The DTF Gangsheet Builder is revolutionizing the textile printing landscape, offering businesses an innovative solution that combines efficiency with versatility. As the textile industry transitions away from traditional printing methods, this technology stands out for its impressive cost-effectiveness, enabling producers to maximize their investment with minimal waste. One of the standout features of the DTF process is its design flexibility, allowing intricate graphics to be printed on a variety of materials. Coupled with sustainability in printing, the DTF Gangsheet Builder represents a modern approach that not only caters to aesthetic demands but also supports eco-friendly practices. This article delves deeply into the advantages of DTF Gangsheet Builders, comparing them to conventional methods to showcase their potential in transforming how products are printed.

Direct to Film (DTF) Gangsheet Builders are setting new benchmarks in the printing sector, particularly when juxtaposed with established techniques like screen printing and offset printing. By embracing these cutting-edge builders, businesses can enjoy greater adaptability in their printing endeavors, facilitating creative expression through diverse design options. The cost-effective nature of DTF methods makes them accessible for both small and large-scale production runs, eliminating the financial barriers often associated with traditional printing processes. Moreover, the compatibility of DTF with various materials ensures that businesses can meet the evolving preferences of consumers without compromising quality or sustainability. In this exploration, we unpack how DTF technology not only challenges conventional approaches but also represents a forward-thinking solution in today’s fast-paced market.

