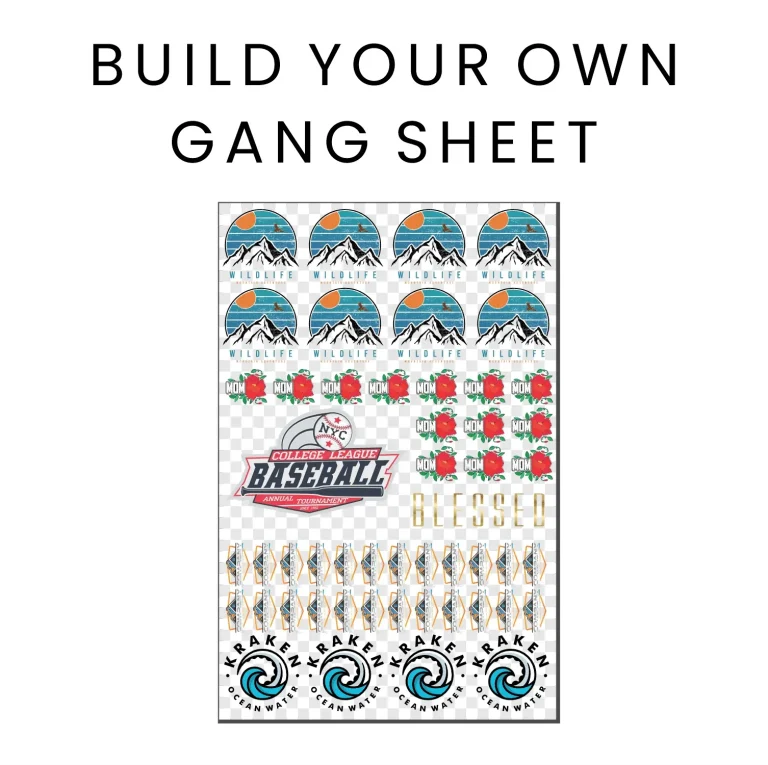

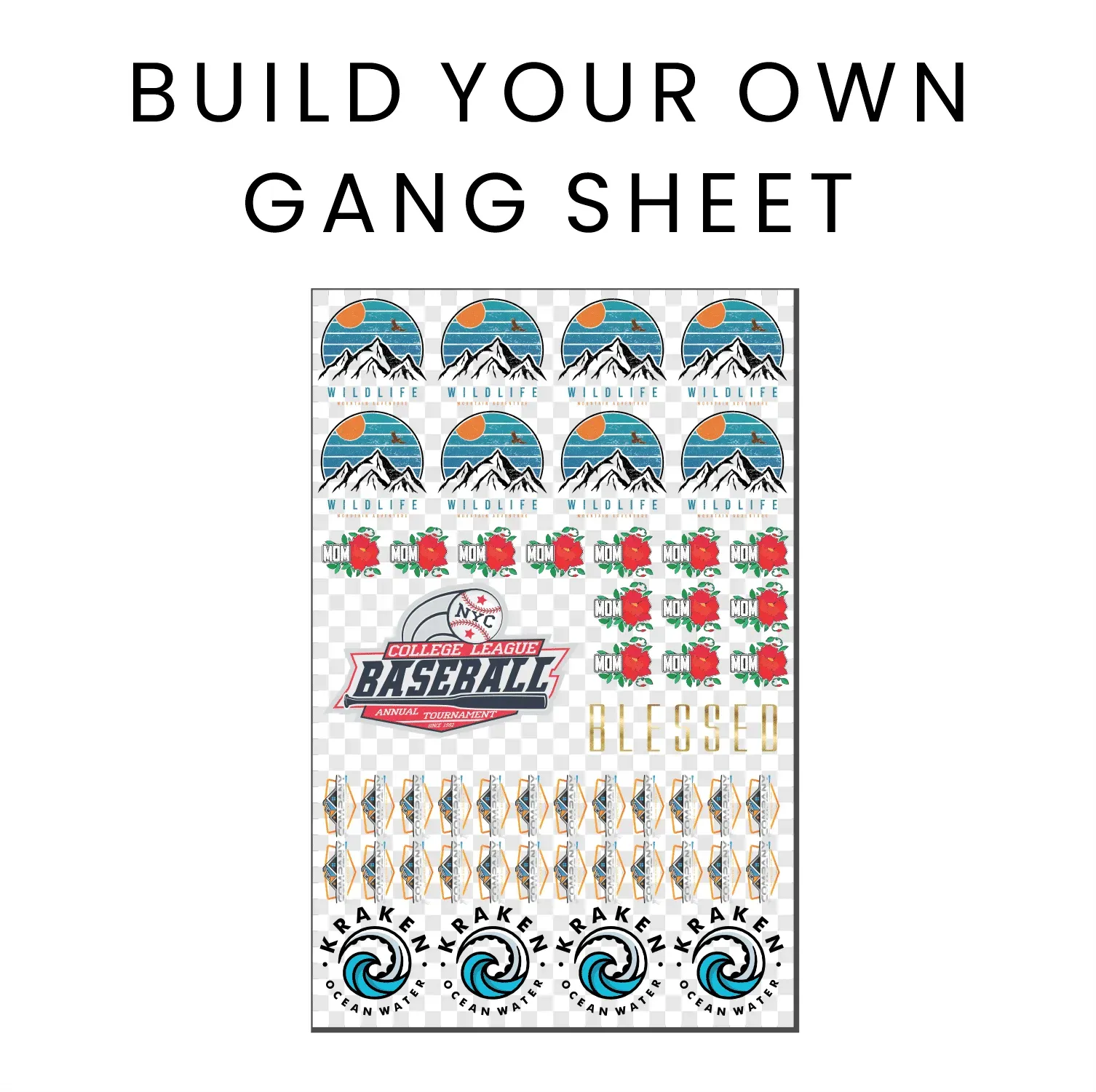

In the dynamic world of Direct to Film (DTF) printing, harnessing the capabilities of the **DTF Gangsheet Builder** is essential for both enthusiasts and professionals looking to improve their projects. This innovative tool simplifies the process of creating customized transfer sheets, allowing for a more efficient workflow and reduced material waste. By optimizing design preparation for DTF, users can easily achieve intricate layouts that maximize each sheet’s potential. Throughout this guide, we will outline key DTF printing tips and techniques that bring you closer to mastering the art of transfer printing. Whether you’re learning how to create an efficient gangsheet layout or exploring DTF transfer printing best practices, you’re on the right track to elevate your printing skills.

The DTF Gangsheet Builder serves as a focal point in the realm of transfer printing, especially as it revolutionizes how designers assemble multiple graphics onto a single film sheet. This advanced builder not only streamlines the design preparation process but also promotes a cost-effective approach by minimizing waste and optimizing the output of DTF printing settings. Many users appreciate its ability to facilitate efficient gangsheet layouts, enabling high-quality prints without excess material usage. As you delve into this exciting journey of DTF transfer printing, embracing best practices and tips will significantly enhance your outcomes and creativity.

Mastering DTF Printing Tips

When venturing into the world of DTF printing, equipping yourself with essential tips is crucial for successful outcomes. To optimize your printing process, start by focusing on image quality and preparation. Always ensure your designs are in high resolution, ideally 300 DPI, to maintain clarity and vibrancy on fabric. Additionally, configuring your designs in CMYK color mode will provide accurate color reproduction, as this is the standard used by DTF printers.

Furthermore, understanding common pitfalls and how to avoid them can elevate your DTF printing game. Issues such as incorrect file formats can hinder the quality of transfers, so it’s essential to utilize formats like PNG or SVG that support transparency and scalability. These foundational tips will significantly impact your ability to execute impactful and precise prints, setting the stage for a successful printing journey.

