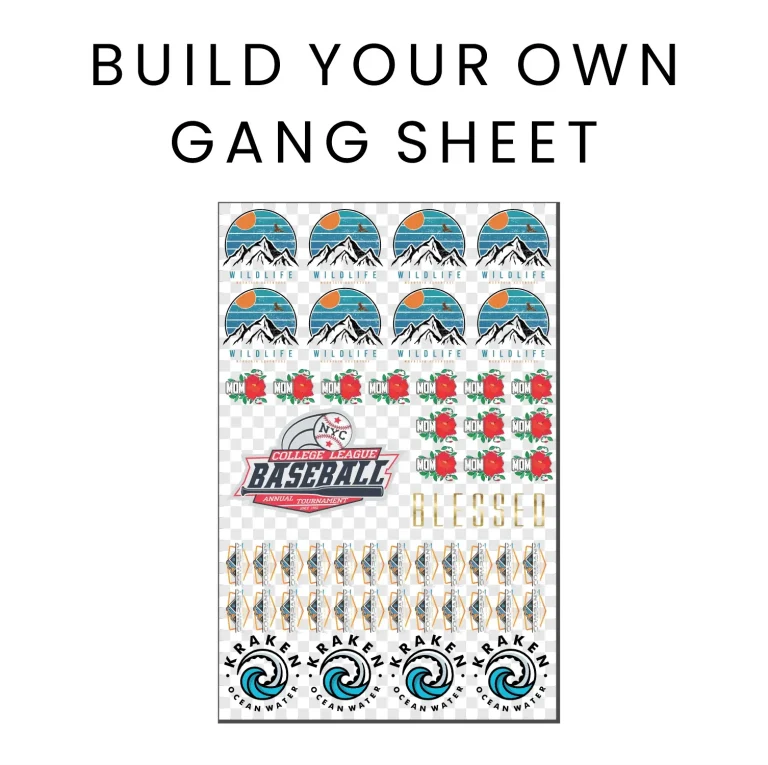

DTF GangSheet Builder reshapes how shops place multiple designs on a single sheet, unlocking faster turnaround and tighter control. From daily throughput to waste reduction, the tool affects DTF printing efficiency and the gang sheet printing workflow. Compared with manual layout for DTF printing, it can automate grid creation, alignment, and spacing, while preserving margins and color separations. This introductory overview supports comparing DTF layout methods and highlights measurable benefits like setup time, consistency, and cost per unit. By the end, you’ll see how the DTF GangSheet Builder stacks up against alternative methods and what to measure to justify the investment.

Think of this as a layout automation tool for multi-design printing on transfer films, designed to batch designs and optimize sheet usage, sometimes described as a DTF gang sheet builder. If you’re evaluating how designs are arranged, you might call it a batch-layout optimizer, offering predictable placement, color management, and faster proofs. In practice, such a solution complements manual adjustments and helps maintain brand consistency across high-volume runs.

DTF GangSheet Builder vs Manual Layout: Impact on Gang Sheet Printing Workflow and DTF Printing Efficiency

In DTF printing, automating layout with a DTF GangSheet Builder reshapes the gang sheet printing workflow. By automating grid creation, alignment, spacing, bleed, and color separations, the builder reduces repetitive tasks and minimizes errors, often boosting DTF printing efficiency and allowing operators to focus on quality checks and proofing. When set up with standard templates and calibrated color profiles, it also increases throughput by packing more designs per sheet without sacrificing print integrity.

Manual layout remains valuable for small runs or highly custom arrangements, offering greater creative control. However, it is labor-intensive and prone to human error, especially at scale, with risks of misregistration, wasted ink, and inconsistent margins. For shops handling many colorways or recurring templates, the trade-off leans toward automation; for bespoke orders, the manual approach can still excel, provided you invest in meticulous pre-press checks and skilled operators. This is where the phrase ‘manual layout for DTF printing’ captures the ongoing balance between flexibility and efficiency.

Measuring ROI and Throughput: Practical Guidelines for Comparing DTF Layout Methods

To decide between DTF GangSheet Builder and manual layout, measure metrics that reflect both throughput and cost: throughput per sheet, material usage and waste, setup and proofreading time, error rate, and long-term ROI. A formal comparison helps quantify DTF printing efficiency across batches and ensures you optimize a gang sheet printing workflow that aligns with your production targets. When you explicitly frame ‘comparing DTF layout methods’ as part of a pilot, you can assess how automation impacts repeatability, color consistency, and overall quality.