Understanding DTF Gangsheet Builder and Its Advantages

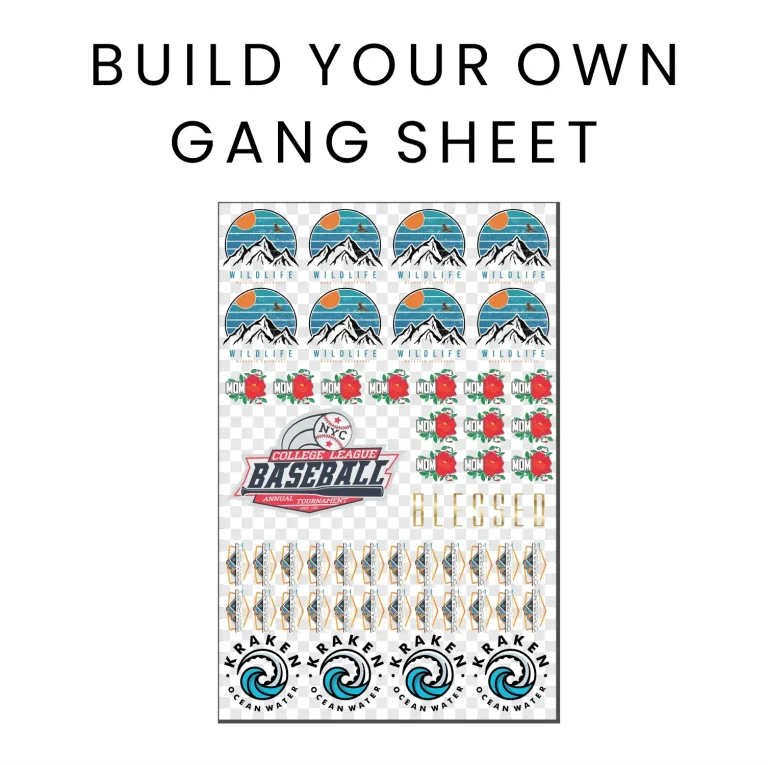

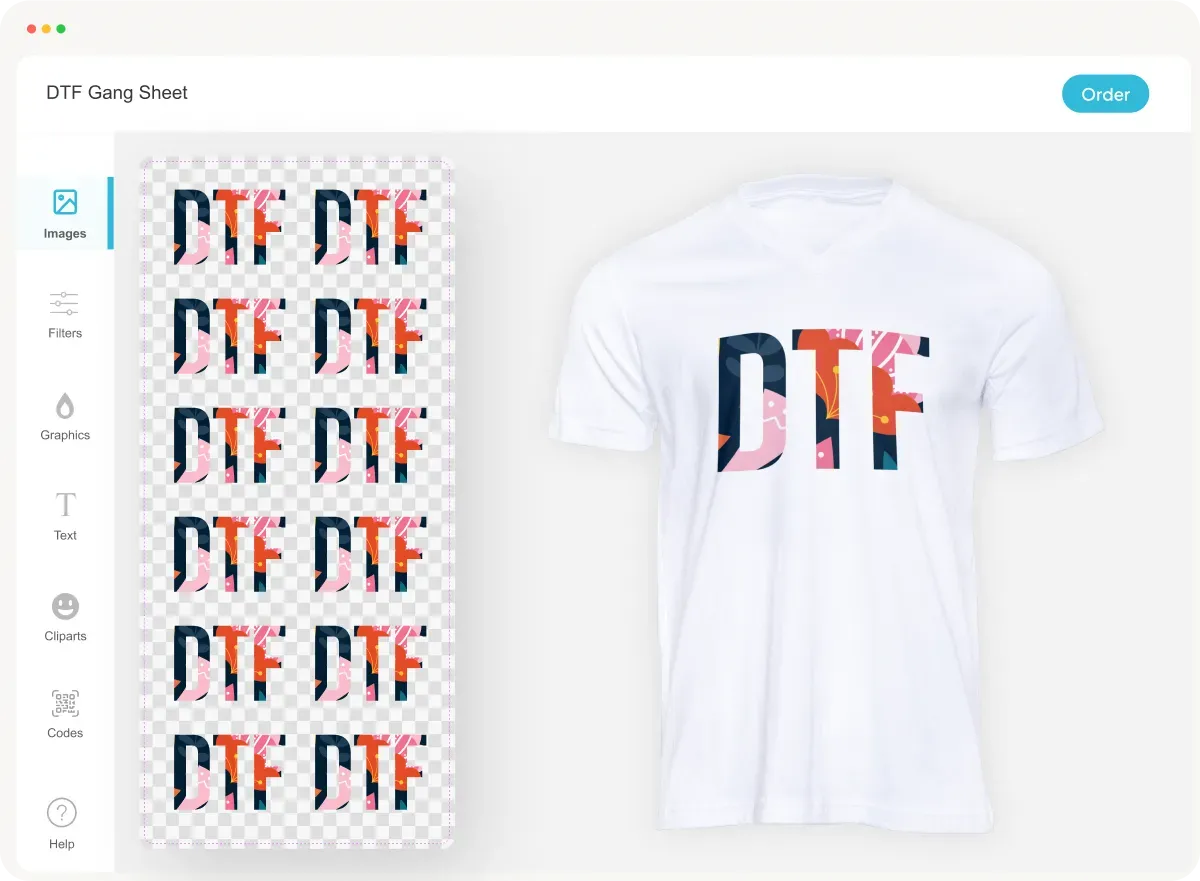

The DTF Gangsheet Builder is a revolutionary tool designed to optimize the printing process, allowing multiple designs to be printed on a single sheet of film. This method streamlines production, making it an ideal choice for businesses looking to maximize efficiency. By leveraging DTF technology, companies can significantly reduce setup times compared to traditional methods like screen printing, which often require detailed preparation and multiple setups for each design. The ability to handle several prints at once not only saves time but also minimizes waste, making the process more cost-effective.

Beyond efficiency, the DTF Gangsheet Builder also promotes creativity and design flexibility. Unlike traditional printing techniques that may limit color options and design intricacy, DTF allows for an extensive palette, giving designers the freedom to create vibrant and complex graphic mockups. This flexibility appeals to modern brands eager to differentiate themselves in a crowded market, ensuring that their printed materials stand out and resonate with consumers.

Cost-Effectiveness of DTF vs. Traditional Printing

When assessing the cost-effectiveness of printing methods, the DTF process stands out as particularly advantageous for businesses with smaller orders or diverse design requirements. DTF printing minimizes material waste and ink costs thanks to its ability to print multiple designs simultaneously on a gang sheet. For small to medium-sized enterprises, this represents a significant financial benefit, especially compared to the higher initial setup and labor costs associated with traditional printing methods like screen printing, which are better suited for large volume runs.

Furthermore, as noted in recent market analyses, the affordability of DTF technology does not compromise quality. Businesses adopting DTF can maintain high standards in their printed products without incurring the high overhead typically linked to traditional techniques. This competitive advantage is paramount for startups or businesses seeking to establish themselves without the financial burdens of older technologies.

Maximizing Design Flexibility in DTF Printing

The design flexibility offered by DTF printing is reshaping the landscape of graphic design in the textile industry. DTF technology supports high-resolution images and intricate color gradients, making it an exceptional choice for designers aiming for detail and depth in their work. Unlike traditional methods such as screen printing that may rely on simple color layering, DTF allows for full-color prints with complex designs—including photography, vivid color schemes, and fine patterns. This ease of implementation encourages more creativity and customization from graphic artists.

Moreover, with recent advancements in DTF printers and software, designers can accurately transfer their creative visions onto fabric without the constraints of traditional processes. This newfound design freedom aligns perfectly with consumer demands for personalized and unique products, making DTF an attractive option for modern brands that prioritize distinctive offerings.

Exploring Material Compatibility in DTF Printing

DTF printing is lauded for its exceptional material compatibility, allowing businesses to print on a wide array of fabrics such as cotton, polyester, and blends. This adaptability enables brands to cater to diverse customer preferences and broaden their product offerings without being restricted by the limitations of traditional printing methods. Such compatibility is essential in today’s garment production market, where consumer demand for varied and high-quality fabrics is rapidly evolving.

In contrast, traditional printing techniques often require specific inks or techniques tailored to individual fabrics, potentially causing complications in meeting urgent order demands. DTF’s ability to seamlessly transition between different materials enhances operational flexibility, empowering businesses to respond quickly to market trends and consumer preferences. Consequently, DTF printing not only streamlines production but also opens up numerous opportunities for brands looking to innovate their product lines.