Effective Design Preparation for DTF

Design preparation is a vital step in the DTF printing process, ensuring that your prints come out as envisioned. It’s important to organize your designs meticulously before uploading them into the DTF Gangsheet Builder. This includes adjusting color profiles and verifying that all elements are vector-based or rasterized correctly to avoid any complications during printing. Keeping your designs clean and well-layered can drastically affect the final results.

Additionally, consider the compatibility of your designs with the printing medium. Test designs on similar materials can provide insights into how colors and details will reproduce. By preparing your designs with careful attention to detail, you’ll position yourself to create stunning prints that truly reflect your creative vision.

Creating an Efficient Gangsheet Layout

The efficiency of your gangsheet layout is paramount when using the DTF Gangsheet Builder. Effective nesting of designs not only maximizes the use of transfer media but also minimizes waste. By adjusting the arrangement of designs, you can ensure that each inch of the sheet is utilized effectively, allowing you to print more items with less wasted material.

Utilizing the nesting feature of the DTF Gangsheet Builder can streamline your workflow significantly. Automatic arrangement helps in reducing the time spent on manual layout, giving you more time to focus on creativity. Moreover, a well-planned gangsheet layout contributes to the overall quality of the transfers, ensuring consistent outcomes across prints.

Best Practices for DTF Transfer Printing

Implementing best practices in DTF transfer printing is essential for achieving high-quality results. Before committing to a full production run, conduct thorough test prints. This should include calibrating your printer settings, such as temperature and pressure, based on the material you’re working with. Adjusting these settings according to the specific transfer film and fabric can make a significant difference in the durability and clarity of the prints.