Implementation steps: establish baseline with manual layout for a representative run, create a pilot with a DTF GangSheet Builder using standard templates, then compare results on ROI, throughput, waste, and rework. Use a hybrid approach when needed, using the builder to establish baseline layouts and applying manual refinements for unique placements. This aligns with best practices to optimize your gang sheet workflow while preserving flexibility for creative or one-off orders.

Frequently Asked Questions

What is the impact of using the DTF gang sheet builder on the gang sheet printing workflow and DTF printing efficiency versus manual layout for DTF printing?

Automating with the DTF gang sheet builder typically improves the gang sheet printing workflow by handling grid, alignment, and spacing, which boosts DTF printing efficiency and reduces setup time compared with manual layout for DTF printing. It yields more consistent results for high-volume runs and minimizes waste. Manual layout still offers flexibility for unique designs, but it tends to be slower and more error-prone at scale. To decide, run a quick pilot to compare throughput per sheet, material use, and rework costs between the two methods.

When comparing DTF layout methods, how does the DTF gang sheet builder fare against manual layout for DTF printing in terms of throughput, waste, and consistency?

When comparing DTF layout methods, the DTF gang sheet builder generally provides higher throughput and more consistent results for bulk orders, thanks to automation and optimized bleed and margins. Manual layout offers greater creative control for bespoke designs but can introduce variation between sheets and longer pre-press times. Many shops use a hybrid approach: automation for standard sheets plus manual tweaks for special placements. To choose, measure throughput per sheet, waste, setup time, and rework across representative batches.

| Aspect | DTF GangSheet Builder (Key Points) | Manual Layout (Key Points) |

|---|---|---|

| Definition | Automates layout of multiple designs onto a single sheet, optimizing printable area, reducing waste, and speeding throughput. | Hands-on arrangement using rulers and a designer’s eye to place each design. It offers greater creative control but is labor-intensive and prone to human error at scale. |

| Core differences (Automation, density, consistency, color management) | Automates grid creation, alignment, and spacing; reduces repetitive tasks; deterministic results; color-safe templates and separations. | Relies on human judgment with flexibility; potential variation between operators; color accuracy depends on operator skill. |

| When to Use (Builder) | High-volume or repeatable orders; Complex layouts or many colorways; Need for consistency across runs; Tight production schedules. | N/A (Manual layout remains relevant for small runs, bespoke designs, or when automation ROI is unclear). |

| When to Prefer Manual | N/A (Builder is typically preferred for larger, more complex batches). | Small runs or custom orders; Limited budget for software or training; Creative or ambiguous placements; Frequent design changes. |

| Practical Evaluation Metrics | Throughput per sheet; Material usage and waste; Setup and proofreading time; Error rate and rework; Training and maintenance; ROI. | Same metrics are used to compare both methods. |

| Best Practices | Builder: Define standard templates, safe areas and bleed; calibrate color profiles; library of approved layouts. | Manual: Standard pre-press checklist; precise measurement tools; batch proofs; maintain log of layout decisions. |

| ROI & Long-Term Considerations | Automation reduces operator fatigue, improves accuracy across large batches, and enables scaling without proportional headcount. | Manual layout remains viable with limited budgets, smaller volumes, or highly bespoke orders. |

| Hybrid Approach | Hybrid workflows can combine strengths: use builder for baseline layouts and apply manual refinements for one-off designs. | Hybrid can offer rapid baseline layouts with flexible final adjustments. |

Summary

DTF GangSheet Builder stands out as a transformative solution for modern print shops looking to optimize throughput, reduce waste, and maintain consistent color across batches. By comparing automation with manual layout, shops can tailor a workflow that balances speed, accuracy, and flexibility. A practical evaluation framework—tracking throughput, material usage, setup time, error rate, and ROI—helps identify where automation yields the most value while preserving the creative freedom of bespoke orders. Whether you adopt a primary builder-driven approach or reserve manual layout for unique runs, the goal is to align your process with production goals, continuously measure performance, and adapt as designs and volumes evolve to maximize profitability and quality.