standard in textile printing.

Moreover, sustainability is becoming more critical in consumer purchasing decisions, and DTF printing’s reduced environmental impact makes it an appealing choice for eco-conscious brands. As more companies aim to minimize waste and use fewer resources, the shift towards DTF will likely gain momentum. This trend is not only beneficial for businesses but also for meeting customer expectations in an increasingly values-driven market. By embracing innovative printing technologies, companies can position themselves for success in a dynamic and competitive landscape.

Frequently Asked Questions

What is a DTF Gangsheet Builder and how does it differ from traditional printing methods?

A DTF Gangsheet Builder is a tool used in Direct-to-Film (DTF) printing to create sheets that can accommodate multiple designs, allowing for efficient printing and reduced material waste. Unlike traditional printing methods such as screen printing, which often involves longer setup times and is best suited for bulk orders of identical designs, DTF gangsheet builders are designed for quick, customizable production runs across various fabric types.

Can DTF Gangsheet Builders produce high-quality prints compared to traditional screen printing?

Yes, DTF gangsheet builders can produce high-quality prints, often surpassing traditional screen printing in terms of detail and color vibrancy. DTF technology allows for intricate designs and gradients that might be difficult to achieve with screen printing, making it an appealing option for custom apparel and personalized products.

How does DTF printing improve printing efficiency compared to traditional methods?

DTF printing enhances printing efficiency by enabling the production of multiple designs on a single film sheet, minimizing setup time and reducing material waste. This contrasts sharply with traditional methods like screen printing, which can require significant setup for each design, leading to longer turnaround times.

Is DTF Gangsheet Builder a cost-effective printing solution for small businesses?

Absolutely! DTF gangsheet builders offer a cost-effective printing solution for small businesses by reducing per-design costs through the ability to print multiple designs simultaneously. This is particularly advantageous for small batch orders where traditional screen printing may not be as economical.

What materials can be printed using DTF Gangsheet Builders compared to traditional methods?

DTF gangsheet builders are versatile and can print on various materials, including cotton, polyester, and blends, expanding the range of products you can create. Traditional methods, particularly screen printing, may be limited in their adaptability to different fabrics and detailed designs.

What should I consider when choosing between a DTF Gangsheet Builder and traditional printing methods?

When choosing between a DTF gangsheet builder and traditional printing methods, consider factors such as production speed, volume of orders, design complexity, and material types. DTF is ideal for quick, flexible printing needs with varied designs, while traditional methods excel in high-volume production of simple, solid color designs.

| Comparison Factor | DTF Gangsheet Builder | Traditional Methods |

|---|---|---|

| Efficiency | Creates sheets with multiple designs, reducing setup time and material waste. | Longer setup time due to screen production and setup requirements. |

| Cost-Effectiveness | Lower cost per design, ideal for bulk orders. | More cost-effective for high volume of the same design. |

| Quality of Prints | Enables intricate designs with high details and gradients. | Produces vibrant, durable prints that maintain quality over time. |

| Ease of Use | Requires less technical expertise, more accessible for newcomers. | Requires thorough training, particularly in preparing screens and ink management. |

| Versatility | Can print on diverse materials like cotton and polyester, enabling a wide product range. | Limited adaptability to multiple fabric types, excels mainly in solid colors. |

Summary

DTF Gangsheet Builder serves as a modern and efficient solution for textile printing compared to traditional methods. With its ability to produce multiple designs on a single film, it provides significant advantages in terms of speed and cost savings. The versatility of DTF printing not only opens opportunities for various fabric types but also ensures high-quality outputs that meet consumer demands for customization. As businesses navigate the evolving market landscape, adopting DTF gangsheet builders allows for a competitive edge through innovative printing strategies. Ultimately, understanding your specific needs and aligning them with the benefits of DTF technology can lead to more effective and successful printing operations.