Moreover, color testing is a critical aspect of best practices. Ensure that your design colors match your expectations before executing a larger batch. This process can help identify discrepancies early on, allowing for adjustments to be made and preventing wasted materials, thereby enhancing the efficiency and quality of your printing operation.

Optimizing DTF Printing Settings

Optimizing your DTF printing settings is a critical phase in ensuring both quality and efficiency. A good starting point is to review your printer’s manual for recommendations tailored to the direct-to-film process. Experiment with varying pressure and temperature settings, as these can greatly influence the adhesion and vibrancy of your printed designs.

In addition, continuously refine your settings based on outcomes from previous prints. Documentation of settings used for different materials can help you quickly adapt to new substrates, ensuring consistent quality. This reflective practice will empower you to improve your techniques and adapt to future DTF printing challenges.

Engaging with the DTF Printing Community

Engaging with the DTF printing community can provide a wealth of knowledge and inspiration. Online forums and social media groups dedicated to DTF printing are excellent resources for newbies and seasoned pros alike. By participating in discussions, you can share experiences, seek advice, and learn about the latest tips and trends in the industry.

Moreover, showcasing your designs within these communities not only opens the door for valuable feedback but also fosters connections with fellow creators. Staying informed about new updates, features, and best practices shared by others can keep your skills sharp and your printing solutions innovative. Networking with like-minded individuals will enrich your printing journey, inspiring your artistic endeavors.

Frequently Asked Questions

What are the best DTF printing tips for beginners using the DTF Gangsheet Builder?

For beginners utilizing the DTF Gangsheet Builder, the best DTF printing tips include ensuring high-resolution designs (300 DPI), using CMYK color mode, and selecting the right file formats like PNG or SVG. These foundational steps help in achieving clarity and quality in your prints.

How can I optimize DTF printing settings when using the DTF Gangsheet Builder?

To optimize DTF printing settings with the DTF Gangsheet Builder, start by calibrating your printer for temperature and pressure and run test prints to ensure color accuracy. Adjust your settings based on feedback from smaller test designs to minimize costs and enhance print quality.

What is the importance of efficient gangsheet layout when using the DTF Gangsheet Builder?

Efficient gangsheet layout is crucial when using the DTF Gangsheet Builder as it maximizes the use of transfer media, ensuring you fit more designs per sheet with minimal waste. This not only saves material costs but also streamlines your production process.

How should I prepare my designs for DTF printing with the DTF Gangsheet Builder?

To prepare your designs for DTF printing using the DTF Gangsheet Builder, ensure that files are in high resolution (300 DPI), set to CMYK mode, and saved in appropriate formats such as PNG or SVG. Proper design preparation is key to achieving high-quality transfers.

What are some DTF transfer printing best practices when using the DTF Gangsheet Builder?

Some best practices for DTF transfer printing with the DTF Gangsheet Builder include organizing and naming layers clearly for easy management, conducting color tests for accurate output, and utilizing the nesting feature to reduce media waste and optimize layout.

How can I engage with the community to improve my DTF printing skills using the DTF Gangsheet Builder?

Engaging with the DTF printing community can improve your skills significantly. Join forums and social media groups where you can ask questions, share your designs for feedback, and stay updated on new tips and features related to the DTF Gangsheet Builder.

| Key Point | Description |

|---|---|

| Introduction to DTF Gangsheet Builder | A specialized tool for DTF printing that enhances design efficiency and reduces media waste. |

| Benefits of Using DTF Gangsheet Builder | Automation of design layout, cost savings through reduced material usage, and improved quality control. |

| Tips for Effective Use | Prepare designs, utilize nesting, manage layers, conduct test prints, and engage with the community. |

| Design Preparation | Use high-resolution images in CMYK format and preferred file types (e.g., PNG, SVG). |

| Nesting Feature Benefits | Minimizes waste, increases design capacity per sheet, and allows for quick layout adjustments. |

| Layer Management | Organize layers effectively with appropriate naming for better output quality. |

| Testing Settings | Calibrate printer settings with test prints for accuracy in larger projects. |

| Community Engagement | Participate in forums for advice, feedback, and staying updated on DTF trends. |

Summary

The DTF Gangsheet Builder is an essential tool that transforms the DTF printing experience from novice attempts to professional-quality outputs. By understanding the tool’s capabilities and applying effective strategies such as preparing designs correctly, leveraging the nesting feature for increased efficiency, managing layers for clarity, and performing consistent testing, users can significantly enhance their printing processes. Engaging with the DTF community provides additional resources and support, keeping you informed about industry advancements. With these methods, users will elevate their skills and create stunning designs that truly showcase their artistic vision.