Sustainability Trends in DTF Printing

As sustainability becomes an increasingly paramount concern within the textile industry, DTF printing is emerging as a responsible solution, consuming significantly less water and energy than traditional printing methods. The eco-friendliness of DTF inks aligns with consumer expectations for environmentally conscious business practices, making it a preferable choice for brands aiming to enhance their sustainability credentials. By adopting DTF, businesses can not only reduce their ecological footprint but also appeal to the growing segment of eco-aware consumers.

Additionally, the reduction in chemical waste associated with DTF processes supports the industry’s shift toward more sustainable practices. With traditional methods facing scrutiny for their environmental impacts, companies leveraging DTF are positioned to bolster their image as responsible market players. As industries increasingly prioritize sustainable solutions, adopting technologies like DTF will be critical for businesses wishing to thrive in a competitive landscape.

Recent Developments and Future of DTF Printing

Recent advancements in DTF printing technology indicate a bright future for the technique within the textile industry. Innovations such as improved RIP software and printer technology have enhanced printing quality, efficiency, and ease of use. New products and methods are continuously evolving, making DTF printing an attractive option for businesses exploring custom apparel. As more companies recognize the benefits of DTF, including speed and versatility, the demand for this method is anticipated to grow.

Furthermore, industry experts predict a shift towards DTF processes as they become integral to meeting modern consumer needs and preferences. As market trends reveal a gradual departure from traditional practices, embracing DTF technology will empower businesses to remain competitive while meeting the ever-evolving demands of the apparel market. Adopting such innovative methods will be crucial for success in an industry characterized by rapid change and increasing consumer expectations.

Frequently Asked Questions

What are the advantages of using DTF Gangsheet Builder over traditional printing methods?

DTF Gangsheet Builders provide increased production efficiency by allowing multiple designs to be printed simultaneously on a single sheet, significantly reducing setup times. Compared to traditional methods like screen printing, DTF technology minimizes downtime and maximizes material usage, making it an ideal choice for businesses requiring quick turnaround.

How cost-effective is DTF printing compared to traditional printing methods?

DTF printing is generally more cost-effective for small to medium runs, as it allows multiple prints on one gang sheet, reducing costs related to ink and materials. In contrast, traditional methods like screen printing often involve higher initial setup and labor costs, making DTF a more economical solution for companies with varying design needs.

What makes DTF Gangsheet Builder a flexible option for design in printing?

The DTF Gangsheet Builder offers superior design flexibility, supporting a wider range of colors and intricate designs without the restrictions seen in traditional screen printing. Enhanced RIP software used with DTF allows for better color accuracy and detailed layering, making it easier for designers to create visually captivating prints.

Which materials are compatible with DTF printing using a Gangsheet Builder?

DTF printing is compatible with various materials, including cotton, polyester, and fabric blends, providing versatility for different garment types. This adaptability allows brands to cater to diverse customer preferences, unlike traditional methods that often require specific inks suited for particular fabrics.

How does the sustainability of DTF printing compare to traditional methods?

DTF printing is considered more sustainable than many traditional printing methods, as it typically requires less water and energy consumption. Recent advancements have also led to the development of more environmentally friendly inks in DTF, aligning with the growing consumer demand for eco-conscious practices in the textile industry.

What recent trends in DTF printing should businesses be aware of?

Businesses should note the increasing shift towards DTF printing methods, driven by advancements in technology that enhance print quality and workflow efficiency. This trend reflects a broader industry transformation favoring DTF solutions for custom apparel, making it essential for companies to adapt to these emerging printing technologies.

| Key Points | DTF Gangsheet Builder | Traditional Methods |

|---|---|---|

| Production Efficiency | High efficiency with multiple designs printed simultaneously, reducing setup times. | Less efficient for short runs due to intricate setup processes. |

| Cost-Effectiveness | Economical for small to medium runs, reduces ink and material costs. | Higher setup and labor costs make it less attractive for small orders. |

| Design Flexibility | Extensive color range; ideal for complex designs and gradients. | Struggles with complex designs compared to DTF’s capabilities. |

| Material Compatibility | Compatible with various fabrics including cotton and polyester. | Limited to specific inks tailored for certain fabrics. |

| Sustainability Concerns | Consumes less water and energy; eco-friendly inks. | Higher environmental impact due to water usage and chemical waste. |

Summary

DTF Gangsheet Builder is revolutionizing the textile printing industry by offering unparalleled efficiency and flexibility compared to traditional printing methods. With its ability to produce multiple designs on a single sheet, it not only reduces time and resources but also provides a cost-effective solution for businesses of all sizes. The extensive design options and material compatibility further highlight the advantages of DTF printing, allowing brands to cater to diverse consumer needs. Moreover, the focus on sustainability in DTF processes positions it as a responsible and modern choice amidst growing eco-consciousness among consumers. As the market shifts toward more efficient and flexible printing solutions, adopting DTF Gangsheet Builders is essential for businesses looking to thrive in a competitive landscape.