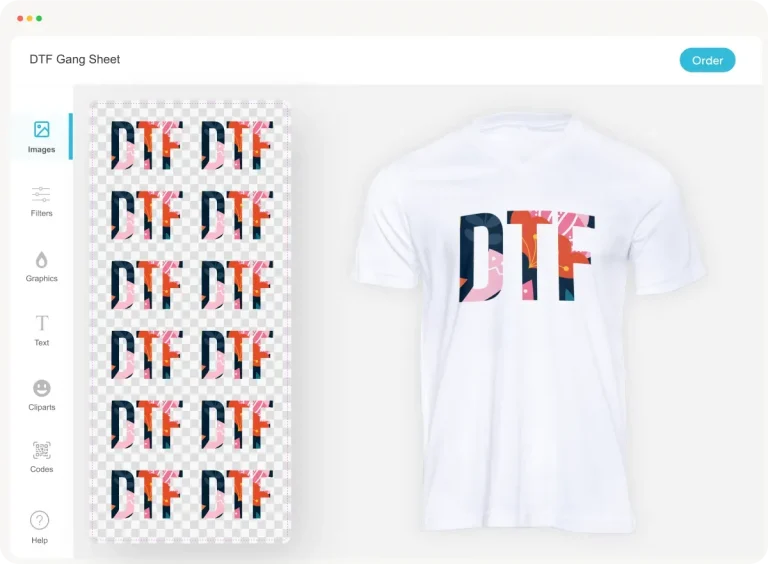

DTF Gangsheet Builder transforms how shops approach transfer designs, speeding up setup and cutting material waste. It streamlines the DTF printing workflow by automatically arranging designs into efficient gang sheets. As gangsheet design software, it automatically sizes, spaces, and aligns artwork to maximize material optimization. The result is greater print shop efficiency, with fewer errors and faster throughput. For scalable growth, it enables DTF production optimization by standardizing layouts and export-ready files.

Viewed through a different lens, this kind of layout automation acts as a gangsheet orchestration tool that groups designs for optimal material use. You can think of it as a prepress optimization solution that translates artwork into print-ready sheets with precise margins and bleed control. By coordinating multiple designs on a single sheet, shops improve production planning, reduce setup time, and maintain consistency across runs. In practice, operators benefit from templates, color management, and traceable outputs that support scalable, repeatable production.

DTF Printing Workflow Optimization with Gangsheet Design Software

Leverage the DTF printing workflow by using gangsheet design software to batch multiple designs into a single sheet, automatically tile them, and generate print-ready layouts. This approach streamlines pre-press tasks, reduces setup time, and minimizes misalignments, directly boosting print shop efficiency as you scale production.

Material optimization starts with packing designs tightly on the gang sheet, managing bleed margins, and optimizing color separations. By tailoring layouts to transfer film width and garment types, the software drives DTF production optimization and minimizes waste across batches.

DTF Gangsheet Builder: Boosting Throughput and Consistent Quality

The DTF Gangsheet Builder automates batch creation, auto-scaling and spacing, and export of cut lines and registration marks. By handling these steps automatically, you reduce setup time, increase throughput, and create a smoother hand-off from design to RIP to press.

With template libraries, color management integration, and material-aware layouts, you achieve consistent output and predictable results. This strengthens print shop efficiency and demonstrates practical DTF production optimization across orders of varying size and complexity.

Frequently Asked Questions

What is a DTF Gangsheet Builder and how does it improve print shop efficiency and material optimization within the DTF printing workflow?

A DTF Gangsheet Builder is gangsheet design software that organizes multiple designs onto optimized gang sheets, automatically sizes and spaces each design, and generates print-ready layouts plus production data. In the DTF printing workflow, it reduces setup time, increases sheet occupancy, and minimizes material waste through efficient layout, bleed control, and color management. It also standardizes processes for consistent output and supports DTf production optimization across jobs.

What features should I look for in DTF gangsheet design software to maximize DTF production optimization and ROI for a growing shop?

Key features include a drag-and-drop layout editor with auto-tiling, a template library for recurring designs, and integrated color management compatible with common RIPs. Look for material-aware optimization that adapts layouts to film width and garment types, support for multi-page gang sheets, and exports with cut lines and registration marks. Cloud or local storage with version history, plus easy integration with your existing design software, RIP, and printers, help accelerate adoption. Start with a pilot to measure ROI by tracking setup time, material waste, and output per hour.

| Key Point | Summary |

|---|---|

| What is a DTF Gangsheet Builder |

A DTF Gangsheet Builder is specialized software or workflow tool that organizes individual designs into efficient gang sheets, automatically sizes and spaces each design, and generates print-ready layouts along with the associated production data. The result is fewer failed starts, less wasted material, and a smoother hand-off between design, RIP, and press. |

| Core benefits |

|

| How it saves time in practice |

|

| Material optimization: how the builder cuts waste |

|

| Scaling your print shop |

|

| Choosing the right features |

|

| Best practices to maximize ROI |

|

| A practical example: estimating impact |

|

| Common questions and tips |

|

Summary

DTF Gangsheet Builder is a strategic platform for scaling your print shop. By optimizing layouts, reducing material waste, and streamlining the pre-press process, it delivers improved efficiency and stronger margins. The right tool helps you transform your production flow into a reliable, scalable system, enabling you to take on bigger orders, meet tighter deadlines, and deliver consistent quality across every transfer. If you’re aiming to save time, conserve materials, and grow your business, investing in a DTF Gangsheet Builder is a practical move that aligns with modern, data-driven print